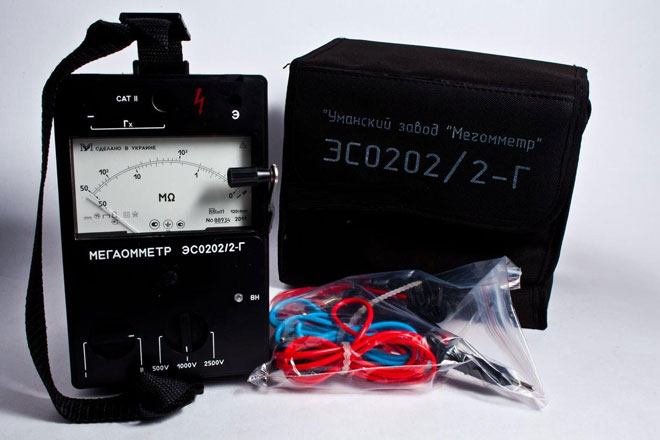

To measure the resistance value, as well as to identify defects in cables and wiring of electrical networks, a megohmmeter specially designed for this purpose is used.

Three words are clearly recognizable in the name of the device:

“Mega”, “Ohm”, and “Meter”, where the first word implies the value of the measured quantity, the second - the unit of measurement and the third derivative of the word “measure”.

The working process of the megohmmeter is based on the principles of Ohm's law regarding sections of the electrical circuit, so any modification of the device contains in the inside of the case:

- current measuring system (ammeter);

- a set of output terminals;

- constant voltage generator.

The design features of voltage generators can vary within fairly wide limits. Their production is based on the simple manual dynamos that were used before. Modern generators are equipped with built-in or external power sources.

The output power and voltage of the generator can vary within several intervals, and also have a single, fixed value.

On the one hand, the connecting wires are connected to the terminals of the megohmmeter, and on the other hand, they are fixed in the measured circuit with the help of “crocodiles”. These are special devices designed for a more reliable connection.

With the help of an ammeter, which is built into the unit, the indicators of the current passing through the circuit are measured.

Note! with a known and calibrated generator voltage, units of resistance are also calibrated, that is, on the scale located on the measuring head, megaohms, kiloohms, or both are shown together.

On the scale of one of the most reliable proven analog megohmmeters, released about fifty years ago M4100 / 5, there are two scales, which allows you to measure at two boundaries. New technologies display resistance readings more clearly. The already processed digital signal is displayed on the digital display.

Content

Arrow megohmmeter and its device

A simplified electrical circuit typical for analog devices is equipped with the following components:

- DC generator;

- measuring head, which consists of two interacting frames (working and counteracting);

- a toggle switch between measurement limits, which allows you to adjust the operation of various resistor chains designed to correct the output voltage and operating modes of the head;

- current limiting resistor.

In turn, the dielectric sealed durable housing of this unit is equipped with:

- handle for comfort in transportation;

- a folding portable handle of the generator, rotating which generates voltage;

- a lever with which the measurement modes are switched;

- output terminals designed for the operability of the entire circuit (connecting wires are connected to the terminals).

Most megger models have three output terminals for connection. Each of them has a name: earth (Z), line (L) and screen (E).

Z and L are designed for measuring insulation resistance. E - in order to eliminate the influence of current losses in the case of a measurement in the area of two parallel cable cores.

The device is supplied with a special test lead with a characteristic design and a shielded end equipped with two terminals. On one of them there is a marking in the form of the letter "E". What does it mean? This means: that it should be connected to the appropriate terminal located on the megohmmeter.

For megohmmeters based on the operation of an external network, the same principle of operation is characteristic, the handle is no longer spinning here, that is, in order to give out voltage for the circuit under test, you just need to hold down the button specially designed for this. A device capable of delivering more than one combination of voltage is equipped with several buttons, respectively. There can be two, three ... even several sets of combinations. Such megohmmeters have a more complex internal structure.

Note! Devices have increased voltage, so when using them, safety precautions must be observed.

Negligence in work with a high level of danger is unacceptable. So how to use a megaohmmeter correctly? From all the above, the conclusion suggests itself:

According to safety measures when working with a megohmmeter, only a specially trained and trained person can take measurements. His specialization should allow carrying out repair work on electrical installations that are energized.

When measuring the circuit under test, the connecting wires and terminals have an increased voltage, so working with them requires the use of special probes. They are installed in the area of measuring wires, the surface of which is heavily insulated.

The effect of the residual charge

A working megohmmeter generator produces voltage, so the earth circuit forms different potential values, due to which a semblance of a container with a certain charge is created. After the measurement, some part of the capacitive charge remains in the wire. As soon as a person touches this area, electrical injury is guaranteed, so the constant use of additional security measures will not be superfluous, namely:

- portable grounding;

- insulated handle;

- Before connecting the device to the circuit under test, check the presence of voltage in it, as well as residual charge using a voltmeter.

How to ensure the safety of working with a megohmmeter

The work is carried out exclusively with the help of serviceable megohmmeters (checked and tested in a metrological laboratory specially designed for this purpose). Verification allows the owner of the unit to have a special certificate that gives a time-limited right to carry out work, that is, until a certain expiration date. After verification, a specialist puts a stamp on the body of the device, indicating that the control verification has been carried out. The stamp contains the date and number of the inspector.It is the responsibility of the owner of the megohmmeter to maintain the integrity of the brand, since it is it that gives the right to carry out subsequent measurements. No stamp means: the device is not working!

When performing several measurements in a row in a ten-core cable, you should always use portable grounding, and also remove the residual charge after each measurement. Fast and safe work with the megger is ensured by connecting one end of the ground conductor to the ground loop until all work is completed. The second end of the conductor is attached to an insulating rod, which is designed for the convenience of reusable grounding in order to safely remove the residual charge.

How to connect a megaohmmeter?

For each model of devices for this purpose, the value of the output voltage is determined, therefore, in order to effectively test the insulation or measure its resistance, it is necessary to choose the right megohmmeter.

To check the cable insulation with a megohmmeter, a so-called extreme case is created, in which a voltage higher than the nominal voltage is applied to the test section, but within the permissible limits prescribed in the technical documentation.

For example: a megaohmmeter generator can produce:

- 100V;

- 250V;

- 500V;

- 700V;

- 1000V;

- 2500V.

Accordingly, the voltage supply should be an order of magnitude greater.

The duration of the measurement process usually does not exceed 30 seconds or a minute, this is necessary for more accurate detection of defects, as well as to exclude their subsequent occurrence during voltage drops in the network.

The basis of the technological process of measuring resistance is: preparation for the process, its implementation and the final stage. Each of them includes a certain list of manipulations necessary to achieve the goal without harm to others and, first of all, to yourself.

In preparation for work, you should organize your actions, study the electrical installation diagram in order to exclude possible damage, and also ensure your safety.

Before starting work, you should first check the device for serviceability. To do this, the conclusions are connected to the measuring wires. Then their ends are connected to each other trying to short-circuit. After the voltage is applied, the measurement readings are measured (they must be equal to zero). The next step involves a re-measurement. If there are no faults, the reading should be different from the previous one.

Then they connect the portable ground to the ground loop, check and ensure that there is no voltage on the site, install a portable ground, assemble the measuring circuit of the device, remove the portable voltage, remove the residual charge, disconnect the connecting wire, remove the portable voltage.

The final stage involves the restoration of disassembled chains, the removal of shunts and shorts, as well as the preparation of the circuit for the operating mode. The obtained results of measurements of the resistance of the insulating layer in the act of checking the insulation are documented.

Similar articles: