Many amateurs and professionals use electrical equipment for various purposes in their work. And in many cases, electrical equipment is driven by three-phase motors. But a three-phase network is often not available in garage boxes and individual households. And then the schemes for connecting a three-phase motor to a single-phase network come to the rescue.

Content

What is a capacitor for?

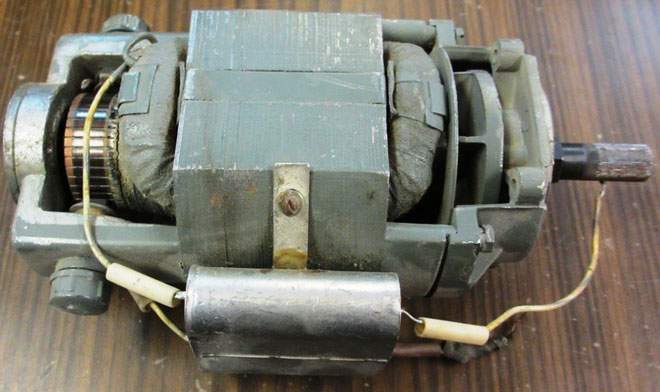

The most common and used in machine tools are three-phase asynchronous AC motors with a squirrel-cage rotor. We will consider their connection to a single-phase network. When the motor is connected to a three-phase network, an alternating current flows through three windings at different times. This current creates a rotating magnetic field, which begins to rotate the rotor of the motor.

When the motor is connected to a single-phase network, the current flows through the windings, but there is no rotating magnetic field, the rotor does not spin. A way out of this situation was found. The simplest and most effective way was capacitor parallel connection to one of the motor windings. The capacitor, receiving and releasing energy impulsively, creates a phase shift, a rotating magnetic field is obtained in the motor windings and it works. The container is constantly energized and is called working capacitor.

IMPORTANT! Correctly calculate and select the capacitance of the working capacitor and its type.

How to choose the right capacitors

Theoretically, it is supposed to calculate the required capacitance by dividing the current by the voltage and multiply the resulting value by a coefficient. For different types of winding connections, the coefficient is:

- star - 2800;

- triangle - 4800.

The disadvantage of this method is that the data plate is not always preserved on the electric motor. It is impossible to accurately know the power factor and motor power, and therefore the current strength. In addition, factors such as voltage deviations in the network and the magnitude of the load on the motor can affect the current strength.

| Electric motor power, kW | 0,4 | 0,6 | 0,8 | 1,1 | 1,5 | 2,2 |

| Capacitor capacitance C2 in nominal mode, uF | 40 | 60 | 80 | 100 | 150 | 230 |

| Capacitor capacitance C2 in underloaded mode, uF | 25 | 40 | 60 | 80 | 130 | 200 |

| Capacitance of the starting capacitor C1 in nominal mode, uF | 80 | 120 | 160 | 200 | 250 | 300 |

| Capacitor capacitance C1 in underloaded mode, uF | 20 | 35 | 45 | 60 | 80 | 100 |

Therefore, a simplified calculation of the capacitance of working capacitors should be used. Just consider that for every 100 watts of power, 7 microfarads of capacitance is needed.It is more convenient to use several small capacitors connected in parallel, preferably of the same capacity, than one large one. By simply summing up the capacitance of the collected capacitors, you can easily determine and select the optimal value. To begin with, it is better to underestimate the total capacity by ten percent.

If the engine starts easily and has enough power to work, then everything is chosen correctly. If not, you still need to connect capacitors until the engine reaches optimal power.

REFERENCE. When a three-phase asynchronous motor with a squirrel-cage rotor is connected to a single-phase network, at least a third of its power is lost.

It should be remembered that a lot is not always good, and if the optimal capacity of the working capacitors is exceeded, the engine will overheat. Overheating can lead to the burning of the windings and the failure of the electric motor.

IMPORTANT! Capacitors should be connected in parallel.

It is advisable to choose capacitors with an operating voltage of at least 450 volts. The most common are the so-called paper capacitors, with the letter B in the name. Currently, specialized, so-called motor capacitors, such as K78-98, are also being produced.

ATTENTION! It is advisable to choose capacitors for alternating current. The use of others is also possible, but is associated with the complexity of the scheme and possible undesirable consequences.

If the engine is started under load and is difficult, a starting capacitor is also needed. It is switched on parallel to the working one for a short time of starting the electric motor. Its capacity should be equal to or not more than twice the capacity of the worker.

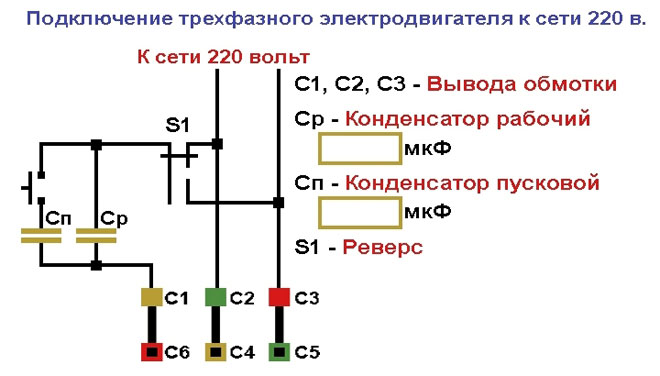

Wiring diagram for a 380 to 220 volt electric motor with a capacitor

Connecting a three-phase motor to a single-phase network is easy and even an amateur electrician can handle it. If there are difficulties, you should contact your friends or acquaintances. There is always a competent electrician nearby.

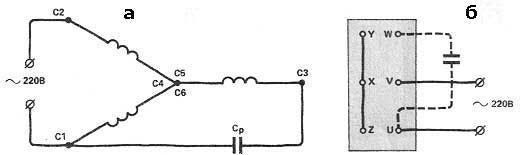

The windings of three-phase motors with an operating voltage of 380 to 220 for operation in a network of three hundred and eighty volts are connected according to the star scheme. This means that the ends of the windings are interconnected, and the beginnings are connected to the network. To be able to operate the electric motor in a single-phase network of 220 volts, it is necessary to switch to the triangle circuit to start its winding. Those. connect the end of the first with the beginning of the second, the end of the second with the beginning of the third and the end of the third with the beginning of the first.

These connections will be the outputs of the motor for connecting to the power supply. Two outputs must be connected through a two-pole switch to zero and phase of the network of 220 volts. Connect the third output through the working capacitors to any of the first two outputs from the engine. You can try to run.

If the launch was successful, the engine runs with acceptable power and does not get very hot, then you can not change anything. It turned out a workable circuit with only working capacitors.

In the case of starting under load or just a hard start of the engine, it can spin up for a long time and not reach acceptable power. Then you will also need to include a starting capacitance in the circuit. Starting capacitors are selected of the same type as the working ones. The same or twice the capacity of workers. And they are connected in parallel. Used only to start the motor.

It is very convenient to use a kind of switch of the AP series for such a start. It is important that it be made with block contacts. In it, when the Start button is pressed, a pair of contacts remains closed until the Stop button is pressed. They are connected to the motor leads and the mains. The third contact is closed only while holding the Start button, and the starting capacitor is connected through it. Switches of this type, only without safety equipment, were often installed on old Soviet centrifugal washing machines.

Wiring diagram for an electric motor without capacitors

There are no really working schemes for connecting a three-phase motor to a 220 volt household network without capacitors. Some inventors propose to connect motors through induction coils or resistors. Allegedly, in this way, a phase shift is created at the required angle and the engine rotates. Others offer thyristor connection schemes. In practice, this does not work, and it is not worth reinventing the wheel. When there is a cheap and proven way to start using capacitors.

A really working option is to connect a three-phase asynchronous motor through a frequency converter. The converter is connected to a household network and produces a three-phase current, moreover, with the possibility of soft start and speed control. But such a miracle costs from about 7,000 rubles with a connected power of only 250 watts. Powerful devices are much more expensive. For such money, you can purchase electrical equipment with the ability to connect to a single-phase circuit. Whether it's a mini lathe, circular, pump or compressor.

How to connect with reverse

It is not difficult to ensure the rotation of the rotor in the opposite direction. A two-position switch must be added to the motor wiring diagram. The middle contact of the switch is connected to one of the contacts of the capacitors, and the outer ones to the motor terminals.

ATTENTION! First you need to select the direction of rotation with the switch, and only then start the engine. The rotation direction switch must not be used while the motor is running.

The considered options for connecting industrial motors to a household network do not present much difficulty in their implementation. It is only important to carefully consider some of the nuances and the equipment, albeit with a slight loss of power, will last a long time and bring benefits.

Similar articles: