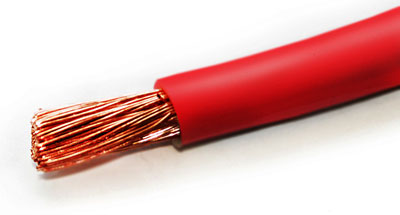

In the process of laying the electrical network, the PV 3 wire can be laid on uneven areas due to its flexibility and versatility. In the material we will talk about the technical parameters, scope and specifics of the PV 3 wire.

PV 3 is a power copper conductor with PVC insulation. With the help of a wire, electrical appliances are connected, power and lighting networks are laid. A characteristic feature of PV3 and its advantage is its flexibility, which allows it to endure bends and turns, laying in hard-to-reach places.

Content

PV wire 3 specifications

A wire called PV 3 stands for: P - wire, V - insulation made of vinyl material, number 3 - category of bending of the electrically conductive core. An increase in the number in the name means an increase in the degree of flexibility.

Key technical characteristics of wire PV 3:

- has one vein;

- laying in power circuits for supplying electric current and lighting networks;

- possibility of application for supplying AC voltage 400V and DC 1000V;

- temperature range from -50 to +75 degrees, laying of copper wire PV 3 is allowed at temperatures from -15 degrees;

- cable PV 3 is normally operated at a humidity of 100%;

- allowable bending angle perpendicular to its axis;

- the declared period of operation of the installation wire PV 3 is approximately 2 years, in fact it is used up to 15 years.

The ground wire is double insulated, so it does not heat up from the current and is widely used for industrial purposes.

Application area

Due to the wide range of cross-sections of the wires, it is widely used in the installation of individual electrical networks, laying electrical cables in an apartment or house, connecting electrical appliances to the network.

Technical parameters make it possible to use PV 3 in the following areas:

- communication complexes;

- residential buildings and industrial premises;

- electrical wiring inside or outside buildings.

Thanks to the reinforced double layer of PVC insulation, complete safety of use is ensured, since such material does not heat up from exposure to high temperatures. Also, the wiring material is not prone to fire.

What are the positive aspects of the wire PV 3

A key feature of the PV 3 grounding cable is the use of vinyl insulating material, which prevents heat and fire. Such material is not destroyed by rodents, since it has a characteristic odor and is hard.The power wire is fixed with brackets, it must not be pierced with nails so as not to damage the insulation.

Advantages of PV 3:

- can be laid in hazardous areas of production, since it is not affected by aggressive external factors, fungus, corrosion;

- the temperature of the wire does not rise in the case of the maximum allowable voltage value;

- corrugated insulation allows laying for high voltage networks;

- the cable is suitable for water heating.

Mechanical characteristics and safety allow it to be used in wooden buildings and buildings made of other materials with an increased level of fire hazard.

PV cable 3 rules of use

Wire PV 3 is used in almost all areas. Laying is also possible at low temperatures from -15 degrees, however, the cable must first be warmed up. If these laying rules are not followed, the cable loses its functionality, and its safety level also decreases. The cable is laid in such places:

- cable channels;

- boxes and trays;

- sleeves and sleeves;

- laying for grounding.

Also, PV 3 is allowed to be laid in the voids of buildings, while cable bends should not exceed 5 outer diameters of the wire. When laying, it is necessary to protect the wire from the ingress of liquid and condensate. The temperature during the passage of electric current should not exceed 70 degrees.

How to choose the right wire PV 3 GOST

When purchasing a wire, it must be tested, during such a test, its electrical and physical characteristics can be identified, as well as potential applications. During the selection process, you need to test the following parameters:

- configuration and dimensions;

- current resistance;

- voltage test;

- detection of the resistance of the layer of insulating material;

- verification of labeling and reliability of packaging.

It is also required to carry out regular testing of the wire, as a result of which it is possible to draw conclusions about the technical parameters during operation:

- conductor resistance for conducting electric current;

- resistance to bending and impact at low temperatures;

- strength and tear resistance;

- thermal shock;

- thermal stability to increase and decrease of degrees of environment.

Tests are carried out in accordance with GOST 6323 and regulations for this type of wire. Testing of compliance with the description and technical parameters during operation is carried out by special organizations in accordance with the technical requirements.

The purchaser, in the selection process, must take into account the dimensions of the wire, which can be calculated using a caliper. It is also recommended to measure the resistance of the cable core: for this, a piece of wire is cut off and measured. To check the insulation layer, you can measure the thickness of the layer and check the ease of removal. In the selection process, you need to pay attention to the coincidence of the wire marking with the marking of the bay, on which the manufacturer's marking should be present. On the cable, the marking is applied every 45-50 cm.

So, PV 3 is the optimal solution for almost any electrical task in everyday life or industrial use. Due to the combination of cost and quality, it will be an ideal solution for most premises.

Similar articles: