Achieving reliable contact when connecting electrical wires is a task that the terminal block helps to solve. There are different designs of such electrical equipment, but all of them are designed to ensure the reliability and safety of wiring at the joints.

Content

The principle of connecting wires

The connection of wires is regulated by the PUE (Electrical Installation Rules). According to them, the most commonly used simple twisting is considered a violation and should be supplemented by soldering, welding or crimping.

At home, crimp terminal blocks of various types serve as a safe and reliable replacement for a solder joint. A non-professional electrician can also switch wires in a junction box or extend a short cable. The principle by which the terminal blocks work is the crimping of each connected end of the conductor with a common structural detail (sleeve, spring, pressure plate, etc.). Metal (steel, brass) does not form an electrochemical pair with copper and aluminum, and the connection lasts longer.The plastic housing serves as an insulator for the connected ends.

In this case, the contact patch is sufficient to ensure the passage of current in full. The main advantage that the terminal block provides for connecting wires is the ability to switch dissimilar cables. With the help of this design, aluminum and copper, solid and stranded conductors can be well spliced. The connecting elements are also convenient for conducting a separate circuit from a common line, if a transition from a conductor with a large cross section to a thinner one is required.

Depending on the type of construction, the sockets can be mounted on a wall or on a panel (terminals for DIN rail) or freely placed in a junction box.

Types of terminal blocks

Regardless of the material from which the housing is made, and the possibility of rigid fixing at the installation site, the terminal blocks are divided into 2 large types:

- screw;

- spring.

This division implies the way in which the ends of the spliced conductors are fixed.

screw

This type is the most common due to its low cost and ease of installation. The device of the screw block includes a sleeve for the wire and a clamping screw. Some models are equipped with a clamping plate, which ensures the safety of the end of the conductor during installation.

Part of the screw connection blocks has 2 inputs, where the ends of the wires to be connected are placed. There are also models with 1 hole, into which both connected ends are inserted. In both cases, to ensure contact between the sleeve and the cables to be connected, it is necessary to tighten a special clamping screw.This part either directly presses on the wire placed in the sleeve, or moves a metal plate that presses it into the socket of the sleeve. The sleeve has a semicircular section. This contributes to creating a larger surface for contact with the conductor.

When choosing a screw block for wiring in a house, it must be taken into account that screw clamps without plates are more often used to connect wires with 1 core. When splicing stranded ends, the edges of the screw often damage the thin wire. But a screw block with a pressure plate is convenient for working with such wires.

If you need to connect cables with different core thicknesses, you should choose a model with separate inputs. Electrical equipment manufacturers produce terminal blocks of different sizes, and the home master needs to choose the most suitable block. At the same time, it should be taken into account that a strong discrepancy between the diameter of the sleeve and the wire will not allow you to reliably press the vein.

The result of such a poor-quality connection will be the rapid oxidation of the contact surfaces and their heating. If necessary, a stripped core that is too thin can be folded in half and twisted to increase its diameter.

Installation of screw models is quite simple:

- Prepare a knife and a slotted screwdriver.

- Remove the insulation from the end of the cables to be connected by 0.7-1 cm.

- Unscrew the screw a little and place the stripped end into the socket so that it is completely immersed there. Do not leave part of the bare conductor outside the block.

- Tighten screw. In order not to damage the stranded or soft aluminum conductor, tighten the screw without force until it presses the wire at the bottom of the sleeve. After that, tighten the screw ¼-1/3 turn.When using a block with a pressure plate, fixing can be done without such precautions by tightening the threaded element until the wire is fixed.

- Check the reliability of fastening by pulling the end installed in the block. If the screw is tightened sufficiently, and the wire is not damaged, then it will not be possible to pull it out of the socket.

Screw-type terminal block models sometimes have mounting holes located between the pairs of contacts. If necessary, such a terminal block can be attached to any surface using self-tapping screws.

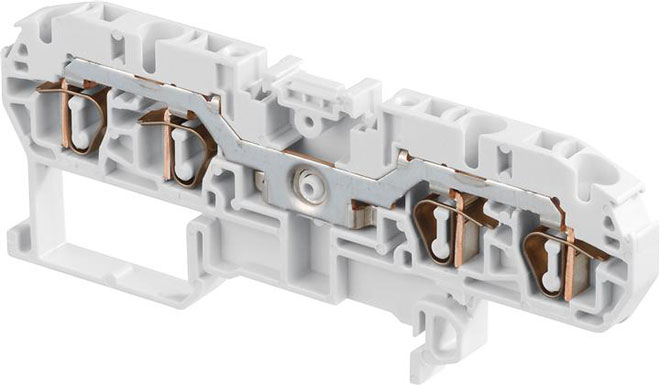

Spring

The fixation of the conductor in the spring-type block is carried out by means of a steel spring of complex shape. The sleeve is made of tinned copper. The movement is housed in a plastic case made from a material that can withstand high temperatures (polycarbonate, polyamide, etc.). The metal parts are inside, and the case serves as an insulator for the connection.

On the Russian market, WAGO products are most common. Manufacturers produce spring (clamp) terminal blocks of 2 varieties:

- Disposable one-piece, or Puch Wire. They snap into place on their own after the end of the wire is inserted into the sleeve. If it is necessary to replace the terminal block in the event of a breakdown, you will have to completely cut off the electrical installation and change it to another one. These items are not disassembled.

- Reusable, or Cage Clamp. These models have a plastic lever, when pressed, the wire is fixed in the socket, and when lifted, the end can be released.

Spring terminal blocks have 2-8 sockets and are designed for a rated voltage of 220 V at a current of 32 A.The dimensions of the connecting products can be selected for different cables, with a cross section of 0.5-4 mm². Some models have a DIN rail mount, but there are also terminal blocks without a mount.

Connect the wires with spring blocks in the following order:

- The connected end is cleaned to a length of 1-1.3 cm.

- At the one-piece terminal block, open the clamp with the end of a screwdriver, insert the conductor into it and remove the screwdriver. The spring will lock automatically. The reusable block is opened by lifting the lever. To snap the spring into place, it is lowered into a specially designed recess on the body.

- Check the reliability by pulling on the cable.

When installing the connection with such blocks, it should be noted that only 1 conductor should be placed in each socket.

The advantages of such a connection are that it is performed quickly and reliably, does not require special knowledge and tools. To control the presence of voltage on the terminal block, there are special holes for a probe-screwdriver.

Disadvantages of pads

Clamping connection of different types has tangible disadvantages:

- Some electricians believe that spring products are not well suited for heavy loads. It is recommended to mount terminal blocks for low-current circuits: lighting, economical household appliances, etc.

- Screw terminals do not hold aluminum wires well. Even if the connection is made correctly, it weakens over time. It is recommended to check such electrical installations 1-2 times a year and re-tighten the screws.

Even a high-quality terminal connection is not very durable due to the oxide film formed on metal surfaces.

Similar articles: