No conductor in an electrical circuit can be infinite in length. Sooner or later, it must be connected to another wire, power source or consumer communication equipment. One way or another, but there is a need for a forced connection between several conductors or equipment.

Ways of connecting conductors

There are several options for connecting conductors:

- twist;

- soldering;

- crimping

- using ready-made devices.

Twisting and crimping is a cold connection method. Soldering is carried out at high temperatures.Each method has positive and negative aspects, which we will dwell on below, starting with the simplest connection - twisting.

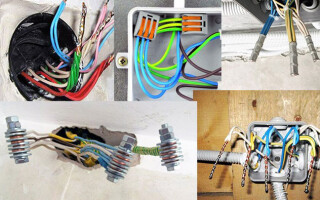

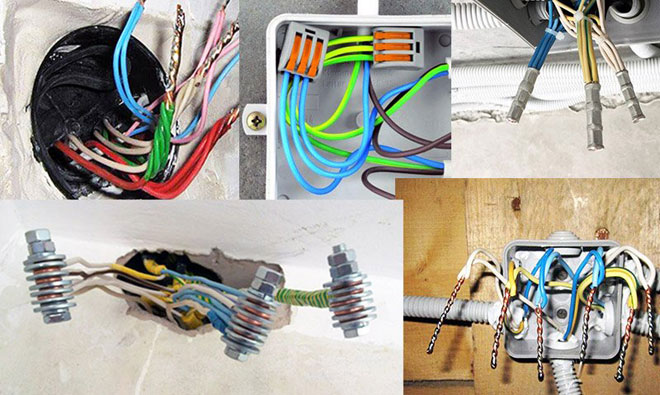

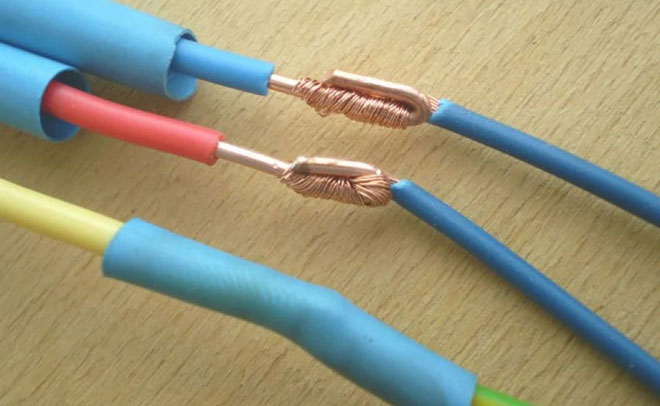

Twisting

This method is not considered correct and not one competent electrician does not recognize it. The reason is the fragility of the connection, which can loosen when touched or vibrated. This connection is especially unacceptable for conductors of large cross-section or when three single or stranded wires come into contact. This option can be used as a temporary connection of lighting lines.

Technologically, the twist looks like this. The conductors are stripped to a length of up to 3 cm from oxides on the surface, and then twisted together. Be sure to apply insulation to the place of twisting.

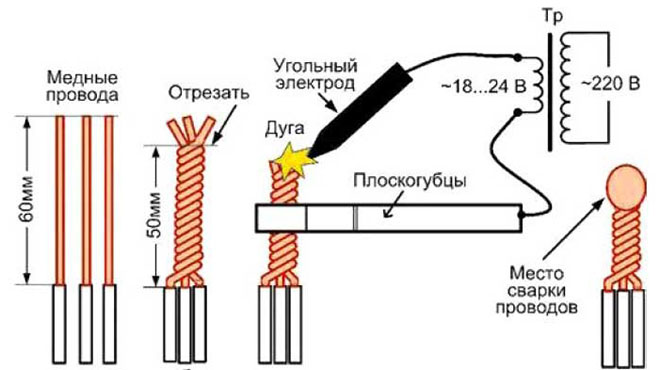

Soldering and welding

Another way is soldering or welding, which are perhaps the most reliable, but the most technically complex processes. Soldering technology begins similarly to the previous method. The surface of the conductors is also cleaned, and after that they are either twisted or pressed tightly against each other. After they warm up and solder is supplied, which can be either soft or hard.

Of the soft solders, tin-lead or silver solders are well known, with a low silver content. Refractory include copper-phosphorus, silver, brass, and zinc. Hard grades of solders are more often used when welding copper wires in industrial enterprises, since they need to be heated to very high temperatures, unlike soft grades, which melt well when heated with a conventional soldering iron. To improve the quality of soldering, fluxes or preliminary degreasing of contacts with acid are used.

Often, a welding torch or gas cutter is used to connect large-section copper conductors, which is a professional tool for a welder and cannot be used by an amateur.

Aluminum conductors are soldered using different technological equipment, using different grades of solder than copper wires. Argon soldering is often used. Soldering aluminum conductors is a rather complicated process, since the wires "float" under the influence of high temperatures. Places of soldering of aluminum and copper wires are cleaned from welding influxes and must be insulated.

Welding of conductors occurs according to the scheme indicated below.

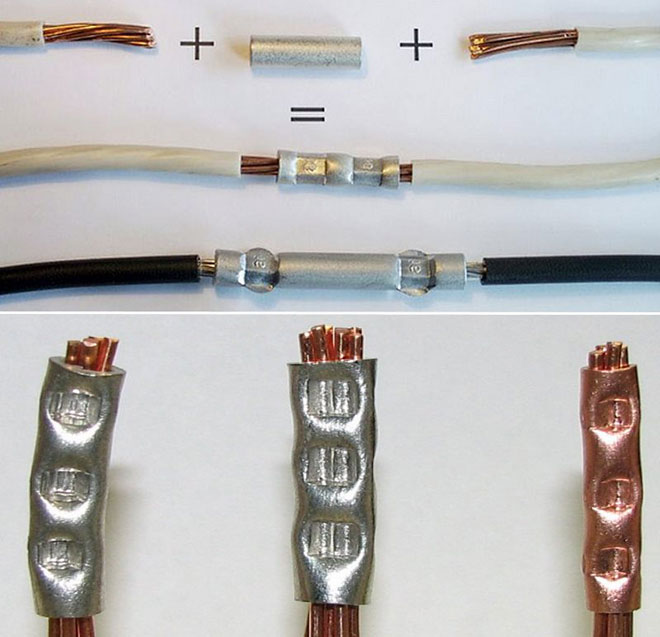

Connecting cable sleeves

When connecting stranded wires by crimping, crimping cable sleeves, which are a hollow tube, can be used. Before their use, the wires are stripped of insulation to a size of at least half of the sleeve. Then the sleeve is put on the conductors, and it is crimped on both sides with a special press. A bare, uninsulated place on the wire is insulated with a call to the wire and the sleeve.

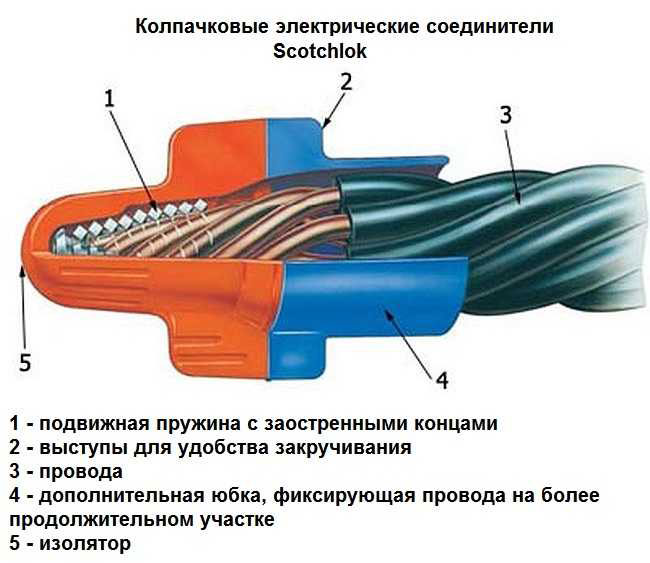

Connecting insulating clips

Connecting insulating clips or PPE are a ready-made connection solution. The wires are pre-stripped of insulation, twisted, and the clamp is screwed on top. The fixation of the contact is carried out by means of a conical coil spring built into the clamp.

It is not necessary to insulate the connection point, since the clamp cap itself is the insulation. Externally, the terminal caps may differ in shape for ease of installation. They also differ in size, taking into account the selection for the total cross section of the conductors.

Terminal blocks and terminal blocks

To assemble circuits and connect conductors in the desired sequence, terminal blocks or terminal blocksthat perform multiple functions at the same time. They fix conductors, allow you to assemble circuits and protect live parts from breakdown due to the insulating materials that they contain.

Outwardly, they represent a plastic case with sockets. Connected wires are fixed by screws or spring clips. Depending on the cross-section of the wire and the number of required clamps, they have different sizes.

Before mounting the conductor on the screw terminal block, it is stripped and looped onto the screw, and then tightened well with it, trying not to pinch the conductors. The quality of each contact is checked not only visually, but also by twitching the wire or testing with measuring instruments.

Spring terminal blocks are used for monolithic or crimped NShVI tips, stranded conductor.

The disadvantage of this type of connection is the impossibility of complete isolation, and with poor contact, the possibility of its oxidation. With prolonged operation of the contacts, their fixation on the block must be checked.

Clamping conductors between bolt and nut

This type of connection is typical for conductors of different metals and is quite simple. Initially, the insulation is stripped from the wires and a loop is made on the stripped wire. Loops are strung on the body of the bolt. Spring washers are used to prevent the nuts from moving. This fixation looks quite cumbersome and requires space, which is not always enough when assembling the circuit.

The reliability of the connection is ensured by the use of a metalwork tool. The reliability of fasteners is checked by twitching the wire.

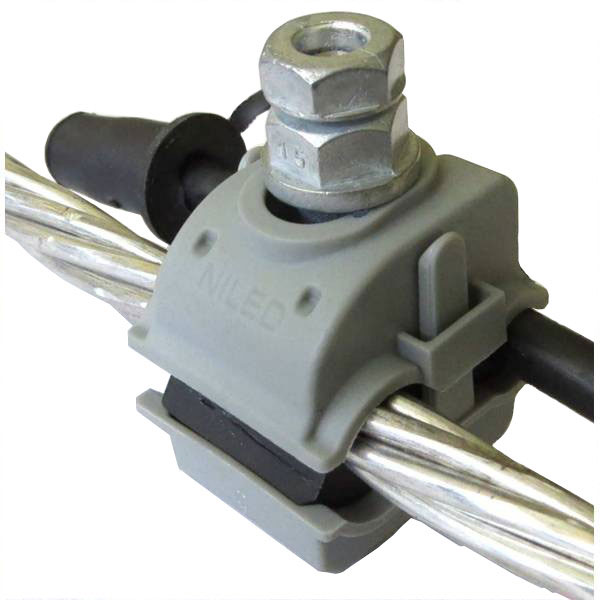

Piercing and tapping clamps

Piercing and tapping clamps are commercial products. They have two connectors. One under the core, which is under tension, the second - under SIP.

The clamping device has a bolt that is tightened with a key. The bolt actuates the contacts, which pierce the insulation of the conductive wire, thereby connecting the wires to each other. Finally SIP wires an insulating cap is put on to isolate the free edge of the wire, which is included with the clamps. Clamps allow work to be carried out under tension.

Connecting cable boxes

Connective cable box allows you to connect several pieces of cables without voltage with minimal loss of network power. In their device there are sleeves with bolted connections that allow you to fix the current-carrying parts of the ends of the cables to each other and reliable insulating materials. Couplings differ in their design. The most popular option with heat shrink insulation.

Selecting the method of connecting conductors

There are many ways to connect conductors. You need to choose the possible option taking into account the situation. So, if you need a temporary connection, you can simply twist or clamp the conductors between the bolt and nut. Shaped or winding wires of large cross section are best fixed by welding or soldering.

Splice sleeves or sleeves are ideal for splicing cables. Connecting insulating clamps are well suited for fixing small wires and with the right clamp size. Terminal blocks are needed to assemble the circuit.Piercing and branch clamps are used to connect an additional load to an existing network.

Connection of stranded and solid conductors

This connection starts with a section selection stranded wire to single-core. A stranded conductor must not be smaller than the cross section of a single conductor, otherwise it will burn out at the junction. They are fixed by soldering or welding, or by crimping when using cable sleeves.

When soldering, the wires are cleaned of insulation, then the stranded wire is wound onto a single-core wire, and then soldering is performed. Then the place of soldering is protected by insulation. When crimping, the contact points are cleaned, a sleeve is put on, which is crimped crimping press tongs in several places.

Connecting wires with a cross section of different diameters

The connection of wires with a cross section of different diameters is possible when calculating the current density in the sections, if the density in the sections is acceptable, then they can be connected by soldering, twisting, terminals or bolted connections. Connection technologies do not differ from the process of connecting wires with the same cross section and were discussed above.

Connecting larger wires

This method of connection is quite complicated with a large contact area. If the cross section of rectangular wires is too large, fixing is possible only by welding and often it is impossible to do it at home due to the need to heat the conductors to a high temperature. After welding the conductors, a mandatory test of the resulting contact is necessary.

When connecting stranded wires or large cables, you can use connecting cable sleevealready mentioned above.

Connecting broken wires in the wall

Often in everyday life there are situations when there is a breakdown of electrical wiring in the wall. Often this happens during renovations. Initially, the electrical wiring must be de-energized and the plaster dismantled at the repair site.

After that, the insulation is stripped from each end of the damaged wire, and the ends are covered with molten lead-tin solder using a conventional soldering iron. Isolation for the place of soldering is immediately thought out. It is good to use heat-shrinkable tubing, given the size of the area to be repaired. The tube is put on one of the ends of the conductors.

Next, a wire with a cross section not less than the broken wire is selected, it is cut off and soldered first to one end of the wire, then to the other. At the same time, the length of the extended conductor must ensure the strength of the contacts. It should not be too small or long. In conclusion, a tube is put on the area, which, when heated with a hairdryer, tightly wraps around the soldered area.

Combination of copper and aluminum

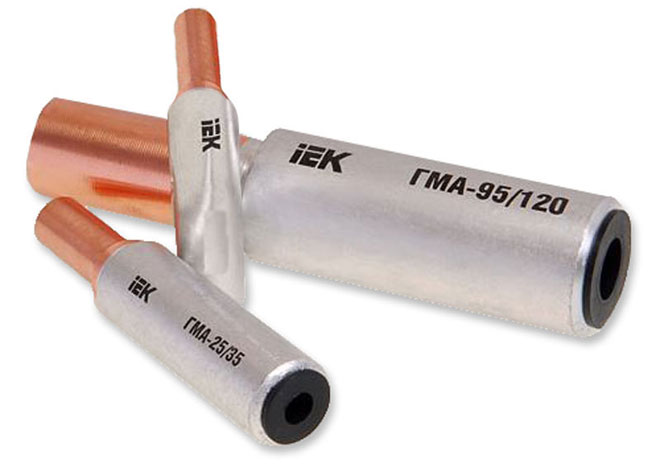

How to connect copper and aluminum wire is discussed in more detail in our article. The connection of dissimilar wires is possible by the bolted connection discussed earlier. However, most often fixation is performed using copper-aluminum sleeves (GAM) for pressure testing. On the one hand, the sleeve is made of aluminum, on the other hand, copper. The aluminum side of the sleeve is larger because aluminum has a lower current density than copper. The sleeve is put on the ends of the wires with the same metal and crimped with a press.

Similar articles: