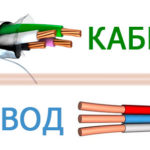

Single-core and stranded wire has its own structure, purpose and scope. Requirements have been developed for each type, nominal parameters have been established. The difference between a single-core and multi-core cable is in the physical properties, method of installation and operation.

Content

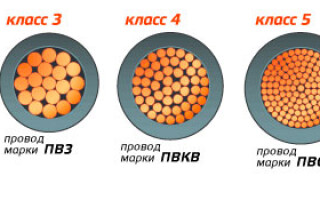

Flexibility class

To characterize a single-core and stranded wire, you need to understand their technical characteristics. Structural parameters are regulated by regulatory documents. The established state standard GOST 22483-2012 defines the parameters that allow them to be classified by type and category.

When characterizing the resistance of a cable to deformation, the flexibility parameter is used. Based on the indicators, flexibility classes are distinguished. The mains used in industrial production belong to class 1.

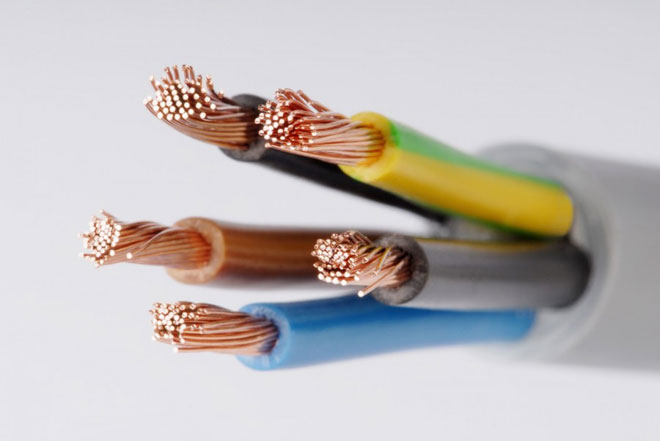

The second class is characterized by greater flexibility, to achieve which several wires are used. For grades 3, 4, 5 and 6, the criterion is the number of threads and their diameter. The state standard indicates the maximum diameter for each of them.

Wire brand PV-1 belongs to class 1. It has one conductive fiber covered with a layer of insulating material. KOG brand cable is a particularly flexible wire, belongs to class 6, consists of thin threads.

To understand the difference between a single-core and a multi-core cable, you can consider the technical parameters using the example of materials with a cross section of 1 mm² of classes 3 and 5. Class 3 wire consists of a specified number of fibers with a diameter not exceeding the norm.

For 5 - this figure is 0.21 mm, respectively, it will contain more individual metal threads. Their number should be higher than 7 and different from the indicator that characterizes the 2nd group.

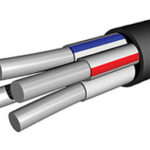

Fibers are made from materials that conduct electricity and heat. Aluminum is not used in material with a nominal cross section up to 1 mm². Annealed copper fibers with and without metal coating are used in all classes of utility materials.

Aluminum cables, which have a cross section of 16 mm² or more, are also characterized by flexibility, they can use several fibers.

Single core cable

Materials for laying communications with one monolithic metal fiber are of the installation type; they are mounted permanently without the subsequent possibility of movement.The cable has high rigidity, when using it, the wiring in the shield looks aesthetically pleasing and provides convenience when servicing automation.

The advantage of a single-core cable is its low price. As a conductive element, it has one core with a cross section of the diameter established by the standards. It is designed for installation of hidden wiring in the wall.

Using a single-core cable, switches and sockets are connected. A twist of several fibers is easily crimped with terminals or welded. With large cross sections, a cable with 1 fiber has a higher mechanical strength. The complexity of laying hard material in a plastic box is different.

stranded cable

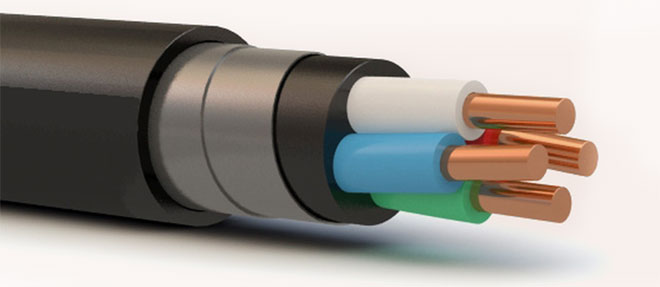

In this type of material for laying communications, the conductive element consists of several fibers intertwined with each other. The established standards allow the interweaving of a non-conductive nylon thread to increase elasticity.

To determine which cord to use: soft or rigid, it is important to pay attention to the flexibility index and the allowable bend radius. Such material is convenient to mount, it can be moved if necessary.

For portable installations, a flexible wire (cord) can be used. The installation of stranded wires allows the use of brass lugs for switching without the use of additional tools.

Tips are used for connection with screw terminals after pressing. The use of these fasteners eliminates the benefits of solid wire for these types of connections.

A multi-core cable is practical to use when installing a temporary electrical installation. This type of communication material is easier to fit in the box, which saves time during installation.

In sound or signal cables, electric current is displaced to the surface of the conductors. This means that the current density is lower in the middle of the cross section. The advantage of wires with more fibers is that they solve the problem of skin effect, heat up less and reduce transport losses.

Scope of application

Each type of wire has its purpose, and the properties allow you to determine which wire is better: stranded or solid with one fiber. Stationary wiring of power cables in residential premises, industrial facilities is installed using single-wire conductors.

On electrified railways, communications are laid using such wires. Their service life is designed for a long time. Non-stationary wiring is installed in places with increased vibration, where multiple bends are required.

These communications require stranded conductors. Therefore, household and industrial extension cords that transmit power from the source to the consumer are made from a material with a large number of fibers.

In cars, a single-core wire occupies a smaller part of the wiring. Most often, a flexible cable is used during installation.

Choose between solid and stranded wire

To determine which is better: stranded wire or solid wire, it is important to evaluate the advantages of each type, taking into account the resistance to transmission of electric current.

The main advantage of single-core cables is the low resistance index, calculated for 1000 running meters.For example, this parameter for a copper conductor with a diameter of 1 mm should be 18.1 ohms. A class 5 wire may have a resistance higher by 1.4 ohms, which is within the allowable error.

This deviation is explained by the fact that with a decrease in the cross-sectional diameter of a single fiber, the resistance increases. Even when connecting many single fibers into a single unit, a total deviation is observed.

The main differences between a single-core cable and a multi-core cable are in the method and ease of installation. The Electrical Installation Rules Manual (PUE) provides for the following types of connections:

- screw;

- clamping;

- welding;

- pressing;

- soldered.

It is possible to connect a single-wire and multi-wire cable using various materials, the choice of which depends on the diameter and number of metal fibers. For example, it is better to make a connection using screw terminals for a solid wire.

In this case, the screws will not pinch the conductor, and the individual fibers will be firmly fixed at the contact connection. It is easier to connect a wire with 1 fiber, but this does not mean that you cannot weld a multi-core cable.

It is important to consider: high-class conductors can be damaged during welding, which will negatively affect the quality of the connection. Pressing is carried out using a special tool. This method can be used for any type of wire. It is allowed to solder materials with a small cross section of fibers.

To determine which copper wire is better: stranded or solid - when laying communications, you need to assess the availability of space for installation.If the cable requires a lot of bending during installation, it is easier to use a material with a large number of fibers.

Similar articles: