For the transmission of electrical energy through power and lighting overhead lines, a self-supporting insulated wire is used (SIP). Lines using this type of cable were invented in the 60s by Finnish engineers as an alternative to using bare wires that were hung on cables. This method of power transmission ensures minimal losses and is suitable for installation on existing transmission poles.

Content

Application area

Self-supporting insulated wire is used in the construction of lines from the main main wires and step-down transformer substations to various buildings and structures and lighting networks in settlements. Such a cable can be used in various climatic conditions, including aggressive environments.SIP is actively used in conditions of dense development between buildings and structures.

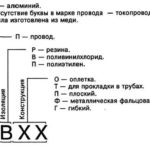

Type marking and decoding

According to GOST 31946-2012 "Self-supporting insulated and protected wires for overhead power lines" SIP cable is made of thermoplastic light-stabilized polyethylene, and the carrier cores are made of aluminum alloy and are divided into the following types:

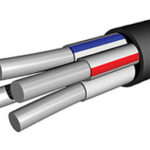

SIP-1 and SIP-1A

The most common and commonly used type of aerial cable. Due to its design, the insulation withstands core heating up to 90 °C during normal operation and even up to 250 °C during a short-term short circuit.

Structurally, it consists of 3-4 aluminum conductors covered with polyethylene insulation. The neutral wire is also made of aluminum alloy and has a steel core woven into the center of the cable. It can be isolated or non-isolated. If the cable is marked with the letter "A" at the end of the name, then the neutral conductor has polyethylene insulation (similarly for SIP-2A).

Marking decoding:

SIP-1 4*35 + 1*25 – self-supporting insulated wire with four current-carrying cables with a cross section of 35 mm2 with one uninsulated zero core section 25 mm2.

SIP-1A 4*25 + 1*16 – self-supporting insulated wire with four current-carrying cables with a cross section of 25 mm2 with one insulated zero core section 16 mm2.

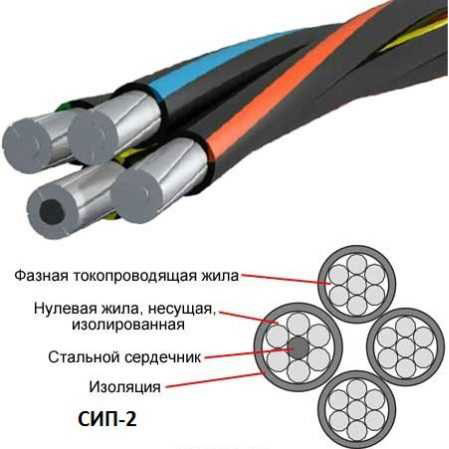

SIP-2

It differs from SIP-1 in the type of polyethylene insulation. The insulation is made with increased protective properties to mechanical damage and is very durable. Such an imported cable is marked 2F for a wire with a carrier core and 2AF - without it.

SIP-2 is used in any climatic zones and weather conditions, as well as when exposed to aggressive environments.

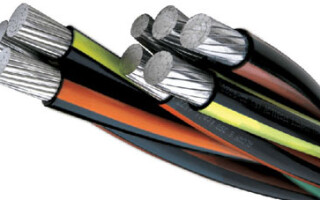

SIP-3

This type of cable is used in the construction of high-voltage lines with light-stabilized polyethylene insulation for 6-35 kV with a thickness of up to 3.5 mm. It has one stranded core with an aluminum core and can be used at low air temperatures without losing elasticity. Marked as follows:

SIP-3 1*185–35 kV – designed for AC voltage up to 35 kV and has a core of 185 mm2.

It is resistant to mechanical damage, aggressive media and low temperatures. The insulation can retain its properties during short-term overheating up to 250 °C.

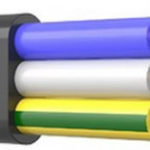

SIP-4

The main feature of the design of a self-supporting insulated wire of this type is the absence of a carrier core, only conductive. For this reason, the use of SIP-4 is somewhat different. It is used for short power transmission lines, for example, for power transmission, from a transformer substation to a building or structure, or for branching off large highways. For this reason, SIP-4 is often called a branch.

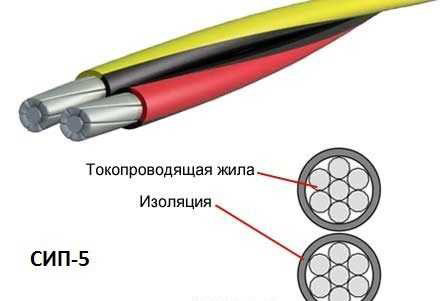

SIP-5

It is an analogue of SIP-4 and is visually similar to it. But the design of this type of cable still has differences: the insulation is made of non-combustible material and is able to withstand critical temperatures. It is used to transmit electric current with voltage up to 1000 V to buildings or street lighting.

Specifications

The cross section of the cores of the SIP wires has values from 16 to 185 mm2, is able to feed powerful consumers and pass currents up to 500 A through itself, and the permissible currents of one-second short circuits can reach 16 kA.There is a large selection of cable options in terms of cross-sectional dimensions and permissible current, so this wire is universal for building overhead lines.

The operating temperature ranges from -60 to +50 °C, and the wire version can be both for moderate and cold climates. Installation of SIP wire is possible at temperatures up to -20 °C.

The service life reaches 45 years and most manufacturers give a guarantee of up to 5 years.

A mechanical load from wind, ice, snow acts on such a cable, therefore such lines must be calculated by weight and the effect of mechanical loads on them. For such a calculation, data on the breaking force of the carrier cable are used, depending on the type, cross section and mass of the wire.

Cable structure

SIP-1 - consists of three phase current-carrying conductors and one zero. Each phase is a bundle of several aluminum conductors twisted around an aluminum core. Phase conductors are insulated with polyethylene, zero - without insulation, inside the core has a steel core.

SIP-2 - differs from SIP-1 in isolation. It is made of cross-linked polyethylene and is very durable to mechanical and thermal influences. In addition, the neutral conductor is insulated, as well as the phase conductor.

SIP-3 - a single-core wire that has a steel core around which wires made of an alloy of aluminum, copper and other additives are twisted. It has a wide range of cross-sections and is capable of operating in high-voltage networks when exposed to mechanical loads and harsh climates.

SIP-4 – does not have a neutral wire and consists of several pairs of aluminum alloy cores with UV-resistant insulation.

SIP-5 - has a similar SIP-4 design, but differs by 30% increased strength and resistance to various influences (mechanical, atmospheric, etc.) for insulation.

Installation of SIP cable

Installation of SIP cable is possible both on old poles of power lines, and on the facades of buildings in settlements. No special insulators are required for fixing.

SIP is mounted to the facades of structures on special fasteners, anchors and clamps, suspended from the lines on intermediate clamps. For the device of branches, special powerful clamps are used, depending on the cross section of the wire.

During installation, it must be taken into account that the entry point into the building must be at a height not less than 2.7 m from the surface of the earth, and the gap to the lowest point of sag between the pillars not lower than 6 m. The main support should be located from the facade of the building no further than 25 m, and the location of the branch support should be no more than 10 m from the facade or wall of the building.

Due to the fact that the installation of the SIP wire is associated with high currents and high-voltage lines, it must be installed strictly in accordance with the electrical regulatory and technical documentation and only by qualified personnel in compliance with all norms and rules of labor protection and safe work.

Advantages and disadvantages

The advantages of the wire are:

- Reducing the number of losses due to cable insulation;

- Resistance to mechanical damage, climate, aggressive environments and various temperatures;

- Does not allow illegal connection to highways;

- There is no overlap and, as a result, short circuits from the effects of wind;

- Large selection of types and cross sections;

- Easier and faster installation, which can be carried out at low temperatures and under various weather conditions;

- Good flexibility of SIP and elasticity of insulation in various temperature environments;

- Does not require the installation of insulators for mounting on poles and buildings;

- Safe for maintenance and operation;

- Requires fewer poles when installing overhead lines;

- No corrosion;

- It is possible to carry out the installation of SIP on the walls of buildings and structures;

- Long service life.

SIP also has its drawbacks:

- A large mass of the cable due to the presence of a carrier core and thick insulation;

- High cost of production;

- The need for specially trained qualified personnel for the installation and operation of such cable overhead lines.

The SIP wire has more advantages than disadvantages and is a modern and technologically advanced electrical cable for the installation of overhead lines for various purposes. It is produced by both domestic and foreign manufacturers of cable products. There are various wire options on the market according to insulation properties and permissible current, which allow you to choose the necessary wire for specific tasks and building electrical networks of varying complexity and power, as well as the environmental conditions in which they will work.

Similar articles: