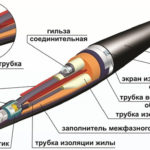

After the wiring is completed, the issues of ensuring the safety and protection of the connection during the further operation of the wiring become a priority. In the process of laying electrical networks, special attention must be paid to compliance with the technology and quality standards when laying and connecting cables, because these sections of electrical wiring are the most vulnerable. To prevent burnout and emergency situations, insulation and heat shrink tubing of different categories are used.

A heat shrink tube is an elastic product made of a thermopolymer material that is subject to heat shrinkage. That is, the temperature regime affects the length and diameter, hot water, air or fire can act as a source of temperature.

A distinctive feature of the tubes is the increased transverse compression value compared to the longitudinal compression. This means that the diameter of the heat-shrinkable tube can be reduced by several times (from 2 to 6), and the maximum increase in length is 20%.

Content

General information and scope of heat shrink tubing

The production of heat shrink tubing at the factory is carried out from a special heat shrinkable material, which changes dimensions several times depending on the degree of temperature increase. The product is influenced by the surrounding elements - water, flame, air. If one end is heated, the dimensions of the heat shrink tube will increase only in this area, while the other end will remain in the same size range. With a decrease in diameter, a proportional increase in the thickness of the thermopolymer walls occurs, as a result of which the insulating characteristics of the heat shrink tubing for electrical wiring insulation also increase.

The heat shrink tube HERE is able to shrink in size under the influence of temperature and fit the wire. HERE applies to the following areas:

- performance of electrical work in order to ensure reliable electrical insulation. Heat shrink has a lot of advantages over conventional electrical tape, especially when there are a large number of connections;

- marking of cables and electrical wiring - in this case, heat shrink tubes are used as cambric;

- providing anti-corrosion protection of joints in many areas;

- a means to ensure the mechanical stability of operating mechanisms. So, often heat shrink tubes are used on conveyor rollers and rollers;

- in the production of thermotubes provide reliable protection of connections from the aggressive effects of external factors, including precipitation.

Advantages and disadvantages

Heat shrink tubing has the following features:

- due to the tight fit, it does not move under mechanical action;

- using and installing heat shrink tubing is a simple task that you can easily do yourself;

- a large selection of materials and diameters of heat shrink tubing;

- after shrinkage, the heat shrink tube HERE acquires additional strength and rigidity at the junction;

- when choosing which is better - heat shrinkage or electrical tape, heat shrinkage definitely has advantages in terms of technical characteristics and a longer service life.

The disadvantages include the following factors:

- the impossibility of reuse, since the diameter has changed under the influence of temperature, and it is impossible to remove HERE without damage;

- the cost is higher than that of electrical tape.

Types of heat shrink

Types of TUT thermopolymer heat shrink tubing are distinguished based on the production method and the material used:

- polyolefin. They are made from polyethylene glued by chemical or radiation means, to which dyes, plasticizing components, and fire-fighting agents are added. Most tubes are manufactured using this method, they are designed for a temperature range from -50 to 125 degrees. Also, the material is resistant to benzene and oxidizing agents with short-term contact;

- elastomers based on synthetic rubber.A characteristic difference is resistance to temperatures up to 175 degrees and the presence of oil and petrol resistant properties, however, the price is often too high, which hinders the growth of popularity;

- heat shrink for wires made of thermoplastic polyvinyl chloride. The material provides a high level of insulation, but a small range of operating temperatures from -20 to 80 degrees;

- polyester has a high level of chemical resistance and resistance to mechanical damage. The material is ideal for the manufacture of thin-walled products;

- fluoropolymer - require complex technological processing, provide unique chemical and physical characteristics;

- silicone products - are characterized by plasticity and non-toxicity, but are not resistant to organic solvents.

Also classified HERE by installation method:

- adhesive heat-shrinkable tube, in which a layer of glue is applied on the inside, providing a high degree of tightness and tight fit. Also, with the help of this type, protection against moisture ingress is provided;

- HERE without an adhesive layer for standard connections where there is no need to ensure tightness.

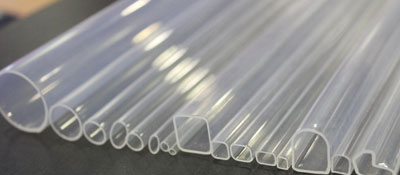

By color, decorative HERE are distinguished for an additional decorative effect, and a transparent standard heat shrink is recommended for use in places where it is necessary to check the tightness of the connection.

Depending on the wall thickness, there are: thin, medium and thick walls.

For specific tasks, special types of TUT are produced with additional functions, for example, heat shrinkage with solder, with a corrugated surface, high electrical density, specific cold shrinkage material, and others.

Characteristics and differences

The main parameters that characterize a heat-shrinkable tube are:

- heat resistance;

- shrinkage ratio in the range from 200 to 600%;

- the diameter of the heat shrink tube before and after exposure to temperature;

- oil resistance;

- chemical inertness;

- the ability to withstand voltage up to 1000V;

- petrol resistance;

- resistance to ultraviolet radiation;

- anti-flammable properties;

- shrink temperature and operating range.

Products can be produced in round, oval and compressed form, which does not affect the installation. Note that thin wall heat shrink tubing is mainly produced in oval or flattened shape.

diameter before and after

Heat shrink for wires changes its dimensions with increasing temperature. For this reason, the name of the manufacturer indicates the size before and after heating. For example, if the name says HERE NG 40/20, then 40 mm is the inner diameter before shrinkage, 20 mm after. When connecting cables of different cross-sections and diameters, heat shrinks with large coefficients are required.

The amount of shrinkage must also be taken into account when choosing the length of the products. For high-quality tubes, shrinkage along the length is no more than 5-7%, while for Chinese ones it is about 20%.

When choosing a large diameter heat shrink tubing, you need to pay attention to both shrinkage parameters. The higher the degree of shrinkage, the thicker the tube walls become after heating, which as a result significantly increases the density and strength of the joint. Thick-walled products have optimal shrinkage rates.

Shrinkage ratio

The compression ratio assumes that the products are characterized by longitudinal shrinkage. This parameter varies from 2:1 to 6:1, that is, it has the ability to shrink 2-6 times from its original shape. The coefficient means the ratio of the initial diameter to the diameter after shrinkage.

HERE with a large coefficient are more expensive, since the process of their manufacture is more complicated. Tubes 4 to 1 are considered more versatile than 2 to 1.

Wall thickness

The thickness of the walls is of no small importance, HERE are available in the following versions:

- thin-walled;

- with medium walls;

- thick-walled.

It is necessary to choose the wall thickness based on the scope and functions assigned to the heat shrink tube.

Flame Retardant Heat Shrink Tubing

Significant importance is attached to the material of production, because it is he who has the characteristics required from the product. For example, options with fire retardants are characterized by self-extinguishing, and their names indicate the value of NG.

However, it is impossible to say that it does not burn at all. In the absence of an open flame, the product will extinguish itself. This happens due to the effect of fire retardants, which displace oxygen in the fire.

Note that when VVG NG wiring is used indoors, then the insulation should be done with similar heat shrink tubes. The heat-resistant and non-flammable heat-resistant tube will reliably prevent the occurrence of fires, thereby minimizing the risk of accidents.

Color matching

Colored decorative heat shrink tubing is convenient for labeling as a small ring of eye-catching color is placed on the insulation at the end of the cable.Here are the basic rules for using colored tubes:

- in the wiring of DC electrical circuits, red is used on the plus and black on the minus;

- on the ground wires - yellow-green tint;

- in a three-phase electrical circuit - red, yellow and green colors in phases.

Due to the wide range of colors, heat-shrinkable tubes can be used as a decorative material.

Installation rules

Before answering the question of how to use heat shrink, we note that for this process it is recommended to have specialized equipment - a heat installation. It sets the required shrinkage temperature to facilitate the procedure. Alternatively, you can use a lighter or place the tube in boiling water.

Here is the sequence of actions and rules for using HERE:

- before installation, it is recommended to heat a thick-walled or large-diameter tube with a hot air gun to half the temperature specified in the parameters for shrinkage. Thin-walled tubes do not need to be preheated;

- cut off the required segment HERE with scissors, while making sure that there are no burrs and uneven edges in order to avoid tears during operation;

- stretch the tube and pull it into place;

- heat up to the temperature specified in the specification, but do not exceed the limit to avoid deformation. Hot air must be directed from one end to the other or heated from the center to the edges;

- allow the tube to cool, after which the process is completed.

So, installing heat shrink tubing is a simple task, the main thing is not to exceed the temperature and heat evenly. If deformation or mechanical damage is detected, the tube must be replaced with a new one.

Similar articles: