An electrical unit with two, three or more windings is statically installed in the power grid. The power transformer changes alternating voltage and current without frequency deviation. The converter used in secondary power supplies is called a step-down device. Step-up structures increase voltage, are used in high-voltage power lines with high power, bandwidth and capacitance.

Content

Application area

The set of installations designed to generate electricity includes power transformers. Power plants use the energy of an atom, organic, solid or liquid fuel, run on gas or use the power of a water stream, but substation output converters are necessary for the normal functioning of consumer and production lines.

The units are installed in networks of industrial facilities, rural enterprises, defense complexes, oil and gas developments. The direct purpose of a power transformer - to lower and increase voltage and current - is used for the operation of transport, housing, retail infrastructure, network distribution facilities.

Main parts and systems

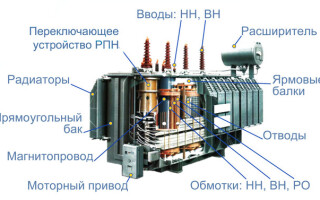

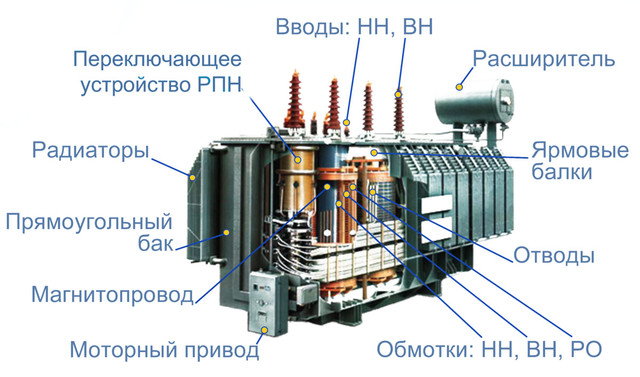

The supply voltage and load are applied to the inputs, which are located on the inner or outer terminal block. The contact is fixed with bolts or special connectors. In oil units, the inlets are arranged outside on the sides of the tank or on the cover of the removable housing.

Transmission from the internal windings goes to flexible dampers or threaded studs made of non-ferrous metals. Power transformers and their cases are insulated from the studs with a porcelain or plastic layer. Gaps are eliminated by gaskets made of a material resistant to oils and synthetic fluids.

The coolers reduce the temperature of the oil from the upper area of the tank and transfer it to the side lower layer. The cooling device of the power oil transformer is represented by:

- an external circuit that removes heat from the carrier;

- internal circuit heating oil.

Coolers are of different types:

- radiators - a set of flat channels with welding at the end, located in plates for communication between the lower and upper collectors;

- corrugated tanks - placed in low- and medium-power units, they are both a container for lowering the temperature and a working tank with a folded surface of the walls and a bottom box;

- fans - they are equipped with large transformer modules for forced cooling of the flow;

- heat exchangers - used in large units to move synthetic fluids using a pump, becausethe organization of natural circulation requires a lot of space;

- water-oil installations - tubular heat exchangers according to classical technology;

- circulating pumps are sealed constructions with full submersion of the engine in the absence of stuffing box gaskets.

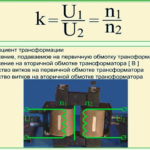

Equipment for voltage transformation is supplied with control devices to change the number of working turns. The voltage on the secondary winding is modified using the switch for the number of coils or set by bolting when choosing the location of the jumpers. This is how the leads of a grounded or de-energized transformer are connected. Regulating modules convert voltage in small ranges.

Depending on the conditions, the switches for the number of spirals are divided into types:

- devices operating when the load is off;

- elements that function when the secondary winding is shorted to resistance.

Attachment

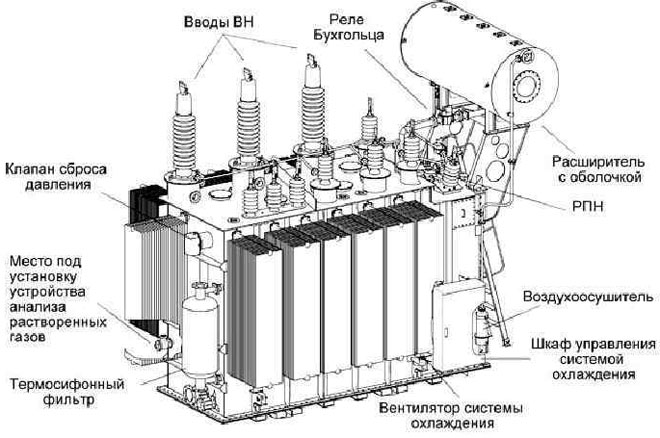

The gas relay is located in the connecting tube between the expansion and working tanks. The device prevents the decomposition of insulating organics, oils during overheating and minor damage to the system. The device reacts to gas formation in case of malfunctions, gives an alarm signal or completely turns off the system in the event of a short circuit or a dangerous drop in the liquid level.

Thermocouples are placed at the top of the tank in pockets to measure the temperature. They work on the principle of mathematical calculation to identify the most heated part of the unit. Modern sensors are based on fiber optic technology.

The continuous regeneration unit is used to restore and purify the oil. As a result of work, slag is formed in the mass, air enters it.Regeneration devices are of two types:

- thermosyphon modules, using the natural movement of the heated layers upwards and passing through the filter, the subsequent lowering of the cooled streams to the bottom of the tank;

- adsorption quality units forcibly pump the mass through the filters with a pump, are located separately on the foundation, and are used in the circuits of large converters.

The oil protection modules are an open-type expansion tank. The air above the mass surface is passed through silica gel desiccants. The adsorbent at maximum humidity turns pink, which serves as a signal to replace it.

An oil seal is installed at the top of the expander. This is a device for reducing air humidity, operating on transformer dry oil. The module is connected to the expansion tank with a pipe. At the top, a container is welded with internal separation in the form of several walls in the form of a labyrinth. Air is passed through the oil, gives off moisture, then is cleaned with silica gel and enters the expander.

Control devices

The pressure relief device prevents an emergency pressure surge due to a short circuit or strong oil decomposition and is provided in the design of powerful units in accordance with GOST 11677-1975. The device is made in the form of a discharge pipe, located at an angle to the transformer cover. At the end is a sealed membrane that can instantly unfold and let the exhaust through.

In addition, other modules are installed in the transformer:

- Oil level sensors in the tank, equipped with a dial or made in the form of a glass tube of communicating containers, are placed at the end of the expander.

- Built-in transformers are arranged inside the unit or near the grounding sleeve on the side of the feed-through insulators or on low-voltage busbars. In this case, there is no need for a large number of individual converters in a substation with internal and external insulation.

- The detector of combustible impurities and gases detects hydrogen in the oil mass and squeezes it out through the membrane. The device indicates the initial degree of gas formation before the concentrated mixture causes the control relay to operate.

- The flow meter monitors oil losses in substations operating on the principle of forced temperature reduction. The device measures the head difference and determines the pressure on both sides of the obstacle in the flow. In water-cooled units, flow meters read the moisture consumption. The elements are equipped with an alarm in case of an accident and a dial for determining indicators.

Principle of operation and modes of operation

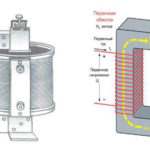

A simple transformer is equipped with a core of permalloy, ferrite and two windings. The magnetic circuit includes a set of tape, plate or molded elements. It moves the magnetic flux that occurs under the action of electricity. The principle of operation of a power transformer is to convert the indicators of current and voltage using induction, while the frequency and shape of the graph of the movement of charged particles remain constant.

In step-up transformers, the circuit provides for an increased voltage on the secondary winding compared to the primary coil. In step-down units, the input voltage is higher than the output. The core with spiral turns is located in a container with oil.

When the alternating current is turned on, an alternating magnetic field is formed on the primary spiral. It closes on the core and affects the secondary circuit. An electromotive force is generated which is transmitted to the connected loads at the output of the transformer. The station operates in three modes:

- Idling is characterized by the open state of the secondary coil and the absence of current inside the windings. No-load electricity flows in the primary coil, which is 2-5% of the nominal value.

- Work under load takes place with the connection of power and consumers. Power transformers show energy in two windings, work in such regulations is common for the unit.

- A short circuit in which the resistance on the secondary coil remains the only load. The mode allows you to identify losses for heating the core windings.

Idle mode

The electricity in the primary coil is equal to the value of the alternating magnetizing current, the secondary current shows zero values. The electromotive force of the initial coil in the case of a ferromagnetic tip completely replaces the source voltage, there are no load currents. Idle operation detects instantaneous turn-on losses and eddy currents, determines reactive power compensation to maintain the required output voltage.

In a unit without a ferromagnetic conductor, there are no losses due to a change in the magnetic field. The no-load current is proportional to the resistance of the primary winding. The ability to resist the passage of charged electrons is transformed by changing the frequency of the current and the size of the induction.

Short circuit operation

A small alternating voltage is applied to the primary coil, the outputs of the secondary coil are short-circuited.The input voltage indicators are selected so that the short-circuit current corresponds to the calculated or nominal value of the unit. The size of the short circuit voltage determines the losses in the coils of the transformer and the cost of resisting the material of the conductor. Part of the direct current overcomes the resistance and is converted into thermal energy, the core is heated.

Short circuit voltage is calculated as a percentage of the nominal value. The parameter obtained during operation in this mode is an important characteristic of the unit. Multiplying it by the short-circuit current gives the power loss.

Work mode

When a load is connected in the secondary circuit, particles move, causing a magnetic flux in the conductor. It is directed away from the flow produced by the primary coil. In the primary winding, there is a disagreement between the electromotive force of induction and the power source. The current in the initial spiral increases until the time when the magnetic field does not acquire its original value.

The magnetic flux of the induction vector characterizes the passage of the field through the selected surface and is determined by the time integral of the instantaneous force index in the primary coil. The exponent is 90˚ out of phase with respect to the driving force. The induced emf in the secondary circuit coincides in shape and phase with that in the primary coil.

Types and types of transformers

Power units are used in the case of converting high-voltage current and high power, they are not used to measure network performance.The installation is justified in case of a difference between the voltage in the network of the energy producer and the circuit going to the consumer. Depending on the number of phases, stations can be classified as single-coil units or multi-winding units.

A single-phase power converter is installed statically, it is characterized by windings connected by mutual induction, located motionless. The core is made in the form of a closed frame, there are lower, upper yoke and side rods, where the spirals are located. Coils and a magnetic core act as active elements.

The windings on the rods are in established combinations according to the number and shape of the turns or are arranged in a concentric order. The most common and often used cylindrical wrapping. The structural elements of the unit fix the parts of the station, isolate the passages between the coils, cool the parts and prevent breakdowns. Longitudinal insulation covers individual turns or their combinations on the core. Primary dielectrics are used to prevent transition between ground and windings.

In the schemes of three-phase electricity networks, two-winding and three-winding installations are installed to evenly distribute the load between the inputs and outputs, or replacement devices for one phase. Oil-cooled transformers contain a magnetic circuit with windings that are located in a tank with a substance.

The windings are arranged on a common conductor, while primary and secondary circuits are provided that interact due to the appearance of a common field, current or polarization when charged electrons move in a magnetic medium. This total induction makes it difficult to determine plant performance, high and low voltage.A transformer substitution plan is used, in which the windings interact not in a magnetic, but in an electrical environment.

The principle of equivalence of the action of dissipative flows to the work of the resistances of inductive coils passing current is applied. There are spirals with active induction resistance. The second type is magnetically bonded wrappings that transmit particles without scattering fluxes with minimal obstructive properties.

Similar articles: