To connect household appliances, as well as to equip electrical networks in residential premises, a PVA wire is used. These features have made it one of the most sought-after products in the cable technology market. Many people confuse this conductor with a PVC cable, similar in structure, but with a parallel arrangement of cores. It is necessary to consider the main issues that will help to understand the technical features and classification of the cable, as well as to find out the decoding of the marking applied to the general insulation.

Description and decoding

The PVA cable is a flexible wire that is used to connect devices that consume low power. PVS wires consist of copper conductors. The maximum allowable voltage is 660 V. This conductor is used to connect sockets and lay lighting systems indoors.

The PVA wire, the purpose of which is quite extensive, has the following letter symbols:

- "P" - indicates belonging to the wires that are used to distribute electricity;

- "B" - polyvinyl chloride is used as insulation;

- "C" - designed to connect electrical networks and appliances.

The flexibility of the cable greatly facilitates the laying process. The bending radius must be at least 4 cm. The service life of the cable can reach 10 years. Subject to compliance with all installation standards, PVS wires used as electrical wiring can work for 5 thousand hours.

Design

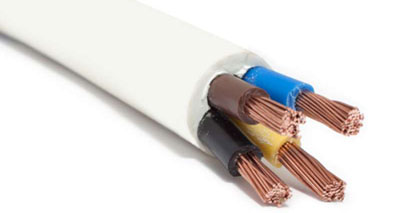

The PVS cable consists of multi-wire cores. It can be tin plated. In this case, the product is marked with the letter "l". The symbol "t" is used to designate an armored conductor.

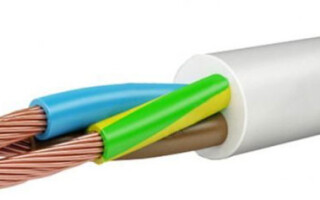

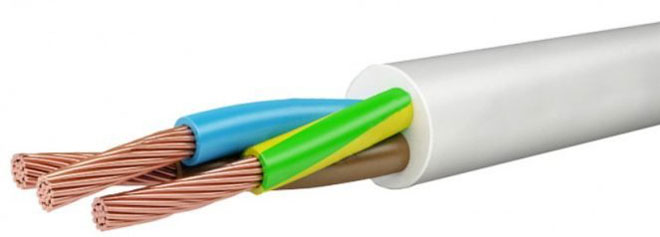

Each copper core is insulated with a PVC coating. In total, no more than five cores can be included in the wire structure. In some types of five-core cable, twisting around the dielectric core is allowed.

For external insulation of the conductor, polyvinyl chloride compound is used, which is applied to fill the voids between the cores. Thanks to this, the PVA wires get a round shape. The outer sheath is easy to cut, so it can be removed without the risk of damaging the strands.

Marking

The color design of the core sheath and external insulation is made in accordance with accepted standards:

- the overall shell is always white, it is allowed to apply two stripes of a different color, which are parallel to each other;

- the zero contour is indicated in blue;

- conductive wires are gray, brown, yellow, black or red;

- yellow-green or green is used to indicate the ground loop.

PVS cable (decoding of additional letters):

- "l" - tinned copper wires;

- capital "T" - tropical version of the cable;

- "B" - armored shell;

- "PS" - the use of a self-extinguishing mixture in insulation;

- "G" - wire without insulation (bare);

- "SHV" - the outer shell has a flat shape;

- "PV" - the use of vulcanized rubber;

- the first digit after the letters indicates the number of cores;

- the second digit is the cross-sectional area.

Characteristics

GOST 7399-97 regulates the technical properties of different brands of cable, but it should be remembered that it only defines a range of values. That is, each manufacturer can set the actual parameters independently. To find out exact information, for example, the diameter or size of the purchased conductor, it is necessary to study the accompanying documentation.

PVA cable specifications:

- The operating range of ambient temperature is -25…+40°C. If the symbol “Y” is present in the marking, the negative temperature can reach -40°C. The maximum heating of the cores during operation is not higher than + 70 ° С;

- When laid alone, it does not spread combustion.

- The maximum air humidity is 98%.

- As an electrical wiring in a room, the working life is 5 thousand hours, when used in electrical equipment - 12 thousand hours.

- The minimum bending radius is 4 cm (if the cross section is not more than 1 mm²), with a larger diameter - 6 cm.

- Resistance to alternating deformation - 30 thousand cycles.

- PVA wire with technical characteristics that allow operation in tropical conditions (marking "T"), resistant to mold and fungi.

- Line voltage 380-660 V.

- The warranty period is counted from the moment the conductor is put into operation, it is 2 years.

The standard modification of the cable is capable of withstanding an alternating voltage of 2 kW for 5 minutes. If it is immersed in water for 1 hour, then the test time should increase to 15 minutes. The tensile strength of the wire reaches 10 N / mm², while its length can increase by 1.5 times.

The cable is sold in coils or drums. The standard length of the segment varies between 30-200 m.

Scope and features of PVA

The scope of the PVA wire depends on the number of cores and the material used in them. A conductor with copper conductors is more in demand. It is suitable for arranging the electrical network of both industrial and residential premises. With the help of a conductor with a thick section, it is possible to electrify a settlement, connect a power plant or replace wires in a transformer.

PVA wire with copper conductors has the following advantages:

- high level of elasticity and strength;

- do not give in to corrosion;

- reliable work with rheostats and insulators;

- copper has the best thermal expansion parameters.

The cable is able to withstand high mechanical and electrical loads. However, to ensure high-quality and safe use, it is necessary to take into account all available factors.

Similar articles: