A differential proportional-integral controller is a device that is installed in automated systems to maintain a given parameter that is capable of changing.

At first glance, everything is confusing, but PID control can also be explained for dummies, i.e. people who are not quite familiar with electronic systems and devices.

Content

What is a PID controller?

PID controller is a device built into the control loop with mandatory feedback. It is designed to maintain set levels of setpoints, such as air temperature.

The device supplies a control or output signal to the control device, based on the data received from the sensors or sensors. Controllers have high rates of accuracy of transient processes and the quality of the task.

Three coefficients of the PID controller and the principle of operation

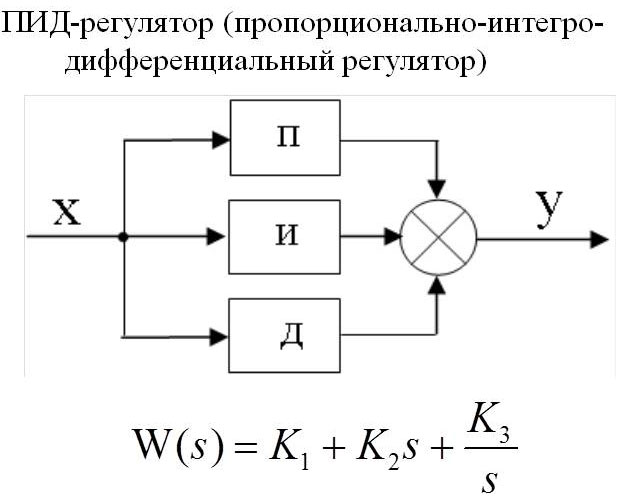

The job of the PID controller is to provide an output signal of the amount of power required to maintain the controlled variable at a given level. To calculate the indicator, a complex mathematical formula is used, which includes 3 coefficients - proportional, integral, differential.

Let us take as an object of regulation a container with water, in which it is necessary to maintain the temperature at a given level by adjusting the degree of opening of the valve with steam.

The proportional component appears at the moment of disagreement with the input data. In simple words, it sounds like this - the difference between the actual temperature and the desired temperature is taken, multiplied by an adjustable coefficient and an output signal is obtained, which should be applied to the valve. Those. as soon as the degrees fall, the heating process starts, they rise above the desired mark - it turns off or even cools down.

Then comes the integral component, which is designed to compensate for the impact of the environment or other disturbing influences on maintaining our temperature at a given level. Since there are always additional factors that affect the devices being controlled, the figure is already changing by the time data is received to calculate the proportional component. And the greater the external influence, the stronger the fluctuations of the indicator occur. Power surges occur.

The integral component tries, based on past temperature values, to return its value if it has changed. The process is described in more detail in the video below.

And then the output signal of the regulator, according to the coefficient, is applied to increase or decrease the temperature. Over time, the value that compensates for external factors is selected, and the jumps disappear.

The integral is used to eliminate errors by calculating the static error. The main thing in this process is to choose the correct coefficient, otherwise the error (mismatch) will also affect the integral component.

The third component of the PID is the differentiator. It is designed to compensate for the influence of delays that occur between the impact on the system and the feedback. The proportional controller supplies power until the temperature reaches the desired level, but when information passes to the device, especially at large values, errors always occur. This may lead to overheating. The differential predicts deviations caused by delays or environmental influences and reduces the supplied power in advance.

PID controller tuning

PID controller tuning is carried out by 2 methods:

- Synthesis implies the calculation of parameters based on the model of the system. This setting is accurate, but requires deep knowledge of the theory of automatic control. It is subject only to engineers and scientists. Since it is necessary to remove the consumption characteristics and make a bunch of calculations.

- The manual method is based on trial and error. To do this, the data of an already finished system are taken as a basis, some adjustments are made to one or more coefficients of the regulator. After turning on and observing the final result, the parameters are changed in the right direction. And so on until the desired level of performance is reached.

The theoretical method of analysis and tuning is rarely used in practice, which is due to ignorance of the characteristics of the control object and a bunch of possible disturbing influences. Experimental methods based on monitoring the system are more common.

Modern automated processes are implemented as specialized modules under the control of programs for adjusting the coefficients of the regulator.

Purpose of the PID controller

The PID controller is designed to maintain a certain value at the required level - temperature, pressure, level in a tank, flow in a pipeline, concentration of something, etc., by changing the control action on actuators, such as automatic control valves, using a proportional , integrating, differentiating quantities for its setting.

The purpose of use is to obtain an accurate control signal that is able to control large industries and even power plant reactors.

Temperature control example

Often PID controllers are used to control the temperature, let's take a simple example of heating water in a tank and consider this automatic process.

A liquid is poured into the container, which must be heated to the desired temperature and maintained at a given level. A temperature sensor is installed inside the tank - thermocouple or resistance thermometer and is directly connected to the PID controller.

To heat the liquid, we will supply steam, as shown in the figure below, with an automatic control valve. The valve itself receives a signal from the regulator.The operator enters the temperature setpoint value in the PID controller, which must be maintained in the tank.

If the controller coefficients are not set correctly, water temperature jumps will occur, with the valve being either fully open or fully closed. In this case, it is necessary to calculate the PID controller coefficients and re-enter them. If everything is done correctly, after a short period of time the system will even out the process and the temperature in the tank will be maintained at a given level, while the degree of opening of the control valve will be in the middle position.

Similar articles: