Aluminum wiring is now rarely used for laying electrical networks in houses and apartments. It must be replaced during repair work. However, it also happens that the work is carried out partially. In this case, the problem arises: how to connect copper and aluminum wires.

Content

What problems can arise when joining aluminum and copper

When answering the question whether it is possible to connect copper to aluminum, it must be recalled that the following problems arise when twisting copper and aluminum wires:

- Decreased electrical conductivity. Aluminum is an active metal; under normal conditions, it is covered with an oxide film that has low conductive qualities. Copper does not have this property.

- Weakening of contacts. Due to the formation of plaque, contacts become worse.Such a film does not form on copper conductors, therefore metals are considered electrochemically incompatible.

- Fire hazard. When wondering how to connect an aluminum wire to a copper one, they remember that electrical contact occurs between the oxide deposits formed on the wires. Over time, metals begin to heat up, which leads to a fire.

- Electrolysis. If the system is operated in conditions of high humidity, the connection begins to break down, becoming a source of fire. First of all, corrosion covers the aluminum parts of the wiring. With regular heating and cooling, cracks appear in the insulating braid, the connection is covered with an oxide or salt layer, which accelerates destruction.

- The formation of conductive soot. Contact in this case is broken, a fire starts in the house. When operating electrical wiring in a dry room, this process lasts for years. With high humidity, ignition occurs after a few months.

Ways to connect different wires

How to connect copper and aluminum wires:

- using another metal;

- preventing the appearance of harmful oxide plaque.

In the second case, special compounds are used that can protect the metal from the effects of moisture and oxidation. Pastes prevent the destruction of the connection. Another way to protect against fire is tinning. Tinned stranded cable can be twisted with aluminum single core. For connection, special devices are also used:

- Clamps. Used to connect to an aluminum riser in the driveway. Branch clamps have punctures or lack them.The device is equipped with an intermediate plate that prevents contact between two metals. Some clips are treated with paste. Sometimes the use of special formulations is not required.

- Spring and self-clamping terminal blocks. It is possible to dock and splice wires from different metals using terminals that have sockets and partition plates that separate aluminum conductors from copper ones.

- Bolts. When making a bolted connection between the wires, a washer made of stainless or galvanized steel is laid.

Terminal blocks

Terminal blocks are:

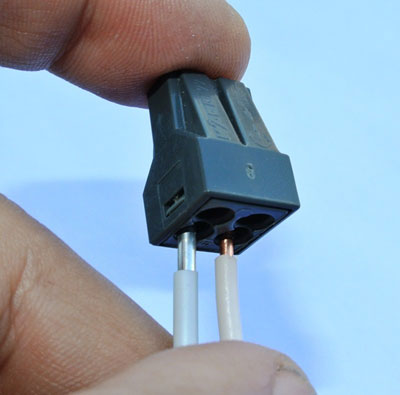

- Disposable. They are used when connecting wires in junction boxes and installing chandeliers. To insert the cores into the hole of the device, efforts must be made. Even more difficult is the extraction of the cable from the block.

- Reusable. For fixing there is a lever, thanks to which the cable can be inserted and removed several times. Blocks of this type are used when connecting stranded wires from different metals. If the work is not done correctly, the connection can be redone.

Installation is carried out as follows:

- the cable is cleared of the insulating coating;

- the veins are stripped to a metallic sheen;

- on the reusable terminal block, a lever rises;

- the cleaned part of the wire is inserted into the hole of the block until it stops;

- the lever returns to its original position.

Crimping

In this case, tubular sleeves are used, which reliably and safely fasten the wiring elements. To connect the cables, you will need a press, mechanical, hydraulic or electric pliers. Installation includes:

- sleeve selection and tool adjustment;

- cleaning the wires from the braid;

- stripping the cores (sandpaper is used for this);

- applying a quartz-vaseline composition;

- inserting the ends of the cables into the rivet;

- crimping (when using a simple tool, several crimps are performed at a short distance, when using a good tool, crimping is performed once);

- connection isolation.

The wires are inserted into the sleeve from opposite sides so that the joint is located in the middle of the connector. Cores can be inserted from one side. The connection of cables with a sleeve is sometimes replaced by the use of "nut" clamps, however, the latter are less reliable. The rivet will loosen over time, increasing the risk of fire.

Bolted connection

Subject to the installation rules, the method provides a durable fastening. To complete the work, you will need 2 simple washers, 1 spring washer, nut and bolt. The wires are cleaned of insulating material. A spring washer is put on a bolt, which is inserted into a simple washer. The end of the aluminum cable is folded into a ring, which is thrown onto the bolt. After that, put on a simple washer and screw on the nut. The stranded wire is coated with solder before starting work.

Soldering

This is a reliable and technologically advanced method that provides a high-quality connection. Before soldering, the cores are cleaned of braid and oxide film. If necessary, the cables are tinned, loosely twisted, treated with flux and soldered. It is impossible to connect aluminum and copper wire using acid flux. The composition destroys metals, reducing the fastening strength. The junction is isolated in the usual way.

Features of the connection lived on the street

When performing work on the street, take into account that the wires will be affected by precipitation, high and low temperatures, and wind.Therefore, when performing installation work, sealed structures are used that are insensitive to ultraviolet radiation and high humidity. When connecting wires on roofs, facades and poles, piercing clamps are used.

Similar articles: