In the process of creating various power networks, it often becomes necessary to splice several parts of the cable and connect to electrical appliances and apparatus. Such work is carried out using cable fasteners, which are a set of materials and parts necessary for reliable sealing of junctions or branches of electrical conductors. The completeness of the set is different and depends on the parameters of the electric current, the insulating coating and the design of the cable.

Content

Purpose of the cable connector

To unite individual sections of the power cable, cable joints are used. The design and materials used ensure the reliability and durability of the connection. Depending on the purpose, they can be:

- repair;

- transitional;

- branch.

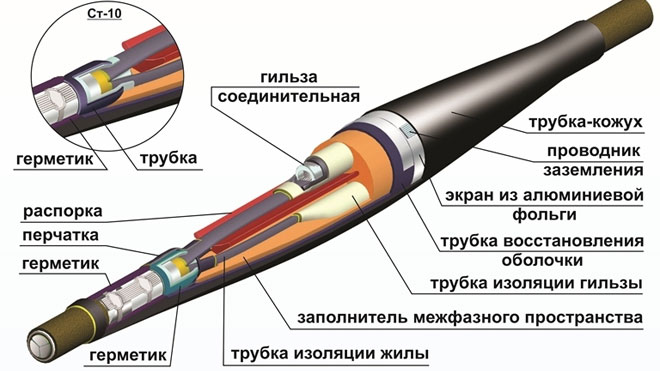

The cable connection sleeve is the most demanded, as it is most often used in the installation of electrical lines.The main requirement for fasteners of this type is the creation of a reliable and tight connection. Due to the fact that the cable box is operated in adverse conditions, the material of manufacture must meet the increased requirements for resistance to the influence of the external environment. Depending on the operating conditions, the sleeves for the cable are made in one piece and collapsible.

Couplings are used for splicing electrical lines of various voltage classes. They provide a reliable connection, seal and protect the junction of single-core and multi-core power cables from damage. When installing power lines on vertical and inclined routes, locking and locking-adaptive cable fasteners are used. It serves not only to connect the conductors, but also prevents the oil-impregnating composition from draining.

Knowing what a cable coupling is, it will not be difficult to choose the necessary model for laying a line in the air or in the ground. A large proportion are products made using cold shrink technology.

Work on docking conductors with paper insulation was simplified by the appearance of heat-shrinkable tubes and gloves. In most cases, these elements are included in the package of electrical products. Heat-shrinkable tubes form a stronger insulating layer, prevent paper winding from unwinding and make the switching process more comfortable.

Conductors are joined by bolted connectors, which are placed in thermotubes.This method is convenient when installing couplings, where conductors with different types of insulation are spliced. With the help of tubes, not only the thickness of the insulating layer is leveled, but also shielding of the docking zone is provided.

Types of connecting cable boxes

Cable fittings used for the construction of power lines are determined by the following characteristics:

- connection type;

- material of manufacture;

- parameters of the transmitted electricity;

- place of installation;

- overall indicators;

- number of cores and shape.

In addition, depending on the material used, the following types of cable sleeves are distinguished:

- epoxy;

- lead;

- shrink;

- cast iron;

- brass;

- rubber.

Epoxy fasteners are designed to connect cables laid in mines, tunnels and trenches. The product has an outer metal or asbestos case. After connecting the cores, it is filled with epoxy.

Lead cable accessories are used for joining cables with a metal or aluminum braid. Available in 2 sizes: normal and small. It is made of lead pipes with a diameter of 60-110 mm, a length of 450-650 mm and depends on the cable section. Such fittings have a large mass. Lead and epoxy sleeves are practically unaffected by external influences and can be used when laying underground.

The most common and simplest method of installing cable fittings is heat shrink construction. After installing the coupling on the area to be joined, it is heated with a building hair dryer or burner until the casing effect appears.The material of the tube is characterized by high insulating properties, and a wide shrinkage range of the material makes it possible to connect cables with different cross-sections of conductors.

Rubber sleeves are used to connect flexible unshielded conductors. At the same time, the connection point remains flexible. No heat is required to install the product. The tightness of the joint is ensured by filling with a special compound.

Recommendations for selection and installation

Installation of end sleeves is carried out when connecting electrical appliances and apparatus. In electrical networks with a voltage of more than 1 kV, fasteners for indoor and outdoor installation are distinguished. At lower voltages, the coupling arrangement allows installation both indoors and outdoors.

To get a reliable joint of cables, it is necessary to choose the right fasteners for the job. To do this, you need to know the following characteristics:

- The voltage of the cable line on which the electrical fittings will be mounted.

- A type of insulating coating of conductors, which can be made of different materials (plastic or oiled paper). This depends on the configuration of the device.

- The number of cores and their cross section. They are determined by the brand of cable or taken from the project documentation.

- The presence of armor. Installation of cable fasteners requires grounding of the armor.

- Mounting type of end sleeves. When choosing an end termination, it is necessary to know the place of installation of the latter (inside or outside the building). The fittings are distinguished by the presence (absence) and the number of anti-tracking heat-shrinkable insulators.

- Product packaging.Delivery can be made with or without bolt connectors and lugs.

Reliable docking of cables is ensured by the use of heat-shrinkable connecting devices. They not only create additional insulation at the installation site, but also allow you to join conductors of different sections.

For the installation of electrical fittings, all layers of insulating material are sequentially removed up to the covering of the cores. Installation of heat-shrinkable sleeves does not require soldering conductors. Contact is ensured through the use of bolted connectors.

When connecting electrical installations to passing lines, it is necessary to create a branch wire. For this, branch clamps and terminal blocks are used. The use of piercing clamps ensures the tightness of the joint and does not require the removal of insulation from the main wire. The clamping force is adjusted by the shear heads of the clamping bolts.

The earth conductor of the terminations is installed using the solderless protection system supplied. To protect the contact point from corrosion, the connection of the conductor with the steel sheath is sealed with a sealing tape.

Installation of cold shrink sleeves does not require heating, which has a positive effect on the time of work. Such devices are able to maintain the flexibility of the cable. They can withstand thermal cycling and ground movement under varying weather conditions.

Similar articles: