Many motorists have trailers in their households for transporting bulky goods. In accordance with the current Rules of the Road, any towed vehicle (BTS) must be equipped with serviceable light signals. The trailer is connected to the car's electrical network by means of a plug and socket. To synchronize the signals of both vehicles, there is a universal trailer connection scheme and towbar socket pinout.

Content

Types of connectors and connection diagrams

There are several types of automotive electromechanical plug devices, in particular:

- 7-pin;

- 13-pin;

- 15 pin.

Some American cars use four-pin sockets.

Semi-pin connectors can be of European and American design. In Russia, the European pinout is most often used. Such a wiring diagram for a trailer socket is simple, so most motorists make it on their own.

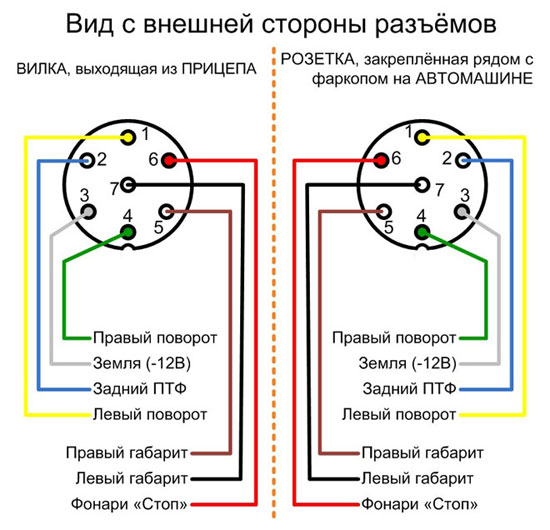

The wires are attached to the contacts with screws. The numbering of the pins of the towbar connector is clockwise, and in the plug on the trailer - against. In both parts of the connector there are contacts of different types - sockets and pins. This is to ensure safety when connecting the socket to the trailer at night.

Ways to connect the towbar socket

To connect the electrical wiring of the car and trailer, you can use 2 options:

- regular;

- universal.

A regular connection is used if the car has a special connector designed for this purpose. The motorist only needs to connect the plug and socket. If the latter is absent, then it is necessary to connect the wiring of the towbar socket with a chip suitable for the standard connector. In this case, the driver does not interfere with the electrical circuit of the car.

In cars with a factory connector, the pinout diagram is given in the instruction manual. This connection option applies to some models of foreign cars. In most cases, connecting the towbar socket to a domestic-made car is carried out in a universal (direct) way.

In models of cars that do not have an on-board computer, the work is reduced to connecting the wires of the socket for the towbar to the harness block of one of the rear light units. The connection can be made using special clips or using soldering.The latter method is less time consuming, and the wire connection is more durable.

If the rear optics in the car is controlled by the on-board computer, then a simple direct connection cannot be made, because. when the load increases when the lights are turned on, the automotive electronics will generate an error. This can be avoided by connecting using a matching block. Then the corresponding signals to the lighting equipment will come not from the blocks of the lamp block, but from the installed electronic device. With this connection method, the onboard electronics do not see the electrical equipment of the trailer.

Schemes of various types of sockets

On domestic-made cars, 7-pin electrical connectors are most often installed. They provide the transmission of all signals from the car to the BTS. If a trailer is to be connected instead of a cargo trailer, then a 13-pin socket is used. For electrical wiring (pinout), double-insulated stranded wires with a core cross section of at least 1.5 mm² are used. To protect the tourniquet from damage, it is placed in a corrugated sleeve.

Pinout of a 7-pin socket

If the car does not have a regular connector for connecting the trailer, then install the outlet bought in the store on a special plate near the towbar. In this case, the pinout is done in a universal way. To do this, the wires are directly connected by soldering to the corresponding terminals of the rear light terminal blocks.

The pinout of a 7-pin socket looks like this:

- 1 - left turn;

- 2 - fog lamp;

- 3 - "mass";

- 4 - right turn signal;

- 5 - reversing lamp;

- 6 - brake light;

- 7 - marker lights and room lighting

In some European vehicles, the rear fog lamp contact may not be engaged.

The control signals from the direction indicators are removed from both sides and brought to the outlet with different wires. The indication of the rest of the lighting equipment can be taken from one block of rear lights.

Pinout of a 13-pin socket

Most imported cars are equipped with standard connectors for 13 pins. If there is no towbar in the car, then in most cases a 7-pin socket is installed. When one of the vehicles has a 13-pin socket and the other has a 7-pin plug, the connection is made using an adapter.

Unlike the 7-pin, the 13-pin socket additionally has 3 outputs with "ground", and through 2 power is supplied and 12 V from the battery. 1 pin remains unused. Lamps of dimensions are powered through different conductors: each on its own side.

To install the towbar on the Chevrolet Niva, a standard set of wires with end connectors is used, which are connected directly to the contact chips of the rear light optics.

Pinout of the 15-pin connector

This type of connector is used to connect towed vehicles to a tractor in most countries of the world. The connector not only receives a signal from the direction indicator and brake light, but also transmits feedback to the truck driver about the state of the brake systems and controls some of the BTS mechanisms. The rest of the pinout is similar to a 13-pin socket.These electrical connectors are used only on heavy trucks.

Direct connection schemes

This type of connection is used when there is no standard terminal block in the car. In this case, the wires are connected directly to the rear light harness. To facilitate installation, you can use connectors equipped with plug-in connectors for mating with optics. On the other side of the device there are wires for connecting to the counterpart of the device.

Before connecting the towbar socket, it is necessary to determine the location of the connectors. They are connected to lighting equipment through technological cutouts designed to replace lamps, and the output of the harness to the outside is through drainage in the bottom of the trunk. In some cases, the scheme for connecting the socket to the towbar involves soldering wires. Such connections are more durable.

If it is planned to combine two contacts, for example, the dimensions of the starboard and port side, then the common output wire must be more than 2 mm² in cross section, because his workload will increase. You can buy the necessary components in the store or at the car market. You should not buy connectors and connectors of handicraft production, because. this is fraught with a short circuit with further ignition of the entire wiring.

Step by step connection to the machine

Before connecting the socket to the towbar, you need to prepare the following materials:

- connector with cover;

- connecting blocks;

- multi-core cable in colored insulation with a core cross section of at least 1.5 mm²;

- protective corrugated tube;

- plastic clamps.

For a car with an on-board computer, you must additionally purchase a matching unit.

Work on connecting the connector is carried out in the following order:

- Prepare wires of the required size.

- Remove the insulation and tin the ends or crimp them into brass sleeves. This will increase the strength of the connection and eliminate heat.

- Fasten the wires in the connectors.

- The resulting tourniquet is placed in a corrugated sleeve.

- Fix the removable part in the socket housing.

- Solder the wires in the connecting blocks according to the scheme.

- Connect the latter to the light optics connectors of both lights.

- Lay the harness, fixing it with clamps on the body parts, and install the plugs on the technological holes.

After installation is complete, connect the trailer and check the operation of the circuit. If there are no comments, then seal with silicone the places of possible water ingress into the electrical parts of the connection. To prevent oxidation of the contacts, lubricate them with technical vaseline or graphite grease.

Correctly carried out pinout and installation will allow you to quickly connect the trailer, without wasting time checking the correct connection of the terminals.

Similar articles: