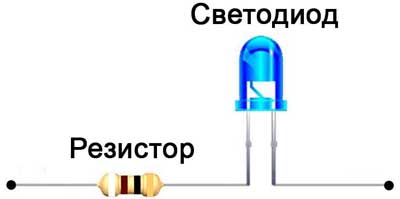

The main parameter affecting the durability of the LED is the electric current, the value of which is strictly standardized for each type of LED element. One common way to limit the maximum current is to use a limiting resistor. The resistor for the LED can be calculated without the use of complex calculations based on Ohm's law, using the technical values \u200b\u200bof the diode parameters and the voltage in the switching circuit.

Content

Features of turning on the LED

Working on the same principle as rectifier diodes, light emitting elements, however, have distinctive features. The most important ones are:

- Extremely negative sensitivity to reverse polarity voltage. An LED connected to the circuit with the wrong polarity fails almost instantly.

- Narrow range of permissible operating current through the p-n junction.

- Dependence of transition resistance on temperature, which is typical for most semiconductor elements.

The last point should be discussed in more detail, since it is the main one for calculating the quenching resistor. The documentation for the radiating elements indicates the permissible range of the rated current, in which they remain operational and provide the specified radiation characteristics. Understating the value is not fatal, but leads to some decrease in brightness. Starting from a certain limit value, the passage of current through the transition stops, and the glow will be absent.

Exceeding the current first leads to an increase in the brightness of the glow, but the service life is sharply reduced. Further increase leads to the failure of the element. Thus, LED resistor selection aims to limit the maximum current allowed under worst-case conditions.

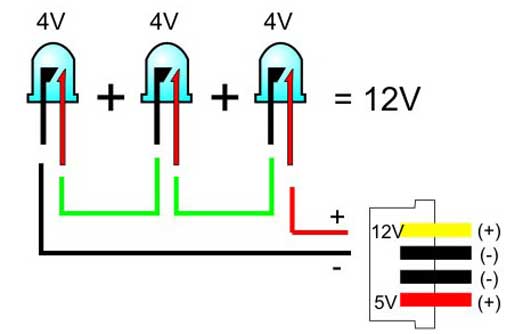

The voltage at a semiconductor junction is limited by the physical processes on it and is in a narrow range of about 1-2 V. 12 Volt light emitting diodes, often installed on cars, may contain a chain of series-connected elements or a limiting circuit included in the design.

Why do you need a resistor for the LED

Using limiting resistors when turning on LEDs is, although not the most effective, but the easiest and cheapest solution to limit the current within acceptable limits. Circuit solutions that allow you to stabilize the current in the emitter circuit with high accuracy are quite difficult to repeat, and ready-made ones have a high cost.

The use of resistors allows you to perform lighting and backlighting on your own. The main thing in this case is the ability to use measuring instruments and minimal soldering skills. A well-designed limiter, taking into account possible tolerances and temperature fluctuations, is able to ensure the normal functioning of the LEDs during the entire declared service life at minimal cost.

Parallel and serial connection of LEDs

In order to combine the parameters of the power circuits and the characteristics of the LEDs, serial and parallel connection of several elements is widespread. Each type of connection has both advantages and disadvantages.

Parallel connection

The advantage of such a connection is the use of only one limiter for the entire circuit. It should be noted that this advantage is the only one, therefore, a parallel connection is practically never found, with the exception of low-grade industrial products. The disadvantages are:

- The power dissipation on the limiting element increases in proportion to the number of LEDs connected in parallel.

- The scatter of the parameters of the elements leads to uneven distribution of currents.

- The burnout of one of the emitters leads to an avalanche-like failure of all the others due to an increase in the voltage drop across the group connected in parallel.

The connection somewhat increases the operational properties, where the current through each radiating element is limited by a separate resistor. More precisely, it is a parallel connection of individual circuits consisting of LEDs with limiting resistors.The main advantage is greater reliability, since the failure of one or more elements does not in any way affect the operation of the others.

The disadvantage is the fact that due to the spread of the LED parameters and the technological tolerance for the resistance value, the brightness of the glow of individual elements can vary greatly. Such a scheme contains a large number of radio elements.

Parallel connection with individual limiters finds use in low voltage circuits, starting with a minimum, limited by the voltage drop at the p-n junction.

Series connection

The series connection of radiating elements has become the most widespread, since the undoubted advantage of a series circuit is the absolute equality of the current passing through each element. Since the current through the single limiting resistor and through the diode is the same, then the power dissipation will be minimal.

A significant drawback is that the failure of at least one of the elements will lead to the inoperability of the entire chain. For a series connection, an increased voltage is required, the minimum value of which increases in proportion to the number of included elements.

mixed inclusion

The use of a large number of emitters is possible when performing a mixed connection, when several chains connected in parallel are used, and a series connection of one limiting resistor and several LEDs.

The burnout of one of the elements will lead to the inoperability of only one circuit in which this element is installed.The rest will function properly.

Resistor calculation formulas

The calculation of resistor resistance for LEDs is based on Ohm's law. The initial parameters for how to calculate the resistor for the LED are:

- circuit voltage;

- operating current of the LED;

- voltage drop across the emitting diode (LED supply voltage).

The resistance value is determined from the expression:

R = U/I

where U is the voltage drop across the resistor and I is the forward current through the LED.

The voltage drop of the LED is determined from the expression:

U \u003d Upit - Usv,

where Upit is the circuit voltage, and Usv is the nameplate voltage drop across the radiating diode.

Calculating an LED for a resistor gives a resistance value that will not be in the standard range of values. You need to take a resistor with a resistance closest to the calculated value on the larger side. This takes into account the possible increase in voltage. It is better to take the value next in the series of resistances. This will somewhat reduce the current through the diode and reduce the brightness of the glow, but at the same time, any change in the magnitude of the supply voltage and diode resistance (for example, when the temperature changes) is leveled.

Before choosing a resistance value, you should evaluate the possible decrease in current and brightness compared to that specified by the formula:

(R — Rst)R•100%

If the value obtained is less than 5%, then you need to take a larger resistance, if from 5 to 10%, then you can limit yourself to a smaller one.

An equally important parameter that affects the reliability of operation is the power dissipation of the current-limiting element. The current passing through a section with resistance causes it to heat up.To determine the power that will be dissipated, use the formula:

P = U•U/R

Use a limiting resistor whose power dissipation will exceed the calculated value.

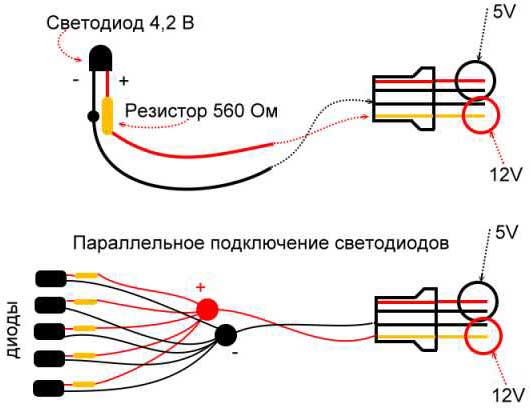

Example:

There is an LED with a voltage drop across it of 1.7 V with a nominal current of 20 mA. It must be connected to a 12 V circuit.

The voltage drop across the limiting resistor is:

U = 12 - 1.7 = 10.3 V

Resistor resistance:

R \u003d 10.3 / 0.02 \u003d 515 ohms.

The nearest higher value in the standard range is 560 ohms. With this value, the decrease in current compared to the set value is slightly less than 10%, so there is no need to take a larger value.

Dissipated power in watts:

P = 10.3•10.3/560 = 0.19 W

Thus, for this circuit, you can use an element with a permissible dissipation power of 0.25 W.

Connecting the LED strip

LED strips are available for different supply voltages. On the tape is a circuit of series-connected diodes. The number of diodes and the resistance of the limiting resistors depend on the supply voltage of the tape.

The most common types of LED strips are designed to be connected to a 12 V circuit. Using a higher voltage value for operation is also possible here. For the correct calculation of resistors, it is necessary to know the current flowing through a single section of the tape.

An increase in the length of the tape causes a proportional increase in current, since the minimum sections are technologically connected in parallel. For example, if the minimum length of a segment is 50 cm, then a 5 m tape out of 10 such segments will have a 10-fold increase in current consumption.

Similar articles: