People use the energy of electric current in almost all areas of their activities. Now it is not easy to imagine life without electricity, which is converted from mechanical energy with the help of special equipment. Let us consider in more detail how this process takes place, and how modern generators are arranged.

Content

Converting mechanical energy into electrical energy

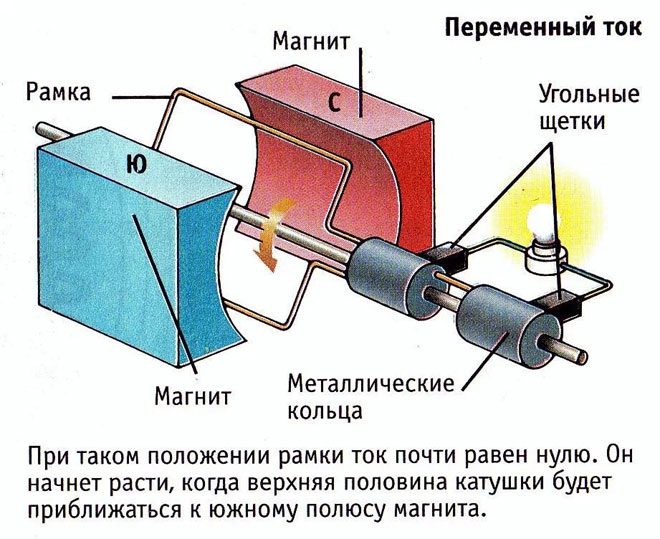

Any generator works on the principle of magnetic induction. The simplest alternator can be thought of as a coil that rotates in a magnetic field. There is also a variant in which the coil remains stationary, but the magnetic field only crosses it. It is during this movement that an alternating current is generated.According to this principle, a huge number of generators around the world operate, combined into a power supply system.

The device and design of the alternator

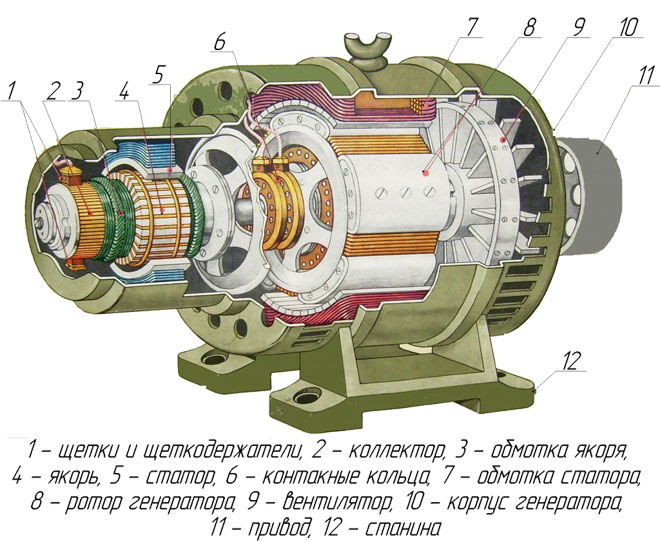

A standard power generator has the following components:

- A frame to which a stator with electromagnetic poles is attached. It is made of metal and must perform the protective function of all elements of the mechanism.

- The stator to which the winding is attached. It is made from ferromagnetic steel.

- A rotor is a movable element, on the core of which there is a winding that forms an electric current.

- A switching unit that diverts electricity from the rotor. It is a system of movable conductive rings.

Depending on the purpose, the generator has certain design features, but there are two components that any device that converts mechanical energy into electricity has:

- The rotor is a movable one-piece iron part;

- The stator is a fixed element that is made of iron sheets. Inside it there are grooves inside which the wire winding is located.

To obtain greater magnetic induction, there should be a small distance between these elements. According to their design, generators are:

- With movable armature and static magnetic field.

- With fixed armature and rotating magnetic field.

At present, equipment with rotating magnetic fields is more common, because. it is much more convenient to remove electric current from the stator than from the rotor. The generator device has many similarities with the design of the electric motor.

Alternator circuit

The principle of operation of the electric generator: at the moment when half of the winding is on one of the poles, and the other on the opposite, the current moves through the circuit from the minimum to the maximum value and vice versa.

Classification and types of generators

All electric generators can be distributed according to the criterion of work and the type of fuel from which electricity is generated. All generators are divided into single-phase (voltage output 220 Volts, frequency 50 Hz) and three-phase (380 Volts with a frequency of 50 Hz), as well as the principle of operation and the type of fuel that is converted into electricity. Even generators can be used in different areas, which determines their technical characteristics.

According to the principle of work

Separate asynchronous and synchronous alternators.

Asynchronous

Asynchronous generators do not have an exact relationship EMF on the rotor speed, but the term "slip S" works here. It defines this difference. The slip value is calculated, so there is still some influence of the generator elements in the electromechanical process of the induction motor.

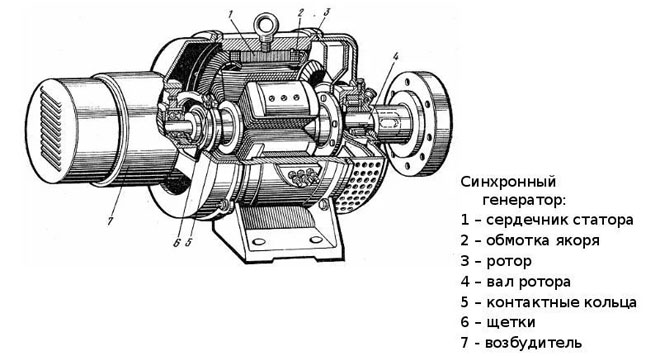

Synchronous

Such a generator has a physical dependence on the rotational movement of the rotor to the generated frequency of electricity. In such a device, the rotor is an electromagnet consisting of cores, windings and poles. The stator are coils that are connected according to the principle of a star, and having a common point - zero. It is in them that electricity is generated.

The rotor is set in motion by an extraneous force of moving elements (turbines) that move synchronously. The excitation of such an alternator can be both contact and non-contact.

By type of engine fuel

Remoteness from the mains with the advent of generators no longer becomes an obstacle to the use of electrical appliances.

gas generator

Gas is used as a fuel, during the combustion of which mechanical energy is generated, which is then replaced by electric current. Benefits of using a gas generator:

- Safety for the environment, because the gas during combustion does not emit harmful elements, soot and toxic decomposition products;

- Economically, it is very profitable to burn cheap gas. Compared to gasoline, it will cost much less;

- Fuel supply is carried out automatically. Gasoline and diesel fuel need to be added as needed, and the gas generator is usually connected to the gas supply system;

- Thanks to automation, the device comes into action independently, but for this it must be located in a warm room.

Diesel generator

This category consists mainly of single-phase units with a capacity of 5 kW. 220 Volts and a frequency of 50 Hz are standard for household appliances, so the diesel machine copes well with a standard load. As you might guess, diesel fuel is required for its operation. Why Choose Diesel Generator?

- Relative cheapness of fuel;

- Automation that allows you to automatically start the generator when the power supply is interrupted;

- High level of fire safety;

- For a long period of time, a diesel unit is able to work without failures;

- Impressive durability - some models are able to work for a total of 4 years of continuous operation.

Petrol generator

Such devices are quite in demand as household equipment. Despite the fact that gasoline is more expensive than gas and diesel, such generators have many strengths:

- Small dimensions with high power;

- Easy to operate: most models can be manually started, and larger generators are equipped with a starter. The voltage is regulated under a certain load using a special screw;

- In the event of an overload of the generator, protection is automatically activated;

- Easy to maintain and repair;

- Do not make a lot of noise during operation;

- Can be used both indoors and outdoors, but should be protected from moisture.

Main Applications

Depending on where the generator is used, its technical characteristics are determined. Mainly, the ratio of the generator to a certain category in the field of application determines its power. The following types of equipment are divided by areas of operation:

- Household. They have power from 0.7 to 25 kW. Typically, this category includes gasoline and diesel generators. They are used to power household electrical appliances and low-power equipment, very often on construction sites. Suitable as a portable source of electricity when going out into the countryside;

- Professional. They can be used as a permanent source of electricity in municipal institutions and small manufacturing enterprises. Its power does not exceed 100 kW;

- Industrial.They can be used in large factories and plants where high-power equipment is required. Such devices have a power of more than 100 kW, have considerable dimensions and are difficult to maintain for an unprepared person.