According to the technical requirements of the PUE, electrical wire connections are made only using special blocks or terminal connections. The main condition is the reliability and strength of the connections, on which fire safety and trouble-free operation of the wiring directly depend. Professional electricians use German Wago terminal blocks, which feature a convenient design and connections due to the constant action of the built-in spring.

Content

What are Vago terminal blocks for?

Unlike similar products from other manufacturers, Wago clamps have a wide scope, since they can be used when laying electrical wiring both at home and at work. A successful design solution makes them safe to operate even under conditions of high voltage and strong electric current.The Wago terminal block body is made of a special modified polymer that is not affected by moisture and is resistant to temperature extremes. At the same time, Wago terminals are suitable for wires of various modifications.

With the help of Wago connecting terminals, copper and aluminum cables of different cross-sections and types (solid, stranded) can be joined, while ensuring high reliability of installation. They are used when laying external and hidden wiring, inside junction boxes, in places where, due to technological complexity, it is impossible to solder. To connect wires using Wago terminal blocks, it is enough to insert the wire into the hole until it stops and snap it into place.

Advantages and disadvantages

German Wago terminals have significant advantages, the main of which are the following:

- a clear fixation with a spring, excluding accidental disconnection;

- ease of installation, even in hard-to-reach places and in conditions of lack of lighting;

- compact dimensions that make it easy to hide the terminal in the junction box;

- high impact resistance, resistance to vibration effects;

- no need for special maintenance;

- easy disconnect if necessary.

Modern Wago connectors also have such a property as compensation for thermal expansion, so that the connection remains intact even with strong changes in temperature and humidity. Among the shortcomings of reusable terminal blocks, one can single out the high cost, however, given the high quality and reliability of the connections, the price is fully justified.

Specifications

All Wago terminals, regardless of modification and size, are made of electrolytic copper alloy with a special tinning, in the design of which there is a chromium-nickel spring. The case is dielectric, consisting of an alloy of polyamide and polycarbonate, which has a high resistance to current. The manufacturer produces dozens of modifications of such products, defined by series 222-773, where a Vag clamp of one of the following types is used:

- fit-clamp: uses an IDC mortise contact that allows you to connect cables without first removing the insulation;

- cage clamp: here the steel spring is separate from the conductive type tinned copper bar, allowing both solid and stranded wires to be connected.

There are both reusable and disposable Vago models, so the master can easily choose the option that suits him best.

Types of terminal blocks

The range of Wago terminals produced by the manufacturer can be divided into the following types:

- WAGO Compact (221): a universal type terminal connection, which is excellent for reusable clamping of wires of different sections and types (solid, stranded) made of copper and aluminum. It is used when there is not enough free space in the junction box, since the terminal has a compact size.

- Push Wire (773, 273): Used to securely connect solid type wires in outdoor and indoor (buried) junction boxes.

- Push Wire (243): most often used to connect small gauge electrical wires to a single strand.

- Compact Push Wire (2273): these terminal blocks are required for junction boxes, connecting copper and aluminum wires inside them (with a lot of cables).

- Wago Compact (221): used for reusable connection of solid and stranded wires made of aluminum and copper, with a cross section of 0.2 mm² and above.

- Spring terminals (222): suitable for connecting electrical wires from 0.08 mm² and are convenient self-clamping Wago terminals.

- Series 224: has a small socket diameter, as it is intended for connecting fine wires used for lighting fixtures.

- Wago Linec (294): specialized terminals designed for connecting power supplies, as well as for laying three-core wiring with zero, protective earth and phase.

If it is necessary to connect aluminum wires, it is recommended to use Vago terminal blocks with a paste that can reliably protect the tips from oxidation. When purchasing Wago terminal blocks, you can ask the seller or a qualified electrician how to use them. For those who have never used these products, information on wire connections using Vago terminal blocks will be useful.

How to use

The connection of terminal blocks is more reliable than traditional twisting with soldering, thanks to this, the wiring lasts much longer, withstanding high voltage and high current. All modern Vago clamps, which will be used below, have earned respect and recognition from many experts.

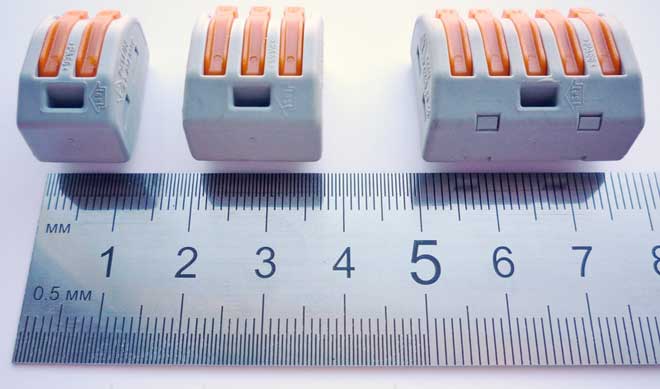

So, as an example, let's take the most popular type of Wago terminal block from the 222 series, to use which we perform the following steps:

- Remove the insulation from the end of the wire about 5 mm.

- Raise the orange clamp in the terminal.

- Insert the end of the bare electrical wire until it stops.

- Lower the clamp until it clicks.

After that, the wire is securely fixed in the socket, the master connects all other wires in the same way. There is nothing complicated about how to use Wago terminals, so many professional craftsmen actively use these pads to connect wires.

If you ask an experienced electrician if it is possible to twist the strands of the wire, he will answer that it is not possible, since the load during the operation of modern household appliances is not small. In this case, the twists may not withstand a large current and overheat, which can lead to a fire. Therefore, it is best to use Vago terminals when installing, allowing you to connect cables safely.

Note! We are talking about poor-quality twisting of wires, without welding.

Giving preference to reliable contacts - Wago terminal blocks, as well as using a copper cable of the desired flow section, the master ensures the reliability of the wiring. In some cases, you can use an aluminum core, but over time they oxidize, and this leads to poor contact. The active use of Vago terminals in practice confirms the high quality of such connections, so the cost of the products is fully justified.

Similar articles: