Everyday life of a person is inextricably linked with electric motors of various configurations, on the basis of which the operation of various devices and equipment is based. We use such equipment constantly and quite often there are various malfunctions in their operation, which is often associated with a malfunction of the electric motor. In order to bring the device into working condition, you need to know how to ring the electric motor. This will be discussed in this article.

Content

Which electric motors can be checked with a multimeter

If the motor has no obvious external damage, then there is a possibility that an internal open circuit or short circuit has occurred. But not all electric motors can be simply checked for these defects. multimeter.

For example, it may be difficult to diagnose DC motors, since their winding has almost zero resistance and it can only be checked by an indirect method according to a special scheme: they simultaneously take readings from an ammeter and a voltmeter with the calculation of the resulting resistance value according to Ohm's law.

Thus, all the resistances of the armature windings are checked and the values \u200b\u200bof the collector plates are measured. If the armature winding resistances differ, then there is a problem, since in a working machine these values are the same. The difference in resistance values between adjacent collector plates should be no more than 10%, then the engine will be considered serviceable (but if the design provides for an equalizing winding, then this value can reach up to 30%).

AC electric machines are divided into:

- synchronous: having stator windings located at the same offset angle between themselves, which allows you to move at a frequency that is synchronous with the rotation speed of the applied force;

- asynchronous with squirrel-cage rotor (one- or three-phase);

- asynchronous with a phase rotor, having a three-phase winding;

- collector.

All these types of engines are available for diagnostics using measuring instruments, including multimeters. In general, AC motors are quite reliable machines and malfunctions in them are quite rare, but they do happen.

What malfunctions in the electric motor can be detected by a multimeter

Quite often, a multimeter is used to test AC motors - a multifunctional electronic measuring device. It is available from almost every home master and allows you to identify some types of malfunctions in electrical appliances, including electric motors.

The most common malfunctions that occur in electrical machines of this type are:

- open winding (rotor or stator);

- short circuit;

- interturn closure.

Let's consider each of these problems in more detail and analyze the methods for identifying such malfunctions.

Winding breakage or integrity check

A winding break is a fairly common occurrence when a motor malfunction is detected. An open in the winding can happen both in the stator and in the rotor.

If one phase was cut off in the winding connected according to the “star” scheme, then there will be no current in it, and in other phases the current values \u200b\u200bwill be overestimated, while the engine will not work. There may also be a break in the parallel branch of the phase, which will lead to overheating of the serviceable branch of the phase.

If one phase of the winding (between two conductors) connected according to the “triangle” scheme was cut off, then the current in the other two conductors will be much less than in the third conductor.

If a break occurs in the rotor winding, then current fluctuations will occur with a frequency equal to the slip frequency and voltage fluctuations, while a buzz will appear and the engine speed will be reduced, and vibration will also occur.

These reasons indicate a malfunction, but the malfunction itself can be identified by dialing and measuring the resistance of each motor winding.

AT engines, designed for an alternating voltage of 220 V, the starting and working windings are called. The resistance value of the starting winding should be 1.5 times greater than the working winding.

In 380 V motors that are connected according to the “star” or “triangle” schemes, the entire circuit must be disassembled and each winding must be checked separately. The resistance of each of the windings of such an electric motor must be the same (with a deviation of no more than five percent). But in the event of a break, the multimeter display will show a high resistance value that tends to infinity.

You can also check the motor windings using the function multimeter "dialing". This method allows you to quickly detect an open in the circuit, since there will be no sound signal, in a working circuit the multimeter will make a sound, and a light indication is also possible.

Short circuit test

Also a common fault in electric motors is a short circuit to the housing. To identify this malfunction (or its absence), perform the following actions:

- resistance measurement values with a multimeter are set to the maximum;

- the probes are interconnected to check the health of the measuring device;

- one probe is connected to the motor housing;

- the second probe is connected in turn to the terminals of each phase;

The result of such actions with a working engine will be high resistance (several hundred or thousand megaohms).It is even more convenient to check the breakdown on the case with the "ringing" of the multimeter: you need to carry out all the same actions described above in the continuity mode and the presence of an audible signal will mean a violation in the integrity of the winding insulation and a short circuit to the case. By the way, this malfunction not only negatively affects the operation of the equipment itself, but is also dangerous to human life and health in the absence of special protective devices.

Turn-to-turn short circuit test

Another type of malfunction is an interturn circuit - a short circuit between different turns of one motor coil. With such a malfunction, the motor will hum and its power will noticeably decrease.

There are several ways to detect such a malfunction. For example, you can use a current clamp or a multimeter.

When diagnosing with the help of current clamps, the current values \u200b\u200bof each of the phases of the stator winding are measured, and if the current value in one of them is overestimated, then there is a short circuit.

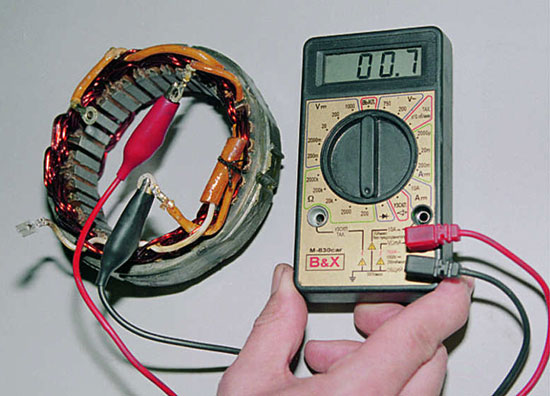

Measurement with a multimeter is carried out in the resistance measurement mode. The resistance of all three windings must be the same. At the same time, it is important to understand that the device must be used with as little error as possible, since the difference in resistances can be small and difficult to detect.

To measure the resistance of the windings, the multimeter probes are connected to the ends of different turns and check for contact in the “ringing” mode or by measuring the resistance. With a difference in measurements of more than 10%, there is a possibility of a short interturn circuit.

Similar articles: