During the construction or reconstruction of a house, as well as the modernization of electrical networks, it becomes necessary to bring a new electrical cable to the house. For such a connection, which is carried out from a power line support, a self-supporting insulated cable (SIP) is most often used. Consider the stages of installation and connection of the cable from the support to the house, wire connection methods on a support and frequent mistakes when performing this type of electrical work.

Content

Installation of SIP cable from the pole to the house

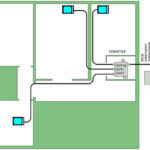

Correct installation SIP cable begins with fixing and connecting it to a support, having previously measured the distance from the nearest support to the connected object.The fact is that the distance from the support to the fixing point on the building should not exceed 25 meters, otherwise it is necessary to install an additional electric pole.

It is also important to choose the right section of the SIP electric cable. The most common type of self-supporting wire used in residential construction is 4×16 SIP.

Fixing the wire to the pole

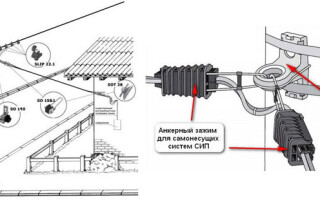

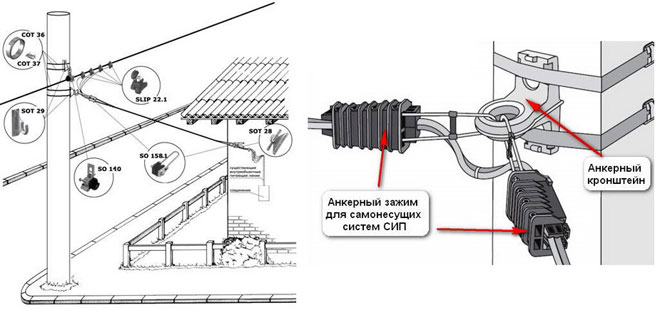

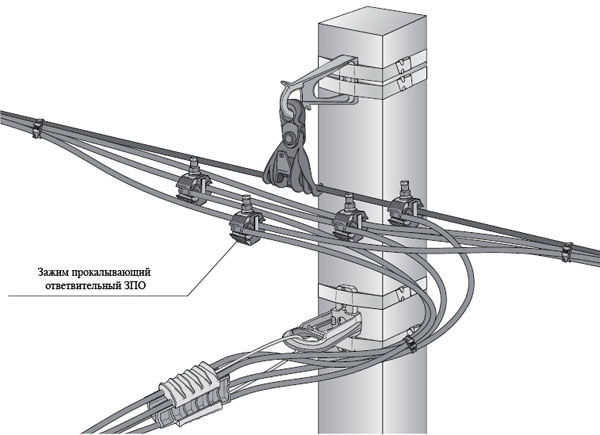

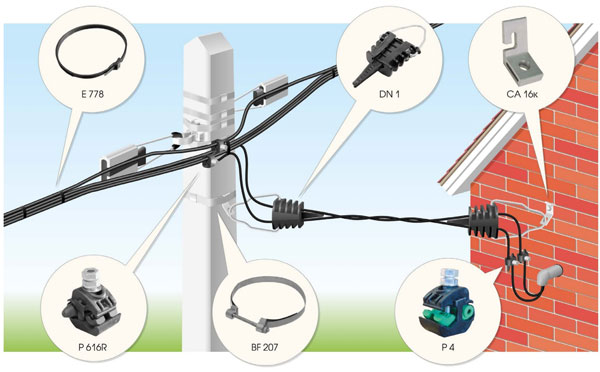

The first thing to do with the wire is to correctly and securely fix it to the power line support. Since it is impossible to drill holes in the electric pole, galvanized steel tape, yokes (reinforced fasteners for connecting the tape and tightening), as well as special brackets are used to fasten the SIP.

In order to fix the bracket on the pole, the tape is wrapped in the form of a bandage in two rows around the pole, the bracket is mounted between them and pulled together, fixing the tape with paper clips. After that, they take the anchor tension clamp, pass the cable through it and fix it on the bracket.

Lead from the pole to the house

The next operation is to bring the cable to the house, tension it, fix it and connect it. To fix the SIP wire on the facade of the building, a similar bracket is used, but fixing it with anchor bolts. According to SNiP, the height of fixing the wire on the facade of a residential building should be 2.75 meters, therefore, if this parameter does not correspond to the design features of the house, then the input must be made through its roof. Anchors are selected based on the material of the load-bearing walls to which the bracket and wire will be attached. To fix the wire on the bracket, an anchor clamp for the SIP wire is used, the same as used on the support.

It is important to know that the input cable from the power line to the connection point (electrical panel) should not have breaks and connections, but should be solid.

An important step is also the correct tension of the cable, since excessive sagging adversely affects the durability and reliability of the mounted cable. wires.

CIP wire tension

The tension of the self-supporting insulated wire is carried out using a manual hoist (winch), which has a special gripping mechanism for the carrier core or the entire SIP cable. When carrying out this work, the main thing is not to overdo it and clearly calculate the applied force, best of all using a dynamometer. When working on a project, the cable tension will be indicated in it. But if there is no such documentation, then you can use a special mounting table. Such a table will indicate the value of the tension force for various ambient temperature conditions and the length of the sag.

It is very important, after all, to use tables and measure the tension of the wire, and not to carry out installation “by eye”. Since in winter, under adverse conditions (snowfall, ice), the cable will not break, and moisture will not flow down the cable into the building, and will not get into the electrical panel.

Ways to connect the wire on the pole

To connect the SIP wire to current-carrying power lines on a support, several options are used, depending on the power line cable.

For insulated cable lines, special piercing clamps are most often used, which are available in a wide range for various sections and types of insulation.Some clamps can be used without removing the voltage from the line: in their design, the shear head is insulated, which allows you to safely connect the SIP to the power line. At the same time, the design of the piercing clamps does not allow them to be reused, so everything must be correctly calculated, without the right to make a mistake.

But for bare conductors, special clamps are used that have contacts with a smooth surface and do not have piercing elements.

When connecting a house to a power line, it is better to coordinate all actions with the power supply organization. Such organizations may have their own requirements for making connections and materials used.

Some "masters" lower the SIP along the pole and lay it underground to the house. But it is important to understand that the self-supporting SIP cable is not intended for such installation, since it does not have special protection against harmful effects and armor against mechanical damage, as a result of which it is intended only for laying through the air.

Connection to the machine and counter

Entering the house and laying the cable to the electrical panel is carried out in special metal cable channels, corrugation or pipes. Usually, a regular steel pipe is used for this. At the same time, it is important that unprotected conductors of electrical wiring are inaccessible to touch (including accidental) with places where people often stay or pass. Also, according to clause 2.1.79 of the Electrical Installation Code, it is recommended to mount the cable in the pipe so that water does not accumulate in the passage and does not penetrate inside the building, especially to electrical installations.

In the electrical panel, the cable is connected to the inlet switch, with preliminary crimping of the conductors with pin lugs made of aluminum and copper alloy, and from the switch, to the inlet circuit breaker and then to other protective devices (RCD, differential circuit breakers and circuit breakers).

Sometimes, branches from the VVGng copper cable are connected to the SIP cable using the same piercing clamps, and it is already connected to a switch in the electrical panel or directly to the introductory machine (depending on the cable section).

Possible installation errors

When installing the entrance to the house using the SIP cable, difficulties may arise, and in order to avoid mistakes, the most common of them are listed below:

- Weak tension: no dynamometer was used during tension, and installation was carried out “by eye”. This error can lead to an increase in the load on the cable, especially in winter, and its breakage.

- Strong tension: also negatively affects the cable, especially its insulation.

- An attempt to reuse the piercing clips: they are disposable, as the head breaks off and re-assembly is not possible.

- Insulation damage during work: it is important to use a one-piece cable, damage to the insulation can lead to a short circuit or electric shock.

- Clamps are not completely fixed: the conductors must be correctly and securely fixed in the clamps and not hang out in them. A bad clamp leads to poor contact, sparking and damage to the cable.

Security measures

In any electrical work, the very first and most important thing is to follow the rules of electrical safety.

- It is impossible to carry out work in high humidity, fog or during rain, as well as at night or at dusk;

- It is necessary to use only certified and reliable tools, cable and fasteners;

- Do not use a damaged cable;

- Do not use fasteners and clamps that are not designed for the type of cable used;

- Work is carried out strictly with the use of overalls;

- Live wires are insulated with special overlays;

- Work at height should be carried out by professional installers using machines and mechanisms designed to work near power lines and having the appropriate work permit.