When carrying out electrical work, it often becomes necessary to lay electrical wiring in an open way. To ensure the protection of the electrical cable from mechanical influences, precipitation and other factors, to make a neat and aesthetic electrical installation of power or low-current networks, a corrugated tube or, as it is also called, a corrugation, is used.

Content

What is corrugation and where is it used

Wiring corrugation - this is a corrugated pipe for laying an electrical cable in order to protect it or protect structures. The laying of an electrical cable in corrugated tubes is used in various situations with open or hidden electrical wiring.

Hidden gasket

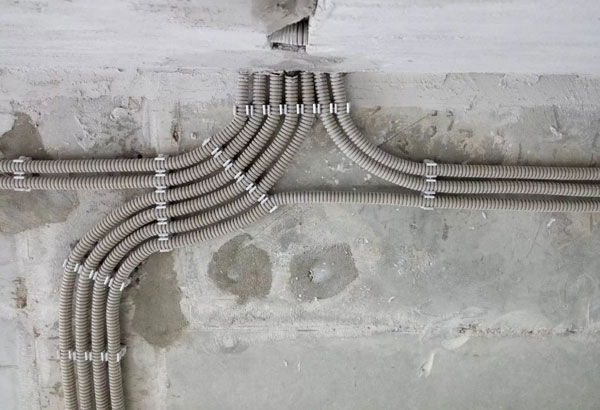

Hidden gasket - this is the installation of electrical wiring inside the structures of walls, floors and ceilings, behind finishing materials. It is conditionally divided into the following types of installation:

Laying inside non-combustible structures is produced in wall and ceiling strobes, in floor screed or simultaneously with the installation of load-bearing structures (e.g. when concreting). In this case, corrugation is used for ease of installation, protection against cable crushing and the possibility of replacing electrical wiring without disturbing the finishing material, chasing or dismantling wall, ceiling or floor structures. When laying a corrugated cable inside structures made of non-combustible materials, the PUE allows the use of any type of corrugated tubes.

Laying behind finishing materials or in false spaces has purposes similar to laying in non-combustible structures (protection against mechanical damage, the possibility of replacing the wiring if necessary), but with the fulfillment of the installation requirements, as when laying on combustible materials. The fact is that finishing materials often contribute to combustion, therefore, for such an installation, the requirements are quite strict. It is important to use flame retardant or metal corrugations for this installation.

underground laying carried out in the production of works on the improvement of territories for the wiring of electrical power lines to lighting fixtures and various equipment (sprinkler pumps, gate and door opening systems), when laying low-voltage networks for security systems or telephone lines, and in other situations. The main requirement for such laying of corrugations with an electric cable is water tightness and high resistance to mechanical deformation (rigidity).

open laying

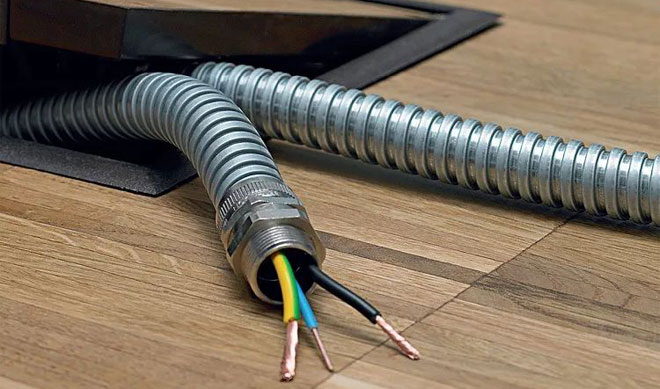

open laying carried out on load-bearing and enclosing structures, finishing materials and during installation on the street to the facades of buildings or by air.

Laying on combustible materials of structures involves the installation of electrical wiring in the corrugation to ceilings and walls with a combustible finish or made of wood, plastic and other materials that promote combustion. For reasons of fire safety, non-flammable (metal) corrugated tubes. With such an installation, according to the PUE, it is forbidden to use plastic corrugation made of self-extinguishing and non-flammable materials.

Laying on non-combustible structures and materials is carried out by any corrugated plastic tubes that do not spread combustion. It is possible to use metal corrugations to improve the aesthetics of installation or when used in special conditions (aggressive environments, the likelihood of mechanical damage).

Laying outside buildings and structures used for lighting installation or laying power and low-voltage networks for various purposes along the facades of buildings and fences, as well as through the air between buildings. The corrugation used in this case should also not spread combustion and should be resistant to precipitation, ultraviolet radiation and be durable.

Cable laying in fire or explosion hazardous areas carried out exclusively with the use of metal corrugated pipes in combination with an electric cable that does not spread flame.

Varieties according to the material of manufacture

Corrugated tubes for electrical cables are made of metal or special plastic. Corrugations from the following materials are widely used in construction:

Polyvinyl chloride (PVC) - lightweight material with self-extinguishing properties. Corrugations made of such material are made in gray. PVC corrugations for cables are used in dry enclosed spaces, as they are sensitive to ultraviolet radiation and are not water resistant. Received the greatest distribution in connection with availability (low price) and versatility of application.

Polypropylene (PPR) – material that does not support or propagate combustion, is resistant to ultraviolet radiation. Corrugations made of such material are waterproof and are used when laying networks outdoors or in rooms with high humidity. By color, such corrugations are blue.

Low-pressure polyethylene (HDPE) - moisture resistant material. Such tubes are also used in wet rooms or outdoors. HDPE is a combustible material, so it is not used in wooden rooms. It is allowed to use HDPE corrugations in screeds or in structures made of non-combustible materials. Available in orange or black.

Stainless steel - the most resistant and expensive material for the manufacture of corrugated tubes. Resistant when used in aggressive environments and perfectly protects the cable from mechanical damage (e.g. against rodents or accidental damage during construction and repair work). They are used both indoors for combustible and non-combustible materials, inside structures, and outdoors with underground or air cable laying.

Polyamide (PA) - a very flexible material that is resistant to mechanical and chemical influences. Has a wide operating temperature range-60 to +150 degrees Celsius). Corrugated tubes made of such material do not spread combustion and can be used both inside buildings and outside. Produced in dark grey.

How to choose corrugation for wiring

To select a corrugation, it is necessary to know the diameter of the electrical cable and the conditions under which the corrugated pipe will be laid. When choosing a diameter, the following recommendations should be considered:

- corrugations with a diameter of 16 mm are used for lighting cables, switches or signal lines;

- corrugations with a diameter of 20-25 mm are used for sockets or for laying a coaxial cable;

- for connection to junction boxes, depending on the cable section, from 25 to 32 mm;

- for laying the cable to electrical panels, a corrugation with a diameter of 32 mm should be used;

- for large cable diameters, corrugations with a diameter of 40 mm and above are used.

An indicative table of the dependence of the diameter of the corrugation on the cross section and the number of cores of the NYM or VVG electric cable is presented below:

| Cross section of electric cable, mm² | Number of cores, pcs | Corrugation outer diameter, mm |

|---|---|---|

| 1,5 | 2/3/4/5 | 16/16/20/20 |

| 2,5 | 2/3/4/5 | 16/16/20/25 |

| 4 | 2/3/4/5 | 20/20/25/25 |

| 6 | 2/3/4/5 | 20/25/32/32 |

| 10 | 2/3/4/5 | 25/32/32/40 |

| 16 | 2/3/4/5 | 32/32/40/40 |

| 25 | 2/3/4/5 | 32/40/50/50 |

When choosing a corrugation, it is especially important to focus on the conditions in which the corrugated pipe with an electric cable will be installed and operated. Each material is suitable for different installation options. Briefly, you can specify the following materials and the conditions for their use:

- PVC: dry and enclosed spaces;

- PPR: wet rooms, street, underground laying;

- HDPE: wet rooms, street, underground laying;

- Metal: in any conditions;

- PA: in any conditions.

Recommendations for installation work

Inserting the cable into the corrugation

The cable is laid in a corrugated pipe using a special string installed by the manufacturer inside the corrugation. The sequence of work when laying an electric cable in a pipe is as follows:

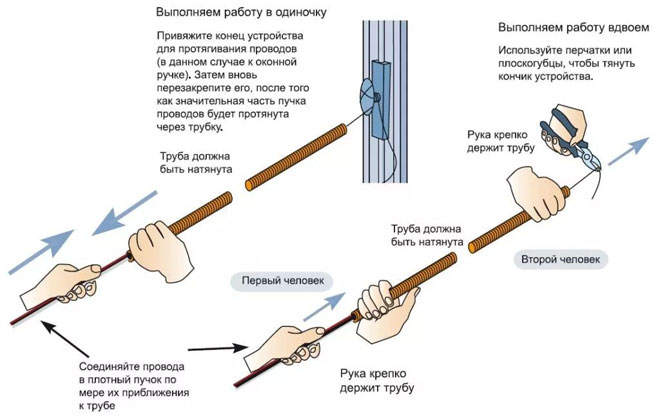

- The corrugated pipe is stretched over a long straight section. In order to tighten the cable inside the corrugation, you need to have a large space for complete unwinding.

- The end of the electric cable is connected to the string, the junction is wrapped with electrical tape for free movement without wire hooks inside the pipe.

- A minimum of two people are required to complete this work. One person holds the corrugated pipe from one end, the second one gently and without jerks pulls out the string with the electric cable.

- After the cable has appeared on the back of the corrugation, it is fixed (e.g. tape) on both sides so that it does not jump into the corrugation again.

Fixing corrugated pipes

When installing a corrugated pipe with an electric cable, a variety of fixing methods are used. The most common of them:

- installation with plastic clips: used for installation on any types of structures;

- installation with dowel-clamps or dowel-studs: used when installing corrugations on concrete and wooden structures;

- installation with plastic ties to a metal cable or frame: used when laying corrugations on the street or in the presence of a metal frame (e.g. in plasterboard ceilings);

- mounting in strobes with subsequent sealing: used in concrete and brick walls, in plaster.

Errors when installing the cable in the corrugation

The most important and common mistake when installing a cable in a corrugation is the incorrect selection of the type of corrugated pipe material based on the operating conditions. In order for the electrical wiring to serve for a long time and reliably, it is necessary to follow the recommendations that are indicated above in this article on choosing the right corrugation for your purposes.

Similar articles: