When planning electrical work in a house or apartment, the question may arise as to which is better: copper or aluminum wiring?

In this article, we will figure out what material should be used for wiring. electric cable in residential premises and consider all the pros and cons of copper and aluminum conductors.

Content

Comparison of aluminum and copper wires by technical specifications

In order to understand the difference between copper and aluminum, you need to consider and compare their technical characteristics.

Conductor properties

The main electrical properties of the material of conductors are their electrical resistivity, thermal conductivity and temperature coefficient of resistance. Mechanical properties include weight, strength, elongation at break and service life under normal operation.

Specific electrical resistance

Specific electrical resistance - this is the ability of a material to resist electric current when it flows through a conductor. This characteristic is calculated by the formula:

Ρ = r⋅S/l,

where l is the length of the conductor, S is the cross-sectional area, r is the resistance.

For comparison:

| Conductor material | Electrical resistivity, Ohm mm²/m |

|---|---|

| Copper | 0,0175 |

| Aluminum | 0,0300 |

As can be seen from this table, copper has a lower resistivity and, accordingly, it heats up less and conducts electric current better.

Thermal conductivity

Thermal conductivity - this is a property of a conductor, which shows the amount of heat that passes per unit time through a layer of matter. For calculation electric cable this characteristic is quite important, since the safe operation of electrical wiring depends on it. The higher the thermal conductivity of the material, the less it heats up and the better it gives off excess heat.

For comparison:

| Conductor material | Thermal conductivity, W/(m K) |

|---|---|

| Copper | 401 |

| Aluminum | 202—236 |

Temperature coefficient of resistance

When different materials are heated, their electrical conductivity changes. The characteristic that shows this change is called the temperature coefficient of resistance (tks). This value is determined using a special TCS meter and the average value of this coefficient is taken.

Note! Temperature coefficient of resistance is the ratio of the relative change in resistance to the change in temperature. Denoted α.

For comparison:

| Conductor material | Temperature coefficient of resistance, 10-3/K |

|---|---|

| Copper | 4,0 |

| Aluminum | 4,3 |

The lower the temperature coefficient of resistance, the greater the stability of the conductor.

Weight and electrical conductivity of the conductor

Copper is much heavier than aluminum. Its density is 8900 kg/m³, and the density of aluminum is 2700 kg/m³. This means that a copper conductor will be 3.4 times heavier than a similarly sized aluminum wire.

It is important to understand that the electrical conductivity of copper is more than 50% higher than that of aluminum and, accordingly, in order for an aluminum conductor to conduct the same current, it must be 50% larger than copper.

Therefore, it is more efficient to use a copper conductor than a cable made of aluminum material.

Elongation at break and strength

An electric cable can operate in various modes and operating conditions, therefore, when choosing a conductor, it is very important to take into account its resistance to mechanical stress. Tensile strength is a characteristic that takes into account the strength of the material and the resistance to breaking load.

For comparison:

| Conductor material | Tensile strength, kg/m² |

|---|---|

| Copper | 27 – 44,9 |

| Aluminum | 8 – 25 |

Based on the analysis of the table, it is clearly seen that copper has a high resistance to mechanical stress and significantly exceeds aluminum in this characteristic.

Life time

The service life of the electrical wiring depends on the operating conditions and the environment.It is generally accepted that the service life of an aluminum cable under normal operating conditions is 20-30 years. At the same time, copper wiring lasts much longer and its service life can reach up to 50 years.

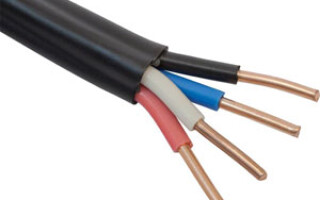

What material for electrical wiring should be chosen for an apartment

In Soviet times, the use of aluminum wiring was common in residential premises. This was due to the fact that in residential buildings there were no high loads on the electrical network due to low power and a small number of electrical appliances. With the development of technology and the emergence of a huge variety of powerful electrical appliances that are used at home, the requirements for quality and materials for electrical cables have increased significantly. In modern realities, the wiring device made of aluminum material is practically not used, since according to the PUE electrical wiring in residential premises should be made of copper!

Interesting fact! Not many people know, but a little earlier, before aluminum wiring, in Stalin's times, copper wiring was used in apartments.

Advantages and disadvantages of aluminum wiring

The main advantages of aluminum electrical wiring are:

- small mass: the density of aluminum is lower and, accordingly, its mass is lower. When laying simple networks with many cables, but light loads, this will be a convenient advantage.

- small price: aluminum is several times cheaper than copper, so products made from this material are also distinguished by a low price.

- Oxidation resistance: in the absence of contact with the environment, it lasts a long time and is not destroyed by oxidation.

The disadvantages of this material include:

- Low electrical conductivity Aluminum has a high resistivity and heats up when an electric current passes through it. Therefore, the PUE prohibits the use of such a cable in home networks with a conductor cross section of less than 16 mm².

- Bad connection - due to oxidative processes and heating / cooling cycles, the junctions of the aluminum cable are gradually destroyed, which can lead to a malfunction of the electrical wiring or a short circuit.

- Brittleness of conductors - such cables break easily when heated, which also very often leads to malfunctions.

Advantages and disadvantages of copper wiring

Copper is approved for use and is widely used for electrical wiring in residential and industrial buildings. In terms of electrical characteristics, it surpasses many materials and is second only to silver.

The advantages of copper cables are:

- High electrical and thermal conductivity - copper has a relatively low resistance and effectively conducts electric current, has a high efficiency, and also does not heat up significantly with the correct cable section.

- Corrosion resistance - copper conductors can work under any operating conditions and environment, serve for a long time and practically do not corrode.

- Resistance to mechanical stress Copper electrical wiring is strong, ductile and flexible.

- Flexibility and ease of installation - copper conductors are very flexible and it is convenient to mount them at different angles and connect them to sockets and switches.

The main disadvantage of copper is its high price. But you need to understand that in the production of such a responsible type of work as wiring, safety and durability are very important. Therefore, despite its cost, copper wiring quickly pays off and, if used correctly, lasts a very long time without repairs and malfunctions.

Is it worth replacing the old aluminum wiring?

This question can be answered with confidence and unequivocally: yes, definitely worth it! The use of old aluminum wiring under the current modern loads on the electrical network is not only inefficient, but also unsafe. Moreover, according to the PUE, aluminum wires cannot be used during installation. house wiring. Therefore, if it is possible to change the electrical wiring, then it should definitely be changed to copper with the correct calculation, section selection and the number of electrical lines.

Electrical work is the case when you can not save on the quality of materials. The safety of people and the correct operation of electrical appliances in the house depend on the correct selection and calculation of materials.

If you still decide to leave the old electrical wiring, then you should redo the shield, limit the power and protect each line from exceeding the load above 16 A (this will allow you not to worry that at some point the wiring will overheat and catch fire).

Although copper wiring is much more expensive than aluminum, it pays off in the long run and does not bring problems to the user.

Similar articles: