The connection of wires affects the safety and reliability of electrical wiring. It is carried out in different ways, using connecting devices, devices, depending on the characteristics of the wires.

Content

- 1 Why use a junction box?

- 2 Ways of connecting conductors

- 2.1 Use of terminal blocks

- 2.2 Spring terminals

- 2.3 Installing PPE caps

- 2.4 Crimping with special sleeves

- 2.5 Soldering or welding

- 2.6 Twisting and insulation

- 2.7 Clamp "nut"

- 2.8 Bolt use

- 2.9 Connecting multiple wires

- 2.10 Connection of conductors of different sections

- 2.11 Combining stranded and solid products

Why use a junction box?

Junction (otherwise junction, branching) box is a type of junction box in which wires are switched, electrical connections are made. It can be round, rectangular, square in shape, plastic, steel, fiberglass, aluminum in material.

The device is a container, the purpose of which, with any method of connecting wires in a junction box, is to hide the branching of the mains. In addition, it allows you to effectively redistribute the load on the network, prevent short circuits in them.

There are many ways to connect wires in a junction box. The simplest - twisting - used to be a priority. Today it is considered dangerous, unreliable. It was replaced by special connecting devices, devices designed for various characteristics of the connected cables.

Ways of connecting conductors

Correctly connecting the wires to each other means ensuring the reliability and safety of the electrical network. There are many types of wire connections. You can use long-used ones - twisting, soldering, bolting. It is easier and faster to do the job by using a cable connector - a special device that allows you to reliably connect cables of different diameters, single- and multi-core, from various materials,

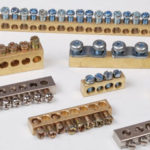

Use of terminal blocks

Pads for connecting wires are a type of electrical installation products. They are called terminal blocks, terminals, terminal blocks, terminal blocks, KB, terminal clamps, terminal connectors. Contain 2 metal contacts or more. The latter have nodes in which cables are fixed, and are placed inside a dielectric housing, often sealed (filled with gel).

There are many types of terminal connectors. They are distinguished:

- according to the method of installation: screw, detachable, pressure, barrier, through;

- one-, two- and multi-row;

- for one-two-, three-row and multi-level cables;

- angular and straight;

- for single and stranded, flexible conductors;

- according to the method of clamping the wire: screw, spring, knife, end.

The cable connector is inexpensive. Contains a clamping cage enclosed in a plastic housing. For the manufacture of the clamp, phosphor bronze, stainless steel are used; body - polyamide; screws - brass, nickel-plated or galvanized steel.

Connect the electrical wires to the device in the following order:

- remove the insulation from the ends of the cables;

- 1 conductor is inserted into the clamping cage, fixed, depending on the type of terminal block, with a screw, spring, knife;

- to form a network, 1 or more conductors are installed in it and clamped in the same way.

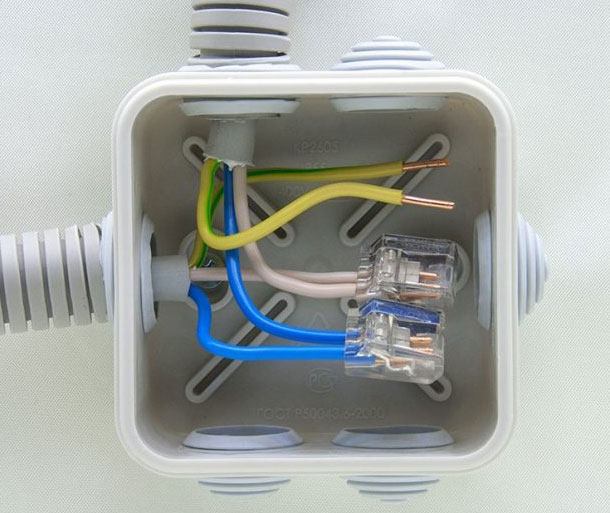

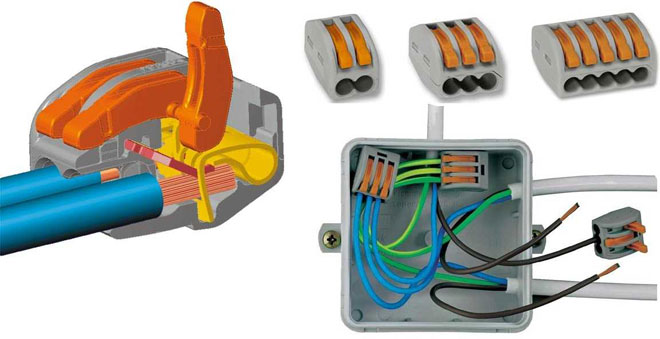

Spring terminals

These are terminal blocks in which the cables are fixed with a plate (bus) under the action of a spring force. Types of connection of electrical wires using such devices:

- fast, allowing you to save up to 80% of the time of an electrician-installer;

- do not require the use of a screwdriver - the conductor is fixed by the terminal mechanism after insertion;

- provide a constant contact force on the conductor, do not deform it;

- allow you to connect cables of different material and cross section.

How to connect two wires:

- remove the insulation from the conductors (1 cm);

- raise the lever on the clip body;

- insert the end of the cable into the connector;

- lower the lever into place.

Terminal blocks without levers are available. In them, the wire is automatically clamped after being inserted into the groove of the connector. Most are gel-filled, making the devices hermetic connectors offering the highest level of protection.

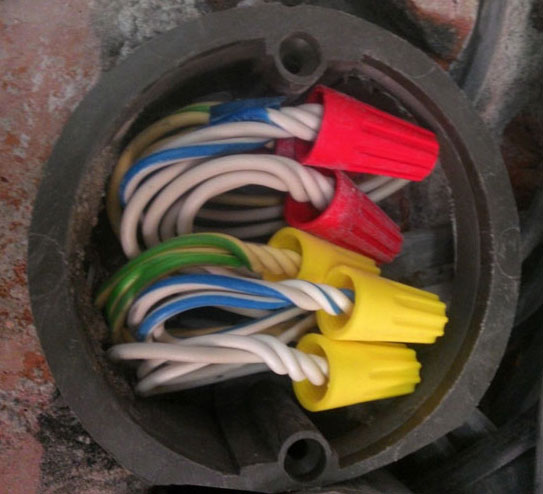

Installing PPE caps

This type of cable connector is a cone cap made of non-combustible plastic. Inside it may contain a conical metal spring or a bushing with a large thread. It is used for a better twisted connection, protects it, providing reliable insulation.

Caps with a spring are wound onto a twist made in advance. The spring expands due to the pressure of the conductors, providing additional compression of the junction.

Threaded caps can be screwed onto cable ends without a twister. After making 2-3 turns, a reliable twist connection is obtained inside the PPE cap.

Crimping with special sleeves

The electrical wire connector represents tubular elements - sleeves. Suitable for networks with medium and high current. Provides good electrical contact, the strength of the connection is the highest among the methods used. In the minuses of the method - the conductor cannot be further disconnected.

Produce the connection of wires without soldering in this order:

- Remove the insulation from the cable ends. Use a knife, a special tool.

- The ends are inserted inside a tube of a similar material. The placement must be tight - additional sealing, if necessary, is done by inserting pieces of bare cable into the tube.

- The sleeve is compressed using special press tongs. They do this near both of its ends, and in different directions. If the cross section of the sleeves is more than 120 mm², the cable connector is crimped with a tool that has a hydraulic drive.

The connection of wires obtained with the help of special crimping sleeves must be insulated.

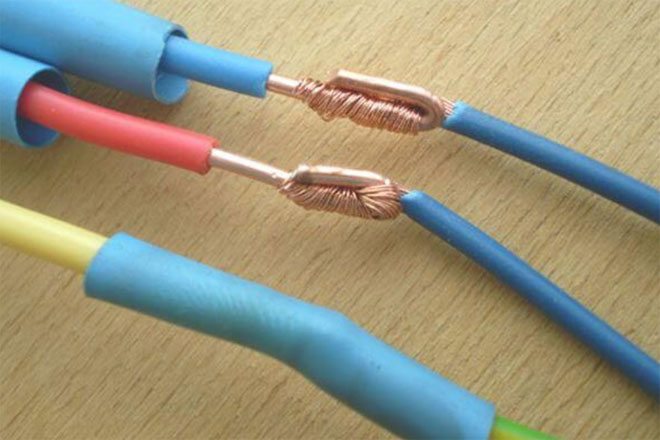

Soldering or welding

Reliable connection of wires in the electrical network is ensured by their welding. As a result, a solid conductor is formed that does not oxidize, has a minimum resistance, and eliminates a short circuit.

How to connect wires by welding:

- insulation is removed from the conductors, the wires are cleaned with sandpaper to a shine;

- connect the wires with a twist;

- flux is poured into the recess of the carbon electrode;

- turn on the welding machine (24 V, minimum power - 1 kW), press the electrode to the welding site, hold until a contact point in the form of a ball is formed;

- the flux is cleaned from the place of welding, the contact point is varnished;

- isolate the connection.

Soldering electrical connections gives the same results. Carrying it out is similar to welding. Difference:

- in the use of solder, which is melted with a soldering iron;

- mandatory filling with solder strands inside.

Soldering connects the cables securely, but the method is not effective:

- if the cables are exposed to heat;

- when connections are subjected to mechanical stress.

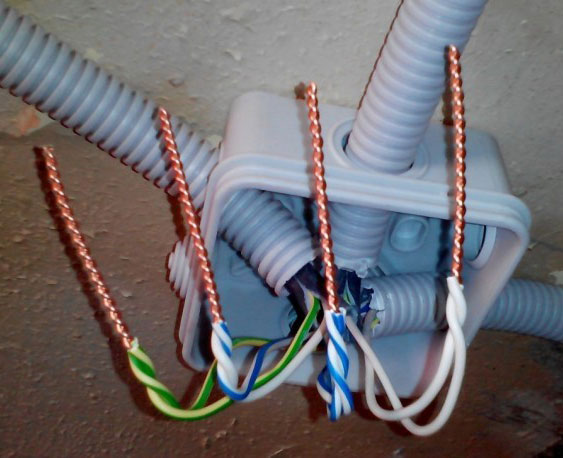

Twisting and insulation

The twisting method is the simplest of the conductor connections. It is used when connecting aluminum wires to each other or others, but from the same material. It is considered unreliable, therefore it is prohibited when installing electrical networks. When deciding what is better for forming a network, Wago terminals or twisting, they prefer the first option.

How to twist the wires correctly:

- remove the insulation at the ends of the conductors with a knife;

- grab the ends with pliers and, holding the cables with the other hand, make 3-5 twisting movements;

- twists are covered with insulation.

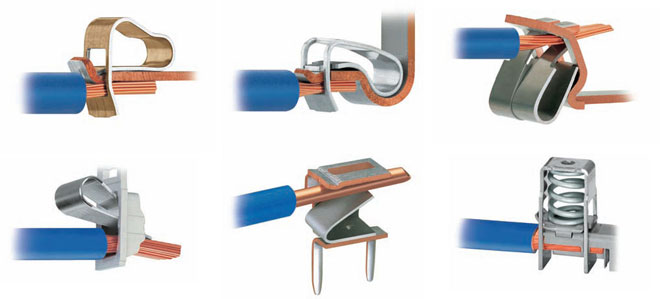

Clamp "nut"

Wire clamps with this name have a cuboid insulated body made of polycarbonate. It contains a metal core, which includes 2 dies with grooves for the wire and an intermediate plate. The latter are compressed together by 4 bolts.

Clips for connection of wires "nut" provide reliable connection of cables. They are produced for different sizes of the latter - the marking is applied to the surface of the dies.

Bolt use

The bolted connection of wires is reliable, but has large dimensions, which makes it impossible to place a large number of them in modern junction boxes. It is done with a bolt, washer and nut. The order is as follows:

- remove the insulation at the ends of the cables to be connected, form rings on these sections;

- a metal washer is put on the bolt body;

- place on it a ring of one of the conductors;

- closed with a steel washer;

- put on the next cable with a ring;

- install 1 more washer;

- seal everything with a nut and close it with insulation.

Connecting multiple wires

This can be done by twisting, but on the condition that all cables are made of the same metal. Then it is better to close their association with a PPE cap, solder, which will increase its reliability and safety.

For such situations, a cable connector in the form of a terminal block is suitable, provided for single-, double- and multi-row connections. You can combine several conductors with 1 bolt.

Connection of conductors of different sections

The best for this option are terminal blocks designed to connect cables that differ in cross-sectional size. Suitable twisting with soldering, bolt.

Combining stranded and solid products

You can combine multi- and single-core cables by soldering, bolting. But, choosing which is better - twisting or terminal block, you need to give preference to the latter. There are types of terminal blocks that are designed for such situations, regardless of the material of the cables.

Similar articles: