The system of three-phase electric current was developed at the end of the 19th century by the Russian scientist M.O. Dolivo-Dobrovolsky. Three phases, the voltage in which is shifted relative to each other by 120 degrees, among other advantages, make it easy to create a rotating magnetic field. This field carries with it the rotors of the most common and simplest three-phase asynchronous motors.

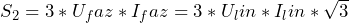

The three stator windings of such electric motors are in most cases interconnected according to the "star" or "triangle" scheme. In foreign literature, the terms "star" and "delta" are used, abbreviated as S and D. The mnemonic designation D and Y is more common, which can sometimes lead to confusion - the letter D can be marked both "star" and "triangle".

Content

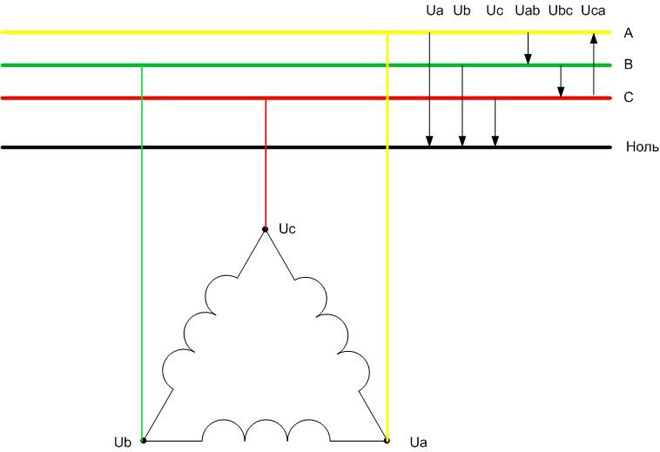

Phase and line voltages

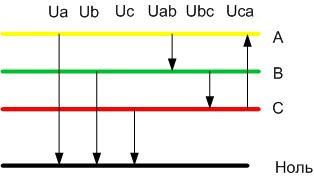

To understand the differences between the ways of connecting the windings, you first need to understand with the concepts of phase and linear voltages. Phase voltage is the voltage between the beginning and end of one phase. Linear - between the same conclusions of different phases.

For a three-phase network, line-to-line voltages are voltages between phases, for example, A and B, and phase voltages are between each phase and the neutral conductor.

So the voltages Ua, Ub, Uc will be phase, and Uab, Ubc, Uca will be linear. These voltages are different. So, for a household and industrial network of 0.4 kV, the linear voltages are 380 volts, and the phase voltages are 220 volts.

Connection of motor windings according to the "star" scheme

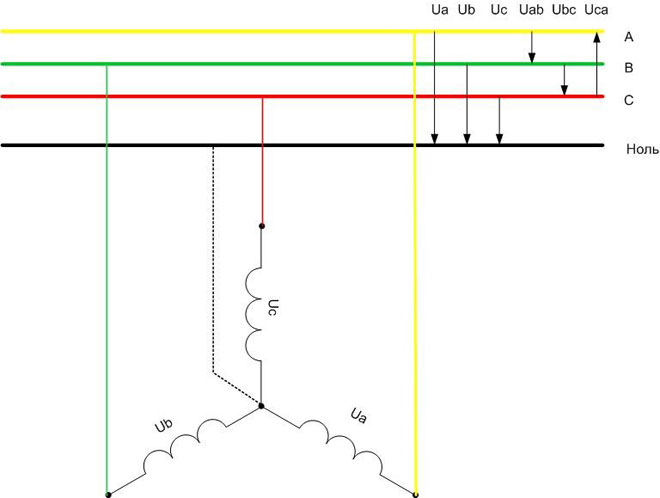

When connecting the phases of an electric motor with a star, the three windings are interconnected at their beginnings at a common point. The free ends are connected each to their own phase of the network. In some cases, the common point is connected to the neutral bus of the power supply system.

It can be seen from the figure that for this inclusion, the phase voltage of the network is applied to each winding (for networks of 0.4 kV - 220 volts).

Connecting the motor windings according to the "triangle" scheme

With the "triangle" scheme, the ends of the windings are connected to each other in series. It turns out a kind of circle, but in the literature the name “triangle” is accepted because of the often used style. There is nowhere to connect the neutral wire in this embodiment.

Obviously, the voltages applied to each winding will be linear (380 volts per winding).

Comparison of connection schemes with each other

To compare both schemes with each other, it is necessary to calculate the electric power developed by the electric motor during one or another inclusion. For this, it is necessary to consider the concepts of linear (Ilin) and phase (Iphase) currents.Phase current is the current flowing through the phase winding. Linear current flows through a conductor connected to the winding terminal.

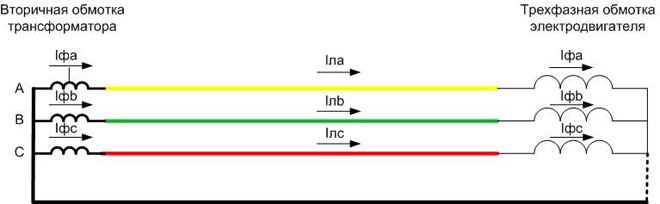

In networks up to 1000 volts, the source of electricity is transformer, the secondary winding of which is turned on by a "star" (otherwise it is impossible to organize a neutral wire) or a generator whose windings are connected in the same way.

The figure shows that when connected with a "star", the currents in the conductors and the currents in the motor windings are equal. The phase current is determined by the phase voltage:

![]()

where Z is the resistance of the winding of one phase, they can be taken equal. It can be written that

![]()

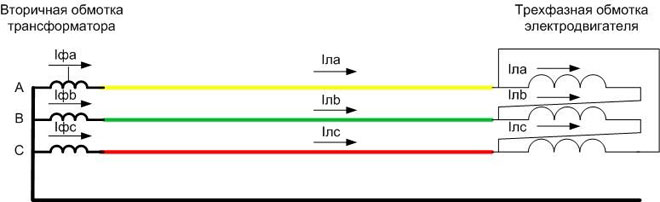

For a delta connection, the currents are different - they are determined by the linear voltages applied to the resistance Z:

![]()

Therefore, for this case ![]() .

.

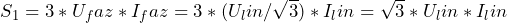

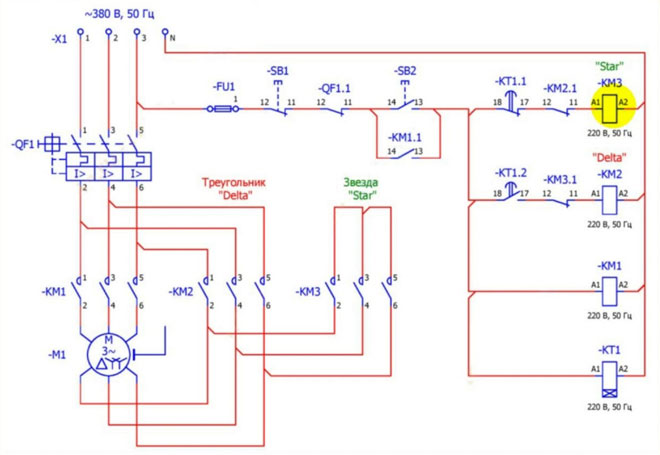

Now we can compare the total power (![]() ), consumed by electric motors with different circuits.

), consumed by electric motors with different circuits.

- for a star connection, the total power is

;

; - for a delta connection, the total power is

.

.

Thus, when turned on by a “star”, the electric motor develops power three times lower than when connected to a delta. It also leads to other positive consequences:

- starting currents are reduced;

- engine operation and start-up become smoother;

- the electric motor copes well with short-term overloads;

- the thermal regime of the asynchronous motor becomes more gentle.

The flip side of the coin is that a star-wound motor cannot develop maximum power. In some cases, the torque may not even be enough to spin the rotor.

Ways to switch star-delta circuits

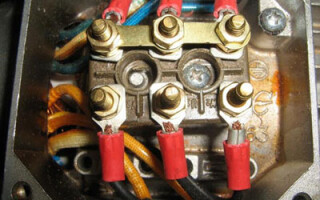

The design of most electric motors allows switching from one connection scheme to another.For this, the beginnings and ends of the windings are displayed on the terminal so that by simply changing the position of the overlays, it is possible to make a “triangle” from a “star” and vice versa.

The owner of the electric motor himself can choose what he needs - a soft start with small starting currents and smooth operation or the greatest power developed by the engine. If you need both, you can switch automatically using powerful contactors.

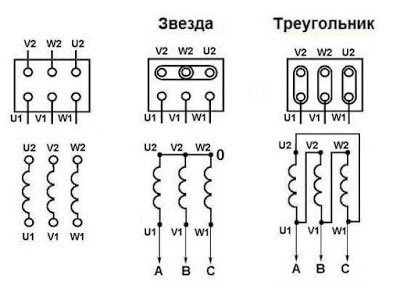

When the start button SB2 is pressed, the electric motor is turned on according to the "star" scheme. The KM3 contactor is pulled up, its contacts close the outputs of the motor windings on one side. The opposite conclusions are connected to the network, each to its own phase through the KM1 contacts. When this contactor is turned on, three-phase voltage is applied to the windings and the rotor of the electric motor is driven. After some time set on the KT1 relay, the KM3 coil switches, it is de-energized, the KM2 contactor turns on, switching the windings into a “triangle”.

Switching occurs after the engine has gained speed. This moment can be controlled by the speed sensor, but in practice everything is easier. Switching is controlled time relay - after 5-7 seconds, it is considered that the starting processes are completed, and you can turn on the engine in maximum power mode. It is not worth delaying this moment, since prolonged operation with an excess of the permissible load for the "star" can lead to the failure of the electric drive.

When implementing this mode, remember the following:

- The starting torque of a motor with star windings is significantly lower than the value of this characteristic of an electric motor with a delta connection, so starting an electric motor with difficult starting conditions in this way is not always possible. It just won't come into rotation. Such cases include electrically driven pumps operating with back pressure, etc. Similar problems are solved with the help of motors with a phase rotor, smoothly increasing the excitation current at start-up. Star start is successfully used when working with centrifugal pumps operating on a closed valve, in case of fan loads on the motor shaft, etc.

- The motor windings must withstand the line voltage of the network. It is important not to confuse D/Y 220/380 volt motors (usually low-power asynchronous motors up to 4 kW) and D/Y 380/660 volt motors (usually 4 kW and above). The 660 volt network is practically not used anywhere, but only electric motors with this rated voltage can be used for star-delta switching. A 220/380 drive in a three-phase network is switched on only by a "star". They cannot be used in the switching scheme.

- A pause must be maintained between turning off the "star" contactor and turning on the "triangular" contactor in order to avoid overlays. But it is impossible to increase it beyond measure in order to prevent the electric motor from stopping. When making a circuit yourself, you may need to select it experimentally.

The reverse switch is also applied. It makes sense if a powerful engine is temporarily running with a small load.At the same time, its power factor is low, because the active power consumption is determined by the load level of the electric motor. Reactive, on the other hand, is mainly determined by the inductance of the windings, which does not depend on the load on the shaft. To improve the ratio of consumed active and reactive power, you can switch the windings to the "star" circuit. This can also be done manually or automatically.

The switching circuit can be assembled on discrete elements - time relays, contactors (starters), etc. Ready-made technical solutions are also produced that combine the automatic switching circuit in one housing. It is only necessary to connect an electric motor and power from a three-phase network to the output terminals. Such devices may have different names, for example, "starting time relay", etc.

Turning on the motor windings according to different schemes has its advantages and disadvantages. The basis of competent operation is the knowledge of all the pros and cons. Then the engine will last a long time, bringing maximum effect.

Similar articles: