An electric capacitor is one of the elements of the electrical circuit of any electronic device, the main function of which is to store energy and then return it back to the circuit. The industry offers a wide variety of capacitors, differing in types, capacities, sizes, applications.

The principle of operation and characteristics of capacitors

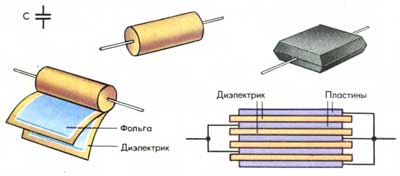

The device of the capacitor consists of two metal plates-plates separated by a thin layer of dielectric. The ratio of the sizes and arrangement of the plates and the characteristic of the dielectric material determines the capacitance index.

The design development of any type of capacitor is aimed at obtaining the maximum capacitance based on the minimum dimensions to save space on the printed circuit board of the device. One of the most popular forms in appearance is in the form of a barrel, inside which metal plates are twisted with a dielectric between them.The first capacitor, invented in the city of Leiden (Netherlands) in 1745, was called the "Leiden jar".

The principle of operation of the component is the ability to charge and discharge. Charging is possible due to the presence of the plates at a small distance from each other. Nearby charges, separated by a dielectric, are attracted to each other and linger on the plates, and the capacitor itself thus stores energy. After disconnecting the power source, the component is ready for the return of energy in the circuit, the discharge.

Parameters and properties that determine performance, quality and durability of work:

- electrical capacity;

- specific capacity;

- allowable deviation;

- electrical strength;

- own inductance;

- dielectric absorption;

- losses;

- stability;

- reliability.

The ability to store charge determines the capacitance of a capacitor. When calculating capacity, you need to know:

- cover area;

- distance between plates;

- dielectric constant of the dielectric material.

To increase the capacitance, it is necessary to increase the area of the plates, reduce the distance between them, and use a dielectric whose material has a high dielectric constant.

Farad (F) is used to denote capacitance - a unit of measurement that got its name in honor of the English physicist Michael Faraday. However, 1 Farad is too large. For example, the capacity of our planet is less than 1 farad. In radio electronics, smaller values are used: microfarad (µF, a millionth of a farad) and picofarad (pF, a millionth of a microfarad).

The specific capacitance is calculated from the ratio of the capacitance to the mass (volume) of the dielectric.This indicator is influenced by geometric dimensions, and an increase in specific capacitance is achieved by reducing the volume of the dielectric, but this increases the risk of breakdown.

The permissible deviation of the passport value of the capacity from the actual one determines the accuracy class. According to GOST, there are 5 accuracy classes that determine future use. Components of the highest accuracy class are used in high-responsibility circuits.

Dielectric strength determines the ability to hold a charge and maintain working properties. The charges remaining on the plates tend to each other, acting on the dielectric. Electrical strength is an important property of a capacitor, which determines the duration of its use. In the event of improper operation, a breakdown of the dielectric will occur and the component will fail.

Self-inductance is taken into account in AC circuits with inductors. For DC circuits, it is not taken into account.

Dielectric absorption - the appearance of voltage on the plates during rapid discharge. The absorption phenomenon is taken into account for the safe operation of high-voltage electrical devices, since in the event of a short circuit, there is danger to life.

The losses are due to the low current transmission of the dielectric. When operating components of electronic devices in different temperature conditions and different humidity, the quality factor of losses has an influence. It is also affected by the operating frequency. At low frequencies, losses in the dielectric affect, at high frequencies - in the metal.

Stability is a capacitor parameter that is also affected by the ambient temperature.Its effects are divided into reversible, characterized by a temperature coefficient, and irreversible, characterized by a coefficient of temperature instability.

The reliability of the capacitor primarily depends on the operating conditions. Analysis of breakdowns suggests that in 80% of cases breakdown is the cause of failure.

Depending on the purpose, type and field of application, the sizes of capacitors also differ. The smallest and smallest, ranging in size from a few millimeters to several centimeters, are used in electronics, while the largest ones are used in industry.

Purpose

The property of storing and releasing energy has determined the widespread use of capacitors in modern electronics. Along with resistors and transistors, they are the basis of electrical engineering. There is not a single modern device where they would not be used in some capacity.

Their ability to charge and discharge, together with an inductance having the same properties, is actively used in radio and television technology. An oscillatory circuit of a capacitor and inductance is the basis for transmitting and receiving signals. Changing the capacitance of the capacitor allows you to change the frequency of the oscillatory circuit. For example, radio stations can transmit on their own frequencies, and radios can connect to those frequencies.

An important function is the smoothing of AC ripples. Any electronic device powered by AC power needs filtering electrical capacitors to produce good quality DC.

The mechanism of charging and discharging is actively used in photographic equipment.All modern cameras use a flash for shooting, which is realized due to the fast discharge property. In this area, it is unprofitable to use batteries that can store energy well, but slowly release it. And capacitors, on the contrary, instantly release all the stored energy, which is enough for a bright flash.

The ability to generate high-power pulses by capacitors is used in radar and the creation of lasers.

Capacitors perform the role of spark-extinguishing contacts in telegraphy and telephony, as well as telemechanics and automation, where switching of highly loaded relays is necessary.

Voltage regulation of long power lines is carried out through the use of compensating tanks.

Modern capacitors, due to their capabilities, are used not only in the field of radio electronics. They are used in metalworking, mining, coal industry.

Main varieties

Due to the variety of applications and operating conditions of electronic devices, there is a wide variety of components that differ in types and characteristics. The main division is by class and by the type of dielectric used.

Types of capacitors, divided by class:

- with constant capacity;

- with variable capacity;

- tuning.

Constant capacitance components are used in every electronic device.

To change the capacitance and circuit parameters, for example, the frequency in oscillatory circuits, capacitors with variable capacitance are used.In their device, they have several sections of metal movable plates, which ensures the durability of their work.

Trimmer capacitors are used for one-time adjustment of equipment. They are available in various capacitance ratings (from a few picofarads to several hundred picofarads) and are rated for voltages up to 60 volts. Without their use, it is impossible to fine-tune the equipment.

Types of capacitors, divided by the type of dielectric:

- with ceramic dielectric;

- with film dielectric;

- electrolytic;

- ionistors.

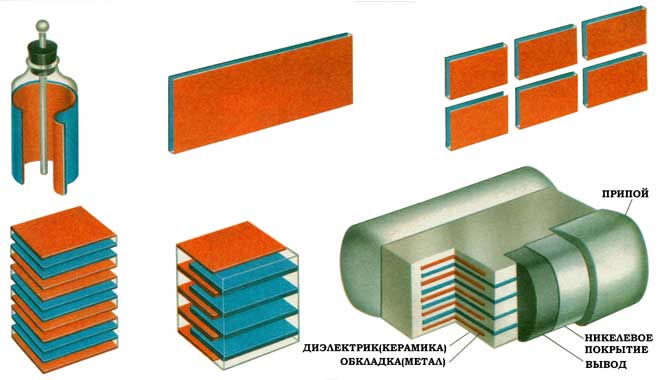

Ceramic ones are made in the form of a small plate of ceramic material, on which metal leads are sprayed. Such capacitors have different properties and are used for both high-voltage and low-voltage circuits.

For low-voltage circuits, multilayer small-sized components in epoxy resin or plastic cases with a capacity from tens of picofarads to units of microfarads are most often used. They are used in high-frequency circuits of radio-electronic equipment and can operate in severe climatic conditions.

For high-voltage circuits, larger ceramic capacitors are made with capacities from tens of picofarads to thousands of picofarads. They are used in impulse circuits and voltage conversion equipment.

Film dielectric is of different types. The most common of them is lavsan, which has high strength. Less common is polypropylene dielectric, which has lower losses and is used in high voltage circuits, such as sound amplification circuits and medium frequency circuits.

A separate type of film capacitors is starting, which are used at the time of starting the engines and, due to their high capacitance and special dielectric material, reduce the load on the electric motor. They are characterized by high operating voltage and electrical reactive power.

Electrolytic capacitors are made in a classic design. The body is made of aluminum, inside are rolled metal plates. Metal oxide is chemically deposited on one plate, and a liquid or solid electrolyte is deposited on the second, forming a dielectric. Thanks to such a device, electrolytic capacitors have a large capacity, but the peculiarity of their use over time is its change.

Unlike ceramic and film capacitors, electrolytic capacitors have polarity. They, in turn, are divided into non-polar, devoid of this drawback, radial, miniature, axial. The scope of their application is traditional computer and modern microcomputer technology.

A special type that has appeared relatively recently are ionistors. In their design, they are similar to electrolytic capacitors, but they are distinguished by a large capacity (up to units of Farad). However, their use is limited to a small maximum voltage of a few volts. Supercapacitors are used to store memory: if the battery in a mobile phone or miniature computer runs out, the stored information will not be irretrievably lost.

In addition to the components in the output version, which appeared a long time ago and which were traditionally used, modern components are produced in the SMD version, or, as it is also called, for surface mounting. For example, ceramic can be produced in various sizes of cases, from the smallest (1 mm by 0.5 mm) to the largest (5.7 mm by 5 mm), and with corresponding voltages from tens of volts to hundreds.

Electrolytic capacitors can also be produced in surface mount packages. These can be standard aluminum electrolytic capacitors, or they can be tantalum capacitors, which look a little like ceramic ones, but differ from them in higher capacitance and low losses. They can be both pinned and non-pinned SMD.

A feature of tantalum capacitors is a long life and minimal losses with a slightly lower capacitance limit, but at the same time they are distinguished by a high price. They are used in high responsibility circuits where high capacitance is required.

Similar articles: