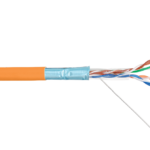

The insulated pin sleeve tip, or NShVI, is made in the form of a sleeve made of special copper with electrolytic properties and a plastic ring. They are used to create standard connections at the ends of cables. The terminals obtained in this way guarantee high-quality and durable contact, avoid deformation and damage to the wires when using screw fasteners.

They are used for stranded copper wires with a cross section of up to 35 mm². To improve the current conductivity index, the sleeves are galvanized. The use of such products will save time and effort when creating and maintaining electrical connections.

Purpose

Sleeve lugs allow you to assemble multi-wire contacts into one strong core. Otherwise, a wire with a large number of cores will not work securely. The wire will be pinched, broken off, reducing the nominal cross section of the wire and worsening the current conductivity.As soon as such a bundle is clamped in the terminal, the strands will disintegrate throughout the connector, losing the connection's bandwidth.

Before the advent of NShVI, such a problem was solved by tinning the ends. This made it possible to combine all the cores into one solid bundle. But this method took a lot of time and effort.

The use of NShVI will provide a high-quality connection when crimping the wire. Compressible sleeve tip evenly distributes the load on the entire core. There are copper sleeves of various diameters, with a corresponding color marking. Crimping will not cause difficulties if you have a special tool.

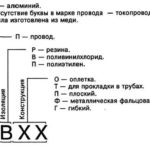

Marking

There are many different NSHVI, differing in design and alloys. Labeling is designed to help in the selection of the optimal product.

The abbreviation NShVI means that this is a pin sleeve insulated tip. For ease of use, plastic flanges on copper bushings are made in various colors. Each color has its own bushing diameter.

The numbers indicated in the marking indicate the required section and length of the sleeve. If it is possible to fasten two copper conductors, the number (2) is put.

So marking NShVI (2) 1.5x8 means that the sleeve is made of tinned, copper tube for two cables with a cross section of 1.5 mm². The length of the contact part is 8 mm.

How the tip of the pin NShVI works

NSHVI is assembled from two elements:

- Conductive tube made of tin-plated, electrolytic copper alloy.

- Insulating polyamide flange.

For such products, a special copper alloy is used.This eliminates the possibility of damage to the conductor in the places of fixation using screw fastening. NSHVI are made with a cross section of up to 150 mm². The material used is subjected to galvanic tinning. One of the ends of the tube is flared for ease of insertion of the wire.

The selection of NSHVI is carried out according to special tables. They also indicate the color of the cuff and the tool necessary for crimping.

Bushings are available for crimping one and two contacts. Using the dual design, 2 stranded wires can be crimped into one bundle. They are used in the event that it is necessary to bring two wires into one socket.

The visual difference is that the plastic flange is wider for two wires.

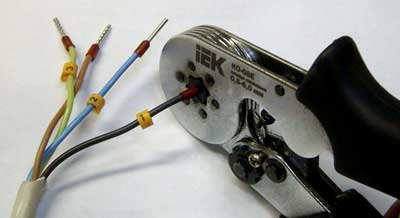

How to crimp sleeve lugs NShVI

The crimped tip is not a removable connection. In case of unsuccessful crimping or if it becomes necessary to change the tip, it is cut off. To compress the sleeve, special press tongs are used. The kit includes nozzles for different sections of bushings.

There are various modifications of press tongs for crimping end sleeves, models of which can perform one or more functions. According to the type of construction, they are divided as follows:

- Universal press tongs are the most common and easy to use. They are used to remove insulation from wires and crimp sleeves. Such pliers, in addition to crimping NShVI, can also be used to work with other types of tips.

- Press tongs with pressure control device. These pliers are equipped with a special device that regulates the degree of compression of the wires and prevents damage to the sleeve.

- Press tongs with articulated mechanism.This design allows you to increase the clamping force to facilitate the process of manual crimping.

- Ratchet pliers. The design feature of such pliers is that involuntary unclenching of the tool and damage to the sleeve are excluded.

Before pressing, it is necessary to carry out a number of preparatory measures:

- Having determined how long the tube is required, the insulation is cut off from the surface of the wire. The length of the stripped cable must match the length of the sleeve. To do this, use universal press tongs, a sharp knife or a specialized device - a stripper.

- The sleeve has a flare on the inside. This facilitates the process of inserting the wire. But to avoid bending individual wires, the core is twisted a little beforehand.

- The bushing diameter is selected according to the cable section. The twist should enter freely, but should not hang out.

- When preparing press tongs, you should pay attention to the color marking applied to the matrix. It matches the colors on the tips. Manufacturers strive to match the color designation of diameters between dies and bushings to facilitate the installation process.

When crimping the tip, the cable should be taken with a small margin. If for some reason the crimping did not work out, then the tip is cut off and the procedure is repeated again.

For high-quality crimping, there are conditions:

- The stripped end of the wire must not stick out of the sleeve above the plastic insulating collar of the ferrule. The end should be flush with the edge of the sleeve.

- After making sure that the colors on the sleeve and the matrix match, squeeze the handles of the tongs until the ratchet is activated. He must block the tool, preventing it from unclenching.After checking, the ratchet is released.

- When using pliers without a ratchet, the degree of compression is controlled by a slight movement of the wires. The cores must be tightly crimped and must not move.

- After completing the procedure, it is recommended, while holding the wire, to pull the tip to make sure the contact is reliable.

There are devices with double-circuit crimping. They differ in that they squeeze not only the copper sleeve, but also the plastic insulator. The matrix of such mites consists of two nests of different diameters. Before crimping, make sure that the diameters match and that the sleeve with the flange is in place.

The double insulated ferrule crimp has some differences. Such a connection is used when several wires must be clamped into one terminal. In this case, the use of single tips creates difficulties in connection. That's why double tips are used.

The process consists in the fact that several pre-prepared wires are inserted into the wide flange and crimped with a crimper. This device is also suitable for crimping single ferrules.

Crimper - for crimping end sleeves, models are self-adjusting and with interchangeable dies of different sizes. The self-adjusting device is equipped with four movable cams that compress the sleeve. Thanks to this design, no replacement nozzles are required. The diameter of suitable bushings is indicated on the tool itself.

In the event that it is necessary to crimp several wires together, but there is no double sleeve, use lugs with a large cross section so that two wires enter inside.

Correspondence of the sizes of sleeve lugs and wire section are provided by the manufacturer.They need to be strictly observed. This will prevent damage to the cable, eliminate the need for re-crimping and ensure proper operation throughout its entire service life. A specialized tool will ensure the reliability of the work done, facilitate the installation process.

Similar articles: