"Accuracy - the politeness of kings!" In our time, the relevance of this medieval French aphorism is only growing. To carry out accurate measuring calculations in production and in everyday life, devices based on strain gauges are increasingly being used.

Content

What is strain gauge and what are strain gauges for?

Tensometry (from Latin tensus - stressed) is a method and technique for measuring the stress-strain state of a measured object or structure. The fact is that it is impossible to directly measure the mechanical stress, so the task is to measure the deformation of the object and calculate the stress using special techniques that take into account the physical properties of the material.

The work of strain gauges is based on the strain effect - this is the property of solid materials to change their resistance with various deformations. Strain gauge sensors are devices that measure the elastic deformation of a solid body and convert its value into an electrical signal. This process occurs when the resistance of the sensor conductor changes when it is stretched and compressed. They are the main element in instruments for measuring the deformation of solids (for example, machine parts, structures, buildings).

Device and principle of operation

The basis of the strain gauge is a strain gauge equipped with special contacts fixed on the front of the measuring panel. During the measurement, the sensitive contacts of the panel are in contact with the object. Their deformation occurs, which is measured and converted into an electrical signal transmitted to the processing and display elements of the measured value of the strain gauge.

Depending on the scope of functional use, sensors differ both in types and types of measured quantities. An important factor is the required measurement accuracy. For example, a load cell load cell at the exit from the bakery is absolutely not suitable for electronic pharmaceutical scales, where every hundredth of a gram is important.

Let us consider in more detail the types and types of modern strain gauges.

Torque sensors

Torque sensors are designed to measure torque on rotating parts of systems such as an engine crankshaft or steering column.Torque strain gauges can determine both static and dynamic torque by contact or non-contact (telemetric) method.

Beam, cantilever and edge load cells

These types of transducers are usually made on the basis of a parallelogram design with a built-in bending element for high sensitivity and linearity of measurements. Strain gauges in them are fixed on the sensitive areas of the elastic element of the sensor and are connected according to the full bridge scheme.

Structurally, the beam load cell has special holes for uneven load distribution and detection of compressive and tensile deformations. To obtain the maximum effect, strain gauges are strictly oriented by special marks on the surface of the beam at its thinnest point. Highly accurate and reliable sensors of this type are used to create multi-sensor measuring systems in platform or bunker scales. They have found their application in weighing batchers, packers of loose and liquid products, cable tension meters and other power load meters.

Tensile and Compressive Load Cells

Tensile and compressive load cells are usually S-shaped, made of aluminum and alloyed stainless steel. Designed for bunker scales and batchers with a measurement range of 0.2 to 20 tons. S-shaped tensile and compressive load cells can be used in cable, fabric and fiber machines to control the tensile force of these materials.

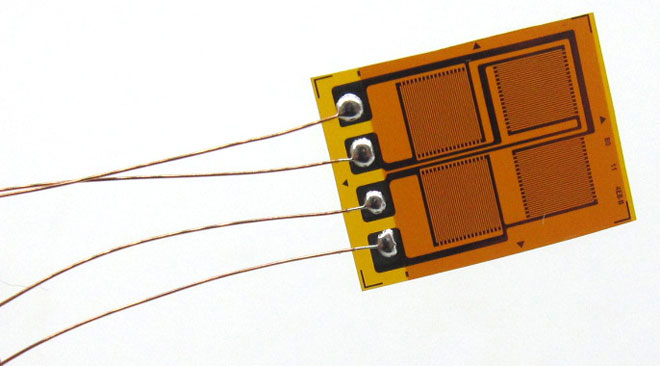

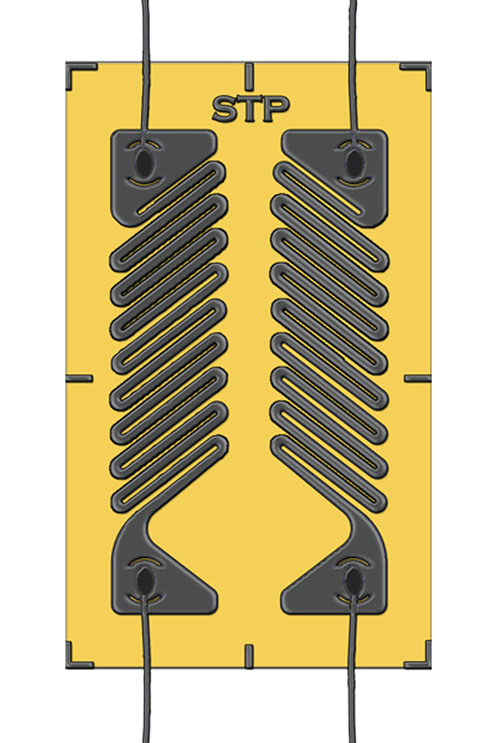

Wire and foil strain gauges

Wire strain gauges are made in the form of a spiral of small-diameter wire and mounted on an elastic element or part under test with glue.They are distinguished by:

- ease of manufacture;

- linear dependence on strain;

- small size and price.

Among the shortcomings, low sensitivity, the influence of temperature and humidity of the environment on the measurement error, the possibility of using only in the field of elastic deformations are noted.

foil strain gauges are currently the most common type of strain gauges due to their high metrological qualities and manufacturability. This became available thanks to the photolithographic technology of their manufacture. Advanced technology makes it possible to obtain single strain gauges with a base of 0.3 mm, specialized strain gauge sockets and chains of strain gauges with a wide operating temperature range from -240 to +1100 ºС, depending on the properties of the measuring grid materials.

Advantages and disadvantages of strain gauges

Strain gauges are widely used due to their properties:

- the possibility of a monolithic connection of the strain gauge with the part under study;

- small thickness of the measuring element, which ensures high measurement accuracy with an error of 1-3%;

- ease of fastening, both on flat and curved surfaces;

- the ability to measure dynamic deformations that change with a frequency of up to 50,000 Hz;

- the possibility of carrying out measurements in difficult environmental conditions in the temperature range from -240 to +1100˚С;

- the possibility of measuring parameters simultaneously at many points of the parts;

- the possibility of measuring the deformation of objects located at large distances from strain gauge systems;

- the ability to measure deformations in moving (rotating) parts.

Of the shortcomings, it should be noted:

- influence of weather conditions (temperature and humidity) on the sensitivity of sensors;

- insignificant changes in the resistance of the measuring elements (about 1%) require the use of signal amplifiers.

- when strain gauges operate in high-temperature or aggressive environments, special measures are required to protect them.

Basic wiring diagrams

Let's consider this using the example of connecting strain gauges to household or industrial scales. A standard load cell for scales has four multi-colored wires: two inputs are power supply (+Ex, -Ex), the other two are measuring outputs (+Sig, -Sig). There are also options with five wires, where an additional wire serves as a screen for all the others. The essence of the operation of a beam-type weight measuring sensor is quite simple. Power is supplied to the inputs, and voltage is removed from the outputs. The voltage value depends on the applied load on the measuring sensor.

If the length of the wires from the weight load cell to the ADC unit is significant, then the resistance of the wires themselves will affect the reading of the scales. In this case, it is advisable to add a feedback circuit that compensates for the voltage drop by correcting the error from the resistance of the wires introduced into the measuring circuit. In this case, the connection diagram will have three pairs of wires: power, measurement and loss compensation.

Application examples for strain gauges

- weighing element.

- measurement of strain forces in the processing of metals by pressure on stamping presses and rolling mills.

- monitoring of stress-strain states of building structures and structures during their erection and operation.

- high-temperature sensors made of heat-resistant alloy steel for metallurgical enterprises.

- with stainless steel elastic element for measurements in chemically aggressive environments.

- for pressure measurement in oil and gas pipelines.

Simplicity, convenience and manufacturability of strain gauges are the main factors for their further active implementation, both in metrological processes and in everyday life as measuring elements of household appliances.

Similar articles: