Circuit connections provide the least current loss. They are performed in different ways - twisting, soldering, welding. Use terminals for wires - devices that are easy to install, ensuring the reliability of electrical contact.

Content

How to connect wiring

They do this in several ways. The choice of method depends on the thickness, number of cores and metal of the conductor, the type of insulating material and the operating conditions of the connection.

In practice, the wires are connected:

- twist. The method is simple, does not require special tools - it is performed using pliers and a knife. Provides reliable connection, well resists vibration. Not recommended for twisting conductors of different diameters. Not suitable for conductors of various materials, multi-core cables.

- Welding. The method, like terminal clamps, is distinguished by reliability, strength, and durability of the connection. Provides complete fusion of conductors, optimal resistance of the splicing point.

- Soldering. Refers to reliable and durable types of connections. Guarantees the efficient operation of mechanisms, the safety of people who operate them. Suitable for devices that do not get very hot during operation.

- Crimping using sleeves. The way that the connecting terminals, available for domestic conditions, differ, is simple.

- With bolted contacts. The method provides a reliable connection of cores made of different metals.

- Screw terminals, spring terminals or terminal blocks.

Twisting. The ends of the wires to be connected are cleaned, removing the insulation in a section not less than 5 cm long. They are clamped with pliers and, performing a rotational movement, are twisted. The twist is folded to the side and insulated, wrapped tightly with electrical tape or covered with heat shrink tubing.

Soldering. The process begins with stripping and twisting the wires. Then they are tinned with rosin and filled with solder. The latter is lead or tin when soldering copper wires; zinc with copper, aluminum or tin - aluminum.

Welding. The connection of conductors is possible in one of its types:

- ray;

- arc;

- plasma;

- point;

- ultrasonic;

- torsion.

The method is complex, involves the use of a welding machine, and requires appropriate qualifications from electricians.

Sleeve pressing. The method uses soft metal sleeves. The stripped ends of the cores are inserted into them, then the tube is crimped in a vice or with pliers.

Connection by terminals, terminal blocks. The method, which is the easiest to implement, ensures reliable installation of the electrical network.It uses simple terminals to connect to a dielectric body and a brass alloy or copper connector. The method allows you to connect conductors of different metals without their direct contact.

Types of terminal blocks

3 types of devices are used:

- screw terminals;

- spring;

- knife.

Terminal blocks for connecting wires are made of brass alloy or copper. Some models come with chain breakers, filling the contact point with a gel that protects the connection from corrosion.

The requirements for clamps are:

- For thermal stability. All types of terminals must withstand high temperatures and retain their shape.

- By strength of fixation. All types of terminals for connecting wiring must securely hold the conductors, and the connection of the cores should be made with minimal effort. Additional twisting or processing of wires for screw or other types of terminals is not required.

- For resistance to corrosion. The length of the plates for detachable terminal blocks should exclude direct contact of the connected wires and electrochemical corrosion in the case of different materials of the latter.

- In terms of information. Clamp terminals are marked indicating the permissible voltage in the network and the diameter of the conductors that are connected by the device.

Advantages of switches:

- Easy to connect wires. The latter may be 2 or more. The conductors are placed in separate sockets and can be easily dismantled.

- Safety. The connection terminals are made of insulating material. It:

- eliminates electric shock when touched;

- allows you to work only with a suitable screwdriver.

- Reliability of the attachment point. It withstands mechanical and thermal loads, vibration, stretching.

- Aesthetics of places of conjugation of veins. Despite the fact that such a terminal block is made with many conductors, the view is neat.

Screw terminals

The elements are suitable for use in sockets, other similar devices. The wires are clamped in them with a screw. Aluminum conductors are not connected with screw terminals - pressure from fasteners leads to the destruction of aluminum conductors. The screw head of the grounding contact, if there is one in the screw terminal block, is marked with green paint.

Types of screw terminals:

- Tubular terminals for connection. The end of the stripped wire is placed in a brass or copper tube. The core is fixed with the end of the screw, the axis of which is perpendicular to the latter. The second conductor is inserted from the opposite end of the tube and pressed with another screw. In this type of commutator, the wire is clamped unevenly and can be damaged by the rotating screw. Because of this, it is recommended to use it for splicing single cores.

- Lamellar. They differ from the previous ones in the presence of a pressure washer or plate through which the wires are clamped with a screw. Connecting terminals ensure the integrity of current-carrying conductors, better contact. They can fix 2 conductors at once. For printed wiring, plate clamps are used:

- Petal type. Differ in a thin plate. Budget switch.

- Lift. The plate is embossed, which increases the reliability of the connection of wires with terminals, increases the contact area.

- TOR clamps. They have a special lever, which clamps the wire under the pressure of the screw.The switch can adjust the fixing force when connecting the terminal for connecting wires, improved tightness of the contact.

Terminal blocks for circuit boards are distinguished by the shape of the housing. They are:

- With embossed trim. An additional dielectric protection is arranged around the socket, which almost completely eliminates the possibility of a short circuit.

- With all round protection. They differ in the design of the terminals with a clamping part that completely encloses the wire. The latter does not allow the conductor to break out, improves the quality of the contact.

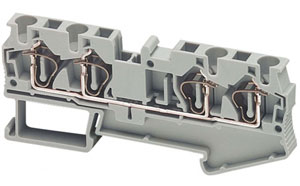

Self-clamping terminal blocks

A feature of such switches is quick installation. There is a special lever in the terminal device that acts on a small flat spring, which presses on the surface of the core with its entire plane. Instead of a spring, there may be a conductive knife, which, when clamped, cuts through the insulation of the conductor and abuts against it.

Terminal blocks how to use:

- raise the lever;

- insert the stripped end of the wire into the socket;

- lower the lever.

The types of clamps are different. Manufacturer Wago offers:

- Disposable. The cheapest switches that do not have a traditional lever. To fix the ends of the stripped wires, a lock is used inside the case. Terminal blocks are used more often for connecting single-core conductors.

- Reusable. They can be conductors of stranded wires. There are models with a special groove in the housing, through which the contact is monitored by a measuring device, the phase and zero of the mains are determined. Available for different connection conditions. There are series of devices for:

- wire connections in a wide range of cross-sections (1.5-4 mm²);

- lighting fixtures;

- networks with low current;

- splicing only copper wires.

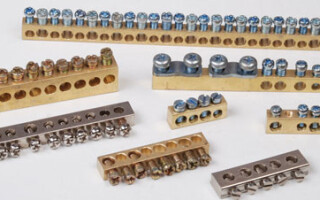

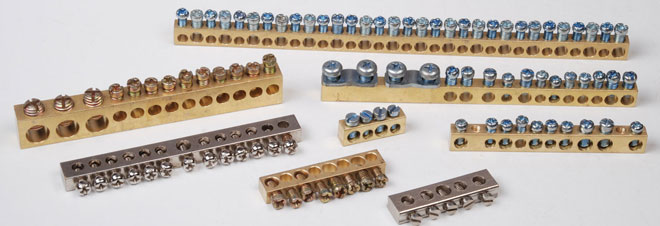

Terminal bars

Switches of this type represent a copper bus on which many screw terminals are placed. Terminal connections are designed to connect a large number of cores. They connect wires in junction boxes, lighting panels. Connectors connect neutral and ground conductors of different groups.

Connecting clamps

Cylindrical caps made of dielectric material with one end closed and female thread on the other open. Unlike blocks, terminal blocks for connecting wires require preliminary twisting of the cores. Then it is clamped by screwing the clamp on top.