Couplings are devices or parts used to connect cables, pipes, steel ropes and other things. With their help, individual elements are combined into one system. Indispensable for the installation of cable systems, plumbing, heating, gas pipelines.

The main requirement is the reliability of the connection, as well as requirements for ease of use and ease of installation.

In addition to reliability, the coupling also provides protection for the structure:

- Due to the limitation of torque, it preserves the structure from breakage during overload.

- Protects against corrosion.

- Protects against moisture penetration due to the tightness of the connection.

Content

Coupling classification

Couplings are of various types. The scope of these devices is so wide that it does not allow them to be unambiguously typified. However, there are several criteria by which this can be done.

By appointment, the following types of couplings can be distinguished:

- Connecting.

- Branch.Used when it is necessary to make a branch when installing cable lines.

- Transitional.

- Locking. They are used in high voltage electrical networks (110 kV).

- End.

By execution there are:

- Single-phase.

- Three-phase. Designed for use when working with multicore cables.

According to the material of manufacture, there are such types of couplings as:

- Cast iron.

- Lead. Lead sleeves connect metal cores of cables, in which the sheath is made of aluminum or lead, with a voltage of 6-10 kV. They are quite heavy.

- Brass.

- Epoxy. Made from epoxy resin. Most often, asbestos or metal casing is used to protect them. They are used to connect cable conductors laid in tunnels, trenches or mines. They are used, like lead, at a voltage of 6-10 kV.

- Shrink. A heat shrink sleeve is used as the most common way to isolate the junction. Installation based on heat-shrinkable materials greatly facilitates the technology of connecting cables and saves time for this work.

By type of cable insulation are:

- impregnated.

- Paper.

- Plastic.

- Rubber.

Couplings

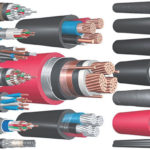

The cable network can stretch for various distances, but the integrity of the system must be ensured. The connecting elements are connected in series and unite the individual parts of the cable line together. This causes the couplings to transmit electricity, like a power cable, with minimal voltage loss and with the preservation of all electrical characteristics.

Couplings are selected depending on the technical parameters of the cable.To choose the right connector, you need to consider:

- the number of wires in the cable;

- the material from which the cable cores are made, as well as their diameter;

- cable insulation;

- maximum voltage in the network;

- method of protection from external influences.

To correctly install the connecting element on the cable, you need to cut the ends, remove all the cable insulation, then sequentially prepare each individual layer for installation. On each side, it is necessary to completely remove the insulation for half the length of the connector, into which both ends of the wire are then inserted. Once you have entered all the cores on both sides, the coupling must be firmly clamped with fasteners.

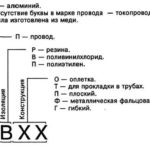

All cables have their own designation. Due to the wide selection of cables, there are also varieties of connecting elements. Which coupling to use, what it consists of, its technical parameters - all this can be found in the marking of cable couplings.

For example, there is a cable sleeve brand 1STp-3x150-240S. In this case, the marking is deciphered as follows:

- 1 - used in electrical networks with voltage up to 1000 V.

- C - connecting.

- Tp - has a thermoplastic insulating layer.

- 3 - number of wires.

- 150-240 - minimum and maximum cross-sectional area.

- C - indicates the presence of additional fasteners.

Sometimes the marking may indicate the feature of the product:

- R - repair;

- O - cable with one core;

- B - armored.

The letter indicating the feature is affixed after the indication "Tp".

Transition Couplings

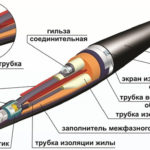

The transition sleeve allows you to connect cables of different types or cables with different conductor diameters.The design of one of these connectors, when combining a three-core cable with three single-core cables, evenly distributes the tension in the cut area.

Hot melt adhesive is applied to the inner surface of the protective casing. This ensures the tightness of the connection. The cores are connected by a bolt method, or sleeves are used for crimping.

Products of this type have their own marking. She is simple enough. Name 3 SPTp-10 (70-120) M can be deciphered as follows:

- 3 - number of wires;

- C - connecting;

- P - transitional;

- T - heat-shrinkable;

- p - with a glove;

- 10 - maximum voltage of the network, kV;

- 70-120 - minimum and maximum cross-section;

- M - there is a connector in the kit.

Mount products of this type in the following sequence:

- Cable preparation and cutting. The conductors are trimmed, the insulating layers are removed one by one.

- Installation of insulating tubes. The tubes are put on the cores and are located at the place where the cable is cut.

- Mounting gloves. The cores of the cable come together as tightly as possible.

- Sleeves and cuffs are installed. The cores are bent until they coincide horizontally with each other. Cuffs are put on, which are located in the middle of the docking site.

- Sealing of the interfacial cavity. The space inside is filled with filler.

- The casing is located in the center of the structure.

- An aluminum tape is wound on the casing.

- Grounding. Both ends of the flexible copper wire are on a surface armored with aluminum tape.

- A protective outer casing is put on the middle of the coupling.

End couplings

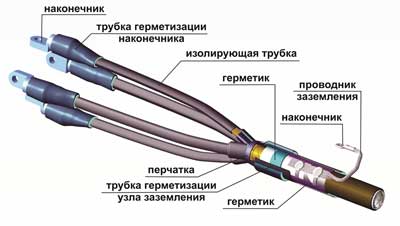

Terminations close the electrical cable circuit. Feature: the presence in the design of the compound.It is a thermoset, thermoplastic polymer resin. Such a coupling resembles a cap and is a simple plug.

In addition to the compound, this type of connector has in its design:

- heat shrink insulators;

- sealant in the form of a tape;

- tip with breakable bolts or designed for crimping;

- ground wire;

- a plate that equalizes the electric field;

- heat-shrinkable tubing for insulation;

- heat-shrinkable cuff to perform a shielding function.

The purpose of such a device is to separate and connect the metal cores of the cable to devices such as a transformer or electric motor. They connect the power cable and distribution equipment.

Connectors of this type are widely represented on the market. In this regard, you should carefully select the model of this kind of device. In doing so, several criteria must be followed:

- the number of cores in the conductor;

- the highest voltage in the network;

- cross section of conductors;

- type of cable insulation;

- operating conditions.

The designation of the end sleeves is similar to the marking of the connecting ones. The only difference is the addition of a few letters. 1 KV (N) tp-3x150-240 N. Here, the additional letters K, V (N) at the beginning and N at the end indicate the following:

- K - terminal;

- В(Н) - internal (external) installation;

- H - has a set of mechanical bolt tip.

Common installation errors

Inexperienced workers often make mistakes when installing couplings. The most common of them are:

- Surface contamination. Connectors are mounted outdoors, in trenches, tunnels, etc.This causes difficulties in organizing the cleanliness of the workplace. But when assembling the coupling elements, it is necessary to monitor the cleanliness and timely wipe the elements from contamination.

- Violation of installation technology. The dimensions of the cores and sleeves must necessarily comply with the requirements. Otherwise, burrs and "ears" may appear. They must be identified in the course of work and immediately smoothed out.

- Violation of tightness. On the upper surfaces, additional windings with sealant are used to seal the joints. After heat treatment, the adhesive should protrude beyond the edge of the gap. Thus, it blocks the access of harmful substances inside the joints. If the glue does not protrude, then the requirements of the technology are not met. Also, before the final laying of the cable into the ground, an external inspection should be carried out for cuts and microcracks. There shouldn't be any.

- Air voids. All spaces between coupling elements must be filled with sealant. The appearance of air cavities should not be allowed.

The installation of the coupling must be carried out strictly according to the rules, in compliance with all norms and recommendations. It is best to entrust this work to highly qualified and experienced professionals.

Similar articles: