Temperature is one of the main physical parameters. It is important to measure and control it both in everyday life and in production. There are many special devices for this. The resistance thermometer is one of the most common instruments actively used in science and industry. Today we will tell you what a resistance thermometer is, its advantages and disadvantages, and also understand the various models.

Content

Application area

resistance thermometer is a device designed to measure the temperature of solid, liquid and gaseous media. It is also used for measuring the temperature of bulk solids.

The resistance thermometer has found its place in gas and oil production, metallurgy, energy, housing and communal services and many other industries.

IMPORTANT! Resistance thermometers can be used in both neutral and aggressive environments. This contributes to the spread of the device in the chemical industry.

Note! Thermocouples are also used in industry to measure temperatures, learn more about them from our article about thermocouples.

Types of sensors and their characteristics

Temperature measurement with a resistance thermometer is carried out using one or more resistance sensing elements and connecting wires, which are securely hidden in a protective case.

The classification of the vehicle occurs precisely according to the type of the sensitive element.

Metal resistance thermometer according to GOST 6651-2009

According to GOST 6651-2009 they distinguish a group of metal resistance thermometers, that is, TS, whose sensitive element is a small resistor made of metal wire or film.

Platinum Temperature Meters

Platinum TS are considered the most common among other types, so they are often installed to control important parameters. Temperature measurement range lies from -200 °С to 650 °С. The characteristic is close to a linear function. One of the most common types is Pt100 (Pt - platinum, 100 - means 100 ohms at 0 ° C).

IMPORTANT! The main disadvantage of this device is the high cost due to the use of precious metal in the composition.

Nickel resistance thermometers

Nickel TS are almost never used in production due to the narrow temperature range (from -60 °С to 180 °С) and operational difficulties, however, it should be noted that they have the highest temperature coefficient 0.00617 °C-1.

Previously, such sensors were used in shipbuilding, however, now in this industry they have been replaced by platinum vehicles.

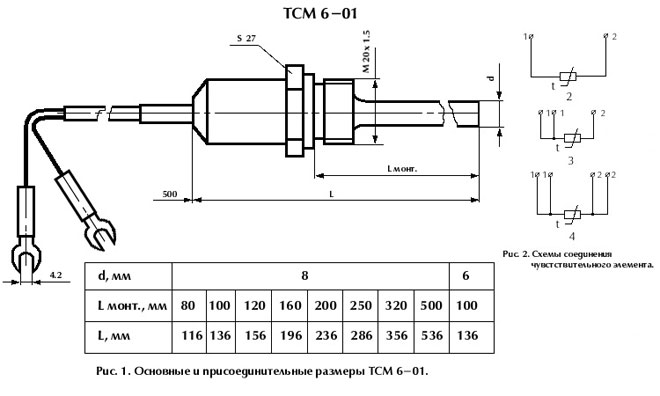

Copper sensors (TCM)

It would seem that the range of use of copper sensors is even narrower than that of nickel ones (only from -50 °С to 170 °С), but, nevertheless, they are the more popular type of vehicle.

The secret is in the cheapness of the device. Copper sensing elements are simple and unpretentious in use, and are also excellent for measuring low temperatures or related parameters, such as the air temperature in the shop.

The service life of such a device is short, however, and the average cost of a copper TS is not too expensive (about 1 thousand rubles).

Thermistors

Thermistors are resistance thermometers whose sensing element is made of a semiconductor. It can be an oxide, a halide, or other substances with amphoteric properties.

The advantage of this device is not only a high temperature coefficient, but also the ability to give any shape to the future product (from a thin tube to a device a few microns long). As a rule, thermistors are designed to measure temperature from -100 °С to +200 °С.

There are two types of thermistors:

- thermistors - have a negative temperature coefficient of resistance, that is, with an increase in temperature, the resistance decreases;

- posistors - have a positive temperature coefficient of resistance, that is, as the temperature increases, the resistance also increases.

Calibration tables for resistance thermometers

Graduation tables are a summary grid by which you can easily determine at what temperature the thermometer will have a certain resistance. Such tables help instrumentation workers to evaluate the value of the measured temperature for a certain resistance value.

Within this table, there are special vehicle designations. You can see them on the top line. The number means the resistance value of the sensor at 0°C, and the letter is the metal from which it is made.

To designate metal, use:

- P or Pt - platinum;

- M - copper;

- N - Nickel.

For example, 50M is a copper RTD, with a resistance of 50 ohms at 0 ° C.

Below is a fragment of the calibration table of thermometers.

| 50M (ohm) | 100M (Ohm) | 50P (Ohm) | 100P (Ohm) | 500P (Ohm) | |

|---|---|---|---|---|---|

| -50 °C | 39.3 | 78.6 | 40.01 | 80.01 | 401.57 |

| 0 °С | 50 | 100 | 50 | 100 | 500 |

| 50 °C | 60.7 | 121.4 | 59.7 | 119.4 | 1193.95 |

| 100 °С | 71.4 | 142.8 | 69.25 | 138.5 | 1385 |

| 150 °С | 82.1 | 164.2 | 78.66 | 157.31 | 1573.15 |

Tolerance class

The tolerance class should not be confused with the concept of accuracy class. With the help of a thermometer, we do not directly measure and see the measurement result, but transfer the resistance value corresponding to the actual temperature to the barriers or secondary devices. That is why a new concept has been introduced.

The tolerance class is the difference between the actual body temperature and the temperature that was obtained during the measurement.

There are 4 classes of TS accuracy (from the most accurate to devices with a greater error):

- AA;

- BUT;

- B;

- FROM.

Here is a fragment of the table of tolerance classes, you can see the full version in GOST 6651-2009.

| Accuracy class | Tolerance, °С | Temperature range, °C | ||

|---|---|---|---|---|

| Copper TS | Platinum TS | Nickel TS | ||

| AA | ±(0.1 + 0.0017 |t|) | - | from -50 °С to +250 °С | - |

| BUT | ±(0.15+0.002 |t|) | from -50 °С to +120 °С | from -100 °С to +450 °С | - |

| AT | ±(0.3 + 0.005 |t|) | from -50 °С to +200 °С | from -195 °С to +650 °С | - |

| FROM | ±(0.6 + 0.01 |t|) | from -180 °С to +200 °С | from -195 °С to +650 °С | -60 °С to +180 °С |

Connection diagram

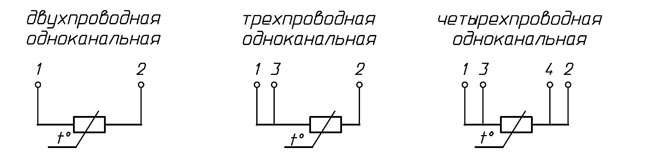

In order to find out the value of resistance, it must be measured. This can be done by including it in the measuring circuit. For this, 3 types of circuits are used, which differ in the number of wires and the achieved measurement accuracy:

- 2-wire circuit. It contains a minimum number of wires, which means it is the cheapest option. However, when choosing this circuit, it will not be possible to achieve optimal measurement accuracy - the resistance of the wires used will be added to the resistance of the thermometer, which will introduce an error depending on the length of the wires. In industry, such a scheme is rarely used. It is used only for measurements where special accuracy is not important, and the sensor is located in close proximity to the secondary converter. 2-wire shown in the left picture.

- 3-wire circuit. Unlike the previous version, an additional wire is added here, shortly connected to one of the other two measuring ones. Its main goal is the ability to obtain the resistance of the connected wires and subtract this value (compensate) from the measured value from the sensor. The secondary device, in addition to the main measurement, additionally measures the resistance between closed wires, thereby obtaining the value of the resistance of the connection wires from the sensor to the barrier or secondary. Since the wires are closed, this value should be zero, but in fact, due to the large length of the wires, this value can reach several ohms.Further, this error is subtracted from the measured value, obtaining more accurate readings, due to the compensation of the resistance of the wires. Such a connection is used in most cases, since it is a compromise between the required accuracy and an acceptable price. 3-wire depicted in the central figure.

- 4-wire circuit. The goal is the same as when using the three-wire circuit, but the error compensation is on both test leads. In a three-wire circuit, the resistance value of both test leads is assumed to be the same value, but in fact it may differ slightly. By adding another fourth wire in a four-wire circuit (shorted to second test lead), it is possible to obtain separately its resistance value and almost completely compensate for all the resistance from the wires. However, this circuit is more expensive, since a fourth conductor is required, and therefore is implemented either in enterprises with sufficient funding, or in the measurement of parameters where greater accuracy is needed. 4-wire connection scheme you can see on the right picture.

Note! For a Pt1000 sensor, already at zero degrees, the resistance is 1000 ohms. You can see them, for example, on a steam pipe, where the measured temperature is 100-160 ° C, which corresponds to about 1400-1600 ohms. The resistance of the wires, depending on the length, is approximately 3-4 ohms, i.e. they practically do not affect the error and there is not much point in using a three or four wire connection scheme.

Advantages and disadvantages of resistance thermometers

Like any instrument, the use of resistance thermometers has a number of advantages and disadvantages. Let's consider them.

Advantages:

- almost linear characteristic;

- measurements are quite accurate (error not more than 1°С);

- some models are cheap and easy to use;

- interchangeability of devices;

- work stability.

Flaws:

- small measurement range;

- rather low limiting temperature of measurements;

- the need to use special connection schemes for increased accuracy, which increases the cost of implementation.

A resistance thermometer is a common device in almost all industries. This device is convenient to measure low temperatures without fear for the accuracy of the data obtained. The thermometer is not very durable, however, the reasonable price and the ease of replacing the sensor cover this small drawback.

Similar articles: