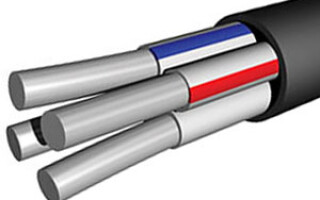

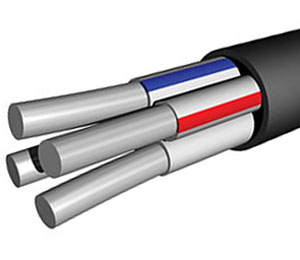

AVVG is a flexible conductor based on aluminum conductors. Core insulation is provided by polyvinyl chloride material. Manufacturers placed this entire group in a PVC sheath.

The high level of productivity, as well as the low cost of the product, made it the most suitable for arranging not only industrial and warehouse premises, but also the residential sector.

The AVVG cable has the following decoding:

- A - only aluminum conductors are used;

- B - the sheath of the cores is made of polyvinyl chloride;

- B - PVC outer sheath (standard);

- D - no protective coating of the shell, the cable is bare.

Additional cable marking indicates the following:

- T - wire can be used in tropical conditions;

- NG - does not support combustion;

- Z - laying in the ground is allowed with low corrosive activity;

- OZH - the core consists of one wire;

- P - cores have a flat arrangement.

Specifications of AVVG cable

The wire is used to transmit electricity at 600 and 1000 V. The frequency of the alternating current is 50 Hz. Permissible temperature parameters vary between -50°С ... +50°С. The conductor must not be heated above +70°C. During an emergency situation, it is able to withstand + 80 ° C.

When installing in conditions of -15 ° C and below, it is necessary to preheat the wire. When laying, it is important to observe the correct bends when cornering. For a single-core cable, a bend of 10 diameters is allowed, and a stranded cable can be bent at an angle of 7.5 diameters. If all conditions are met, the AVVG cable will last 30 years.

Design

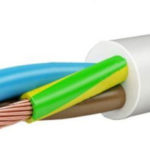

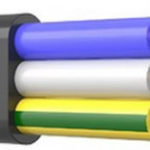

Power cable AVVG consists of cores made of soft aluminum. Due to this, it has flexible properties. It is convenient for installation. However, failure to follow the installation rules can make it fragile. The cores can be sector and round, and also consist of one or more wires. In total, the AVVG cable device involves the use of up to 6 wires. All types of section correspond to GOST. In addition, the cores can have a different cross section, at zero the smallest.

The insulation also complies with GOST and has a standard marking. Grounding is green or yellow, and zero is marked in blue.

Application area

AVVG cable has found its application in various fields and operating conditions:

- local power grids;

- enterprises;

- distribution substations;

- residential buildings;

- industrial premises.

The wire has no armor, so its laying implies the absence of compression and mechanical impact. In addition, it is subject to stretching, which can lead to damage to the insulation.This means that strong sagging should not be allowed.

For safe laying in the ground, LSZ tape is used. The conductor itself must be marked "Z". In this case, plastic compound is used, which fills the space between the cores and makes their arrangement more dense.

Laying is carried out on a sand cushion inside the trench, then everything is covered with sand. The layer should be about 20 cm. It is important not to stress the conductor. It is necessary to lay a signal tape along the entire length, and in places where a load on the ground is expected, the wire must be placed in a metal pipe.

In places where fire safety is given special attention, use a cable marked "NG".

For domestic purposes, it is appropriate to use a conductor with cores from 2.5 to 6 mm². The presence of internal and external insulation allows for outdoor installation without a cable channel. Internal laying is carried out using corrugations.

The cable is suitable for arranging basements, garages and yard buildings with open wiring. Laminate is not exposed to ultraviolet radiation, it is not affected by air humidity and it does not rot. Nevertheless, the conductor is not suitable for equipping baths or saunas, since the air temperature exceeds +50 ° C.

Similar articles: