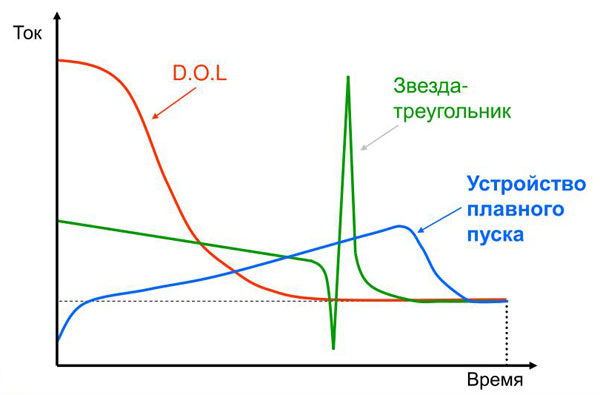

Electric motors are simple and reliable machines, but they also have some drawbacks that make them difficult to use. In particular, at start-up, such devices have high current consumption values and, without special devices, they start with a jerk due to a mismatch between the engine torque and the load on its shaft. Additional devices that ensure smooth operation of the engine at startup and reduce starting currents are called soft starters.

Content

What is a soft starter

Soft starter (SCP) is an electrical device that is used in the operation of asynchronous motors and allows you to control and manage its start and parameters for safe operation in an alternating current network.Such a device reduces the impact on the engine of a number of negative factors, including reduces the likelihood of increased engine heating, eliminates jerks, providing a smooth start and exit to the workload. Also, soft starters reduce the negative impact on the electrical network by reducing the starting currents of the electric motor.

Often, electrical specialists and people associated with the operation of electric motors refer to soft starters as "soft starters". This is due to the fact that in English (and most high-quality devices are imported) these devices are called soft starter, which means "soft starter".

Soft start of electric motors with frequency converters and soft starters allows you to solve a large number of tasks and control the operation of the electric motor in a wide range of its parameters. Especially often, soft starters are used when working in conditions of difficult start-up (with high inertia or starting under load with four times the starting current, with a motor acceleration of at least 30 seconds) and especially heavy start (with six or eight times the starting currents and long motor acceleration times).

The soft starter is also used at reduced or limited power of the electrical network, when inrush currents can create significant overloads in the network, including with an effect on automatic protective equipment, which, at high values of inrush current, even for a short time, turns off the power.

The scope of application of soft starters is quite extensive: they are used in the operation of pumping units, in ventilation and compressor equipment, on electric motors of heavy industries and in construction, in crushing equipment, on conveyors, escalators and in other mechanisms and equipment.

Principle of operation

Main disadvantage asynchronous electric motors - this is that the moment of force on the shaft is proportional to the square of the voltage that is applied to the electric motor. This creates strong jerks during start-ups and at the moment of termination of operation, which also increases the values of the induction current.

Soft starters can be mechanical and electrical, as well as combined, combining the positive features of both devices.

Mechanical soft starters operate on the principle of counteracting a sharp increase in the speed of an electric motor by mechanically affecting its rotor using brake pads, various clutches, counterweights, magnetic interlocks and other mechanisms. Such mechanisms have not been used often recently, as there are more advanced electrical control devices.

Electric starters gradually increase the current or voltage from the reference level to the maximum, which allows you to smoothly increase the speed of the electric motor and reduce loads and starting currents. Most often, electrical soft starters are controlled electronically using computer systems or electronic devices, which allows you to change the starting parameters and control the dynamic characteristics.Soft starters allow you to change the operating modes of the electric motor depending on the applied load and allow you to implement one or another relationship between the shaft rotation speed and voltage.

The principle of operation of electrical devices is based on two methods:

- The method of limiting the current in the rotor winding is implemented using coils connected according to the "star" scheme;

- The method of limiting the voltage and current in the stator (using thyristors, triacs or a rheostat).

According to the method of adjustment, one-, two- and three-phase devices are also distinguished. A soft starter with voltage regulation in one phase is used for equipment up to 10 kW, the positive moments with such regulation are the reduction of dynamic shocks and jerks at start-up, the negative ones are asymmetrical load at start-up and high starting currents. Soft starters with two-phase adjustment allow to reduce starting currents and motor heating at start and are used in medium-heavy starting conditions. Three-phase soft starters significantly reduce starting currents and allow you to smoothly stop the motor, as well as provide an emergency shutdown. Such devices are used for heavy starting with a significant load, as well as with frequent engine on / off.

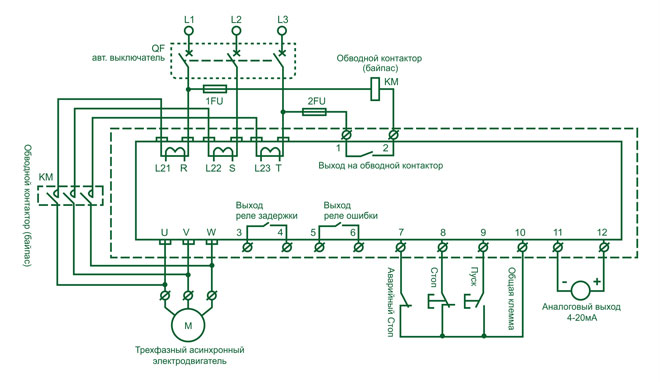

Scheme of connecting the electric motor to the soft starter

In order to connect the soft starter to the electric motor and mains, you should be guided by the instructions for this type of device, it will indicate all important aspects when connecting: circuit sequence, ground and neutral terminals, as well as the correct start, acceleration and braking setup.But in general, there are standard connection methods that are suitable for most soft starters.

Each soft starter has a contact at the input and the same number at the output for connecting phases, a start and stop control system (START, STOP buttons), other buttons and control contacts. Supply cables are connected to the device to the input terminals (usually these are the designations L1, L2, L3), and from the output terminals (designations T1, T2, T3) connect the motor. At the same time, it is important to connect the soft starter to the network through introductory circuit breaker and when connecting the motor to the soft starter and the soft starter itself to the mains, use cables with a nominal cross section corresponding to the limit value of the motor current.

Some devices can be controlled not only from switches and control devices on the device itself, but also through relay or controller contacts - this complicates the connection diagram of the device, but expands its capabilities.

What are the criteria for selecting a soft starter

There are several important criteria that allow you to choose the right soft starter for the electric motor and its operating modes.

- Motor current: The soft starter is selected based on the full load current of the motor, which must not be higher than the maximum load current of the soft starter. It is best if the current that the softstarter is rated for is higher than the maximum load current of the motor.

- Starts per hour limit: most often this parameter is limited by the type of soft starter and for reliable and durable operation of the device it is important that this parameter does not exceed the allowable for a particular device.

- Supply voltage: soft starters differ in their functionality and operation in networks with different voltages, so the voltage must correspond to the nameplate value of the device.

All these parameters must be indicated in the passport for the soft starter and the selection for the specific operating conditions of the electric motor and the supply network must be selected in a mandatory case when choosing a soft starter.

Similar articles: