Sometimes the house needs replace old wiring or increase the number of outlets, lighting fixtures, and so on. To prevent the wires from passing along the surface of the wall, spoiling the appearance, a gating procedure is carried out. Work on cutting the strobe is carried out during major and cosmetic repairs, when laying electrical wiring in a new building.

Content

Requirements, norms and restrictions when chasing walls for wiring

Shtroblenie is a construction work that is carried out in order to carry out the installation of wiring, as well as other communications. Shtroba - a special recess in the surface, made with a special tool.

This is labor intensive and difficult work. Usually, professional workers with experience are involved in its implementation. Otherwise, improperly performed gating can deform the supporting structures, damage communications, create an emergency, even before the building collapses.

IMPORTANT: gating work must be coordinated with the architecture department.

When cutting the strobe, it is not recommended:

- Use a ladder because it is unstable. Working with a heavy tool can result in injury.

- Use tools that are defective or damaged. During work, they experience a lot of stress, and the presence of defects in the tool can lead to its complete breakdown and injury to the worker.

Wall chasing tool

For this type of work, different tools are used. Which one to use depends on the material in which the strobes will be cut.

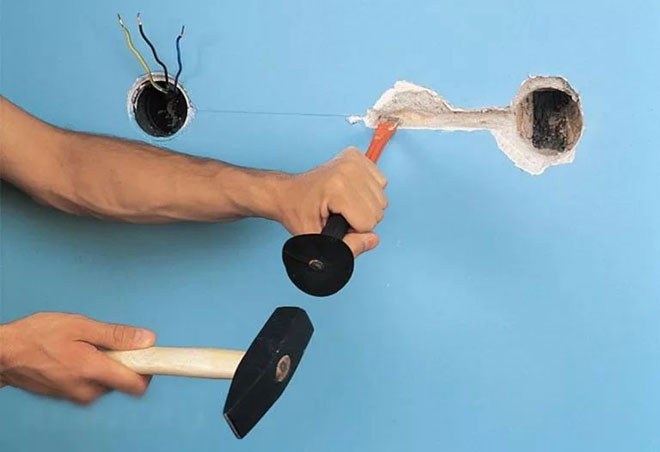

Hammer and chisel

This tool is suitable for work on material with low hardness - plaster, foam concrete, soft stone, sometimes brick, if the chisel has a hard tip.

Pros:

- No need to spend money on expensive tools;

- A small amount of dust during work.

The downside is that it takes a lot of time and effort. This method is best used where a small scale of work.

Perforator with nozzle

It is used for chasing in masonry and concrete walls.Not suitable for high strength concrete base.

Pros:

- Affordable price for the tool;

- Small amount of dust;

- To work with the tool does not require special skills.

Minuses:

- Rough edges of the strobe, requiring additional alignment work;

- Noise.

Drill attachment

An electric drill with a hammer function is also used for work. It requires a drill or nozzle with a shortened drill and a blade that acts as a chisel.

Holes are made with a drill or drill according to the marking. Their depth is not more than 25 mm, the distance between the holes is 10-15 mm. The drill is replaced with a spatula, which equips the gutter for wiring.

Universal grinder

Suitable for cutting in any material hardness.

Pros:

- The work does not take much time;

- The edges of the strobe are smooth;

- The tool is inexpensive and easy to use.

Minus in the formation of a large amount of fine dust during operation.

wall chaser

Designed for cutting strobes in bases made of materials of various hardness. This is a highly specialized and expensive tool. Mostly professionals work with him. In the wall chaser, the adjustment of the produced gate in width and depth is provided. The track for wiring does not require additional processing. The tool comes with a dust collector.

ATTENTION: When working with power tools, you must follow safety precautions and protect yourself and other workers from electric shock.

When chipping, you will also need:

- Tester or hidden wiring detectorto find the location of the old electrical wiring;

- level;

- vacuum cleaner;

- Personal protective equipment.

Wall chipping technology

Electrical wiring is laid in concrete at the first stage of repair activities. Chasing in a populated area is not recommended, as the work is very dusty. First you need to remove furniture, office equipment, etc. If this is not possible, then cover them with a film or other material to protect them from dust. You will also need a construction vacuum cleaner, with which you will need to remove debris and dust.

Preparing the room and marking the work surface

Before starting work, it is necessary to check the location plan of the old wiring. If there is no such plan, then with the help of a tester or indicator you need to detect it and note how it goes. It is best to de-energize the old wiring, but if this is not possible, then try to lay a new one without intersecting with it. This is to prevent electrical injury.

The new wiring route is marked on the walls. Marking is carried out from junction boxes to all connection points.

Basic rules for chasing

During work, protection of hands, eyes and respiratory organs must be provided. To do this, use a respirator, durable gloves and goggles. It is recommended to carry out chasing with a rubber mat underfoot.

It is important to observe the following rules:

- Gates are made parallel to the main structures of the building in a vertical or horizontal form. An exception is the attic, where chasing can be carried out on a base with a slope.

- Horizontal strobes are made at least 150 mm away from the ceilings. Vertical furrows are made with an indent of at least 100 mm from door and window openings, as well as corners.

- The distance between the strobe furrow and the gas pipes must be at least 400 mm.

- In load-bearing walls, horizontal strobes are not recommended.

- It is forbidden to use an inter-plate joint instead of a strobe furrow.

- With a structure thickness exceeding 8 cm, the electrical wiring is laid in a short way, if less - parallel to the construction lines.

Distances, depth, strobe width

Grooves for electrical wiring are limited in size. The width of the strobe should not exceed 30 mm, the depth - 26 mm. The length of the groove from the distribution point to the connection point must not exceed 3 m.

To what depth is it forbidden to ditch in load-bearing walls

Sometimes chasing needs to be done along a load-bearing wall. In this case, the depth of the strobe should not exceed 20-30 mm. If you make the groove deeper, then there is a risk of damaging the fittings located in the wall. This is not only a violation of the rules, but can also lead to collapse.

Sockets

The location of sockets and junction boxes is marked on the wall according to the electrical diagram.

Steps for grooving under sockets:

- A hole with a diameter of 8 mm is drilled in the center of the connection point;

- The contour of the niche for the outlet is outlined using a special nozzle (crowns) on a drill;

- Holes are drilled along the line of the entire outlined contour;

- Using a drill with a nozzle-crown, a niche is drilled under the connection point.

Seal the strobe in the wall

After the electrical wiring is laid in the grooves made, it is necessary to plaster the strobes.

Actions when sealing gate channels:

- Clean the furrow from dust using a construction vacuum cleaner or an ordinary broom.

- Prime the strobe by applying the primer liberally with a brush. Allow the liquid to dry completely.

- Wet the strobe with water and start embedding. Work can be carried out with special plaster, building gypsum or using mounting foam.

Gating features

Cutting a strobe has its own nuances and non-standard situations, in the event of which there are standards and rules that differ from the general ones.

Chasing walls for air conditioning

To install a household air conditioner that has two standard units, you will need a strobe with special dimensions. The width of such a groove is at least 60 mm, the depth is 50 mm.

This is necessary so that all the wiring and other elements necessary to connect the air conditioner fit freely in the strobe and are not damaged.

Shredding wooden walls

Fire safety regulations prohibit chasing walls in wooden buildings, this also applies to baths. In the event of a short circuit, there is a risk of ignition of the walls from the electrical wiring laid in them. In this case, special cable channels are used.

Strobe in tiled floor

Sometimes you have to lay wiring on already glued tiles. Such work is performed only by a grinder or a wall chaser with diamond discs installed on them. A puncher or drill is not suitable for this purpose, as their use can lead to chips and cracks in the tile.

Monolithic walls

Chasing in a monolithic base can be dangerous for the entire structure of the building. This is due to the fact that all the walls of such a building are load-bearing and create a single structure. Their frame of reinforcement is connected to each other.Any violation of it can lead to catastrophic consequences.

Such work is carried out only in case of emergency, with the appropriate permits and with the involvement of specialized organizations.

The organization must have a license for chasing in monolithic walls, a professional and serviceable tool, and qualified workers.

Chasing the ceiling in a panel house

Is it possible to ditch the ceiling and floor in a panel house at all? To answer this question, you need to refer to GOST and the clause prohibiting the violation of the integrity of the structure of the building, due to which a collapse may occur.

Carrying out such work in a panel house fits this item and carries the risk of collapse. Hence the conclusion: chasing the ceiling and floor in a panel structure forbidden.

But experts still admit that a single furrow with a depth of not more than 10 mm for connecting a lighting point is possible if there are no other ways to place the wiring.

How to get rid of dust?

The tool that comes with the dust collector can protect against a large amount of dust. It makes no sense to spend money on such equipment for one session of gating. Some tips from professionals will help you avoid heavy dusting:

- During the manufacture of the strobe, use water to wet the cutting area. Water can be supplied through a hose or with the help of a partner who will pour it from any container.

- Use a household vacuum cleaner to collect small particles.

- In the place of work, cover the surface with a film.

- Hang a wet cloth on the door, and put a damp rug in front of it. This will help to minimize the ingress of dust and dirt into adjacent rooms.

ATTENTION: when watering the place of gating, it is important to ensure that water does not get on the live parts of the tool.

Taking into account the advice and recommendations of specialists, following the norms and without violating the rules, surface chasing can be done independently. Excluding those cases where you still cannot do without the help of professionals.

Similar articles: