Science in the field of electricity in the 19th and 20th centuries developed rapidly, which led to the creation of electric induction motors. With the help of such devices, the development of the industrial industry has stepped far forward and now it is impossible to imagine plants and factories without power machines using asynchronous electric motors.

Content

History of appearance

The history of the creation of an asynchronous electric motor begins in 1888, when Nikola Tesla patented an electric motor circuit, in the same year another scientist in the field of electrical engineering Gallileo Ferraris published an article on the theoretical aspects of the operation of an asynchronous machine.

In 1889 the Russian physicist Mikhail Osipovich Dolivo-Dobrovolsky received a patent in Germany for an asynchronous three-phase electric motor.

All these inventions made it possible to improve electrical machines and led to the massive use of electrical machines in industry, which significantly accelerated all technological processes in production, increased work efficiency and reduced its labor intensity.

At the moment, the most common electric motor used in industry is the prototype of an electric machine created by Dolivo-Dobrovolsky.

The device and principle of operation of an asynchronous motor

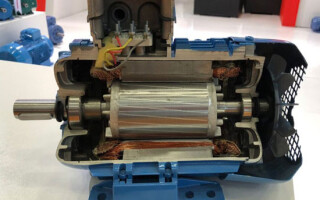

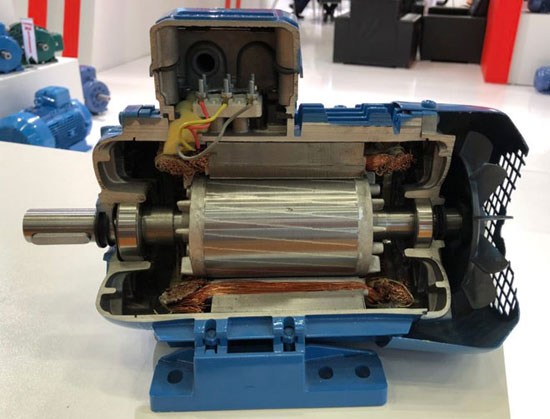

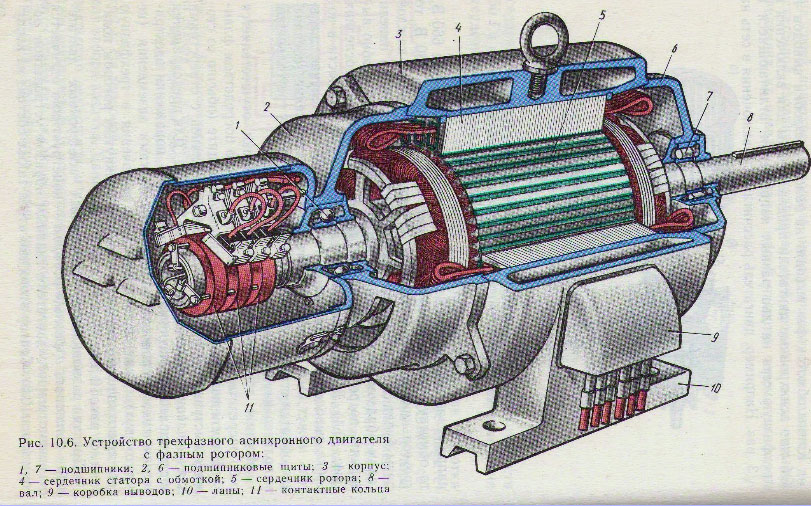

The main components of an induction motor are the stator and rotor, which are separated from each other by an air gap. Active work in the engine is performed by the windings and the core of the rotor.

The asynchrony of the engine is understood as the difference between the rotor speed and the frequency of rotation of the electromagnetic field.

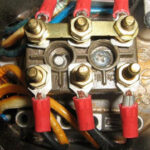

stator - this is a fixed part of the engine, the core of which is made of electrical steel and mounted in the frame. The bed is made in a cast way from a material that is not magnetic (cast iron, aluminum). The stator windings are a three-phase system in which the wires are laid in grooves with a deflection angle of 120 degrees. The phases of the windings are standardly connected to the network according to the "star" or "triangle" schemes.

Rotor It is the moving part of the engine. The rotors of asynchronous electric motors are of two types: with squirrel-cage and phase rotors. These types differ from each other in the designs of the rotor winding.

Asynchronous squirrel-cage motor

This type of electric machine was first patented by M.O. Dolivo-Dobrovolsky and is popularly called "squirrel wheel" due to the appearance of the structure. The short-circuited rotor winding consists of copper rods short-circuited with rings (aluminium, brass) and inserted into the grooves of the winding of the rotor core. This type of rotor does not have moving contacts, so these motors are very reliable and durable in operation.

Induction motor with phase rotor

Such a device allows you to adjust the speed of work in a wide range. The phase rotor is a three-phase winding, which is connected according to the "star" or triangle schemes. In such electric motors, there are special brushes in the design, with which you can adjust the speed of the rotor. If a special rheostat is added to the mechanism of such an engine, then when the engine is started, the active resistance will decrease and thereby the starting currents will decrease, which adversely affect the electrical network and the device itself.

Operating principle

When an electric current is applied to the stator windings, a magnetic flux occurs. Since the phases are shifted relative to each other by 120 degrees, because of this, the flow in the windings rotates. If the rotor is short-circuited, then with such rotation, a current appears in the rotor, which creates an electromagnetic field. Interacting with each other, the magnetic fields of the rotor and stator cause the rotor of the electric motor to rotate. If the rotor is phase, then voltage is applied to the stator and rotor simultaneously, a magnetic field appears in each mechanism, they interact with each other and rotate the rotor.

Advantages of asynchronous motors

| with squirrel-cage rotor | With phase rotor |

|---|---|

| 1. Simple device and launch circuit | 1. Small starting current |

| 2. Low manufacturing cost | 2. Ability to adjust the rotation speed |

| 3. With increasing load, the shaft speed does not change | 3. Work with small overloads without changing the speed |

| 4. Capable of withstanding short-term overloads | 4. Automatic start can be applied |

| 5. Reliable and durable in operation | 5. Has a large torque |

| 6. Suitable for all working conditions | |

| 7. Has a high efficiency |

Disadvantages of asynchronous motors

| with squirrel-cage rotor | With phase rotor |

|---|---|

| 1. Rotor speed is not adjustable | 1. Large dimensions |

| 2. Small starting torque | 2. Efficiency is lower |

| 3. High starting current | 3. Frequent maintenance due to brush wear |

| 4. Some design complexity and the presence of moving contacts |

Asynchronous motors are very efficient devices with excellent mechanical characteristics, which makes them leaders in frequency of use.

Operating modes

An asynchronous type electric motor is a universal mechanism and has several modes for the duration of operation:

- Continuous;

- short-term;

- Periodic;

- Repeated-short-term;

- Special.

Continuous mode - the main mode of operation of asynchronous devices, which is characterized by the constant operation of the electric motor without shutdowns with a constant load. This mode of operation is the most common, used in industrial enterprises everywhere.

Momentary mode - works until a constant load is reached for a certain time (10 to 90 minutes), not having time to warm up as much as possible. After that it turns off. This mode is used when supplying working substances (water, oil, gas) and other situations.

Periodic mode - the duration of work has a certain value and is turned off at the end of the cycle of work. Operating mode start-work-stop. At the same time, it can turn off for a time during which it does not have time to cool down to external temperatures and turn on again.

Intermittent mode - the engine does not heat up to the maximum, but also does not have time to cool down to the external temperature. It is used in elevators, escalators and other devices.

special regime - the duration and period of inclusion is arbitrary.

In electrical engineering, there is a principle of reversibility of electrical machines - this means that the device can both convert electrical energy into mechanical energy and perform the opposite actions.

Asynchronous electric motors also correspond to this principle and have a motor and generator mode of operation.

Motor mode - the main mode of operation of an asynchronous electric motor. When voltage is applied to the windings, an electromagnetic torque arises, dragging the rotor with the shaft, and thus the shaft begins to rotate, the engine reaches a constant speed, doing useful work.

generator mode - based on the principle of excitation of electric current in the motor windings during the rotation of the rotor. If the motor rotor is rotated mechanically, then an electromotive force is formed on the stator windings, in the presence of a capacitor in the windings, a capacitive current occurs.If the capacitance of the capacitor is a certain value, depending on the characteristics of the engine, then the generator will self-excite and a three-phase voltage system will appear. Thus, the squirrel-cage motor will work as a generator.

Speed control of asynchronous motors

To regulate the speed of rotation of asynchronous electric motors and control their operating modes, there are the following methods:

- Frequency - when the frequency of the current in the electrical network changes, the frequency of rotation of the electric motor changes. For this method, a device called a frequency converter is used;

- Rheostatic - when the resistance of the rheostat in the rotor changes, the rotational speed changes. This method increases the starting torque and critical slip;

- Pulse - a control method in which a special type of voltage is applied to the motor.

- Switching the windings during the operation of the electric motor from the “star” circuit to the “triangle” circuit, which reduces starting currents;

- Management from change of pairs of poles for squirrel-cage rotors;

- Connection of inductive reactance for motors with phase rotor.

With the development of electronic systems, the control of various asynchronous type electric motors is becoming more efficient and accurate. Such engines are used everywhere in the world, the variety of tasks performed by such mechanisms is growing every day, and the need for them is not decreasing.

Similar articles: