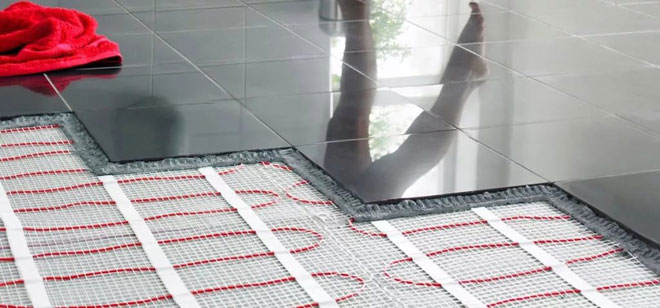

Heating and maintaining heat in a residential area is an urgent issue today. The surface of the floor of the kitchen, bathroom, bathroom or hallway is most often a cool ceramic coating. In summer, this factor can be pleasant, but in winter, cold floors become a problem, especially for families with small children. Electric underfloor heating under tiles is an acceptable method of solving this issue. It is not difficult to install underfloor heating on your own if you know the basic techniques of how to lay heating elements under the tiles.

Content

What are the options

The high heat dissipation of ceramic tiles is its advantage for underfloor heating in any way.

The electrical coating device can be of several types:

- cable;

- film;

- heating mats;

- rod.

With the cable method, the installation of an electric underfloor heating under the tiles consists in laying a heating resistive cable, which is attached with special clips on the slats. A cheaper cable is single-core, but two-core is more often used, which has high reliability. Sometimes a cable is used, between the two conductors of which lies a polymer matrix that produces heat.

You can purchase ready-made kits for this heating method, the price of which depends on the components, length and power of the cable. A full set of kit can even contain tools. It is more economical to independently select heating elements and install a warm floor with your own hands.

The infrared film method is an expensive, but the safest method, which uses a flexible polymer web with built-in infrared heating elements.

Heating mats consist of a mounting mesh with a cable attached to it. Their laying does not require the use of concrete pouring, which increases the load on the floors and reduces the height of the ceiling. The method is easy to install, so it is very popular. The final choice of underfloor heating for tiles is associated with the calculation of optimal heat transfer. In this case, the calculation of the heating capacities of the mats is much simpler than the lengths of the heating cables.

In the variant of the rod method, carbon rods connected in series are used. The installation kit includes rod mats, wires and connecting kits, other elements (thermostat, thermal insulation, bituminous insulation, adhesive tape, etc.) are purchased separately.

Surface preparation

The technology of laying a warm floor provides for careful preparation of the surface before putting the heating elements. Heating mats or cables may only be laid on a clean and leveled floor without projections or cracks. It is possible to use a primer, concrete screed or self-leveling floor.

Surface thermal insulation

To minimize heat losses and achieve efficient space heating, a heat-insulating layer is used during preparation. Depending on the required thickness of the insulation, the following materials are used:

- Styrofoam;

- expanded polystyrene;

- foil foam.

On balconies, loggias, above unheated rooms or basements, thick insulating materials up to 100 mm (such as polystyrene foam and expanded polystyrene) are used. For a thin layer of insulation, foil foam is used (the reflective surface of the foil should be directed upwards). All connections and seams are hermetically fixed with foil tape. The heated floor under the tiles in the bathroom is additionally equipped with a layer of waterproofing.

Schema Design

Before installing the heating system, it is necessary to develop a plan on paper. Buffer zones with massive furniture, household appliances, heating batteries and pipes are separated in it. It is impossible to lay heating systems under furniture or household appliances, as an additional load is created on the cable (due to the impossibility of leaving the heat up, the cable overheats).

It turns out an irregular polygon inscribed in the rectangle of the room.The diagram shows the contour of the future electric floor, the power supply and the location of the thermostat on the wall (at a height of about a meter). You should also retreat from the walls up to 20 cm and calculate that the distance between the turns of the cable is at least 10 cm. From the paper drawing, the markings are transferred to the prepared floor surface. A properly designed circuit will reduce the cost of purchasing a heating system and protect the cable from overheating.

Material calculation

The required power density of the cable is calculated taking into account the area of the floor that will be covered by the heating system. Before purchasing materials, it is necessary to calculate the heating area and cable power. All measurements can be done using computer programs or use the services of a sales assistant in the store. You can independently calculate the cable length by multiplying the heated surface area by the selected specific power and dividing the result by the cable power.

Depending on the characteristics of the room, the power consumption of the electric floor can range from 100 to 180 watts/m². A dry, heated room heated by another source will require up to 120 watts / m². At high humidity, for example, in the bathroom, power up to 150 watts/m² is used. On a balcony, loggia or in an unheated room, the power can reach 180 watts / m². Floor heating under tiles can be the main source of heat, this affects the specific power of the heated room.

The cable laying step is calculated as follows: the required specific heating power is multiplied by 100 and divided by the cable power.Calculations are made in such a way that subsequently the cable is not cut (this is strictly prohibited). When using a single-core wire, it must be taken into account that its end must return to the beginning of the installation, thereby increasing its length. For laying heating mats, the cable pitch does not require calculations. The power of the system is calculated according to the heating area.

Wiring check

Electric underfloor heating for tiles involves a large energy consumption. Before installing it, it is necessary to check whether the existing wiring is suitable for the new load. If, when calculating the cable cross-section, it turns out that the diameter of the core does not meet the requirements, it is replaced. It is forbidden to connect the heating system to the socket. The best option is to conduct an additional electrical wiring line to the shield.

When designing electrical wiring, the power of household electrical appliances is taken into account. If the power consumption exceeds 2 kW, they must be connected to separate machines. To protect electrical insulation, an RCD device is used, which operates at a rated current of up to 30 mA. In rooms with high humidity, grounding conductors are used, connected to large metal objects.

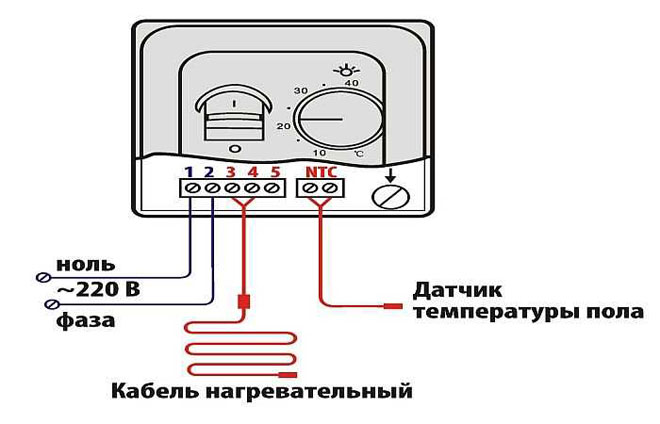

Mounting the temperature sensor

Particular attention should be paid to the rules for connecting the thermostat and temperature sensor. The thermostat is the control unit of the electric floor and processes information from the heat sensor, turns off and turns on the heating. The controller can be programmable or without a program installed; it is mounted on the wall at a height of about a meter in an accessible place.

The cable connecting the regulator to the heating system is laid in a corrugation and a special pipe. The wire from the thermostat is connected to a heat sensor installed at a distance of up to 40 cm from the wall between the cable turns. The corrugation must be laid without kinks; its edge of connection with the heating system is insulated with a sealant to avoid the penetration of the mortar used in the screed. The temperature sensor is also placed in the corrugation to provide access to it if repairs are necessary.

Laying cable or thermomat

Before starting the installation of a cable underfloor heating, it is necessary to measure the resistance of the cable. The cable is laid with a snake at a distance of a calculated step (at least 10 cm) using a special fastening tape. Sometimes a reinforcing mesh is installed, to which a cable is attached with plastic clamps. Mounting strips with holes can be used to reinforce the cable snake. From the walls you need to retreat up to 20 cm.

When laying a single-core wire, it is necessary to lead its end to the initial installation site, without crossing other turns. In a two-core cable, one wire serves as a heat source, the second closes the circuit, so a coupling is made at the end of the cable. The cable is mounted after preparing the surface, laying thermal insulation (if necessary, waterproofing) and a small layer of concrete screed. Sometimes the cable is laid directly into the concrete screed. The heating surface contour is assembled perpendicular to the wall on which the thermostat is located.

Mesh thermomats consist of a thin cable fixed on a fiberglass mesh.Mats can be installed without prior concrete screed, laying them in tile adhesive, increasing its thickness to 10 cm. Mats with an elastic base can be stretched with a complex configuration of the heating circuit.

Heating mats are laid easier than the cable method: there is no need to calculate the pitch between the turns, the cable bend is excluded. Nevertheless, you need to know how to properly lay a warm floor under the tiles in this way. The mats must be attached to the thermal insulation layer with adhesive tape, keeping the distance between the heating fragments up to 10 cm and retreating about 20 cm from the wall. When making turns, the mats can be cut without touching the cable and perform the necessary turns. After installation, the electrical system must be checked for resistance.

Pouring screed and laying tiles

The laying of the electric underfloor heating is completed by applying a protective layer. It can be a concrete floor screed or self-leveling floor. Most often, a special adhesive mixture is used for direct laying of ceramic tiles. The thickness of the screed or adhesive layer should be from 3 to 5 cm. Sometimes the adhesive layer is applied twice: first, the mats or cable loops are closed, then the next layer is applied to lay the tiles.

Adhesive for ceramic tiles should be designed for warm substrates, such mixtures are sold with special markings or indicating the operating temperature range. Applying glue to the heating part should not provoke mechanical damage and air voids. The layer of tile adhesive should be 3 times the diameter of the heating wire.You can operate the floor when the screed and glue are completely dry.

Similar articles: