Comfortable air temperature should always be maintained in the house. Often, underfloor heating is installed for these purposes. It is not always possible to install electric or water heating. Great alternative - infrared film underfloor heating.

Content

What is infrared film underfloor heating

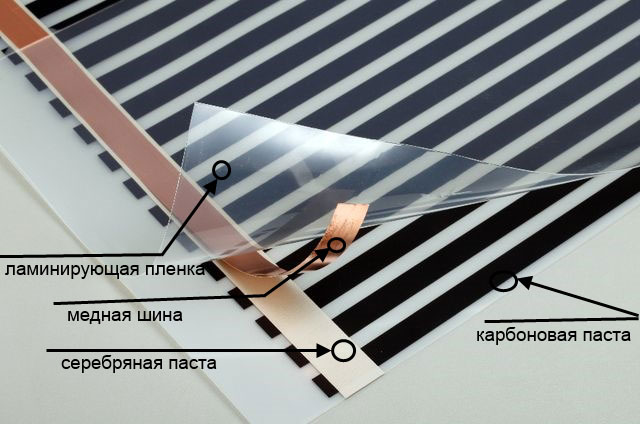

Infrared film coating is a roll material. This is a carbonate paste that is sealed in a polyester or polypropylene film. Special conductive tires are installed along the edges. Most often these are strips of silver and copper. It is through them that the electric current is transmitted. After it passes through carbon fiber, heat is released.

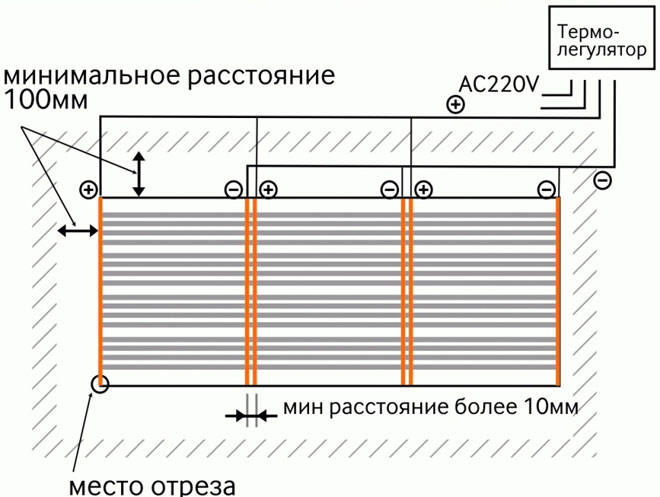

Conductive strips are assembled in sections, between each of them there is a dividing strip. It is convenient to cut material on it.The advantage of such a system is that if one lane fails, then all the others will continue to work.

REFERENCE. Single roll width underfloor heating film kit can vary from 50 cm to 1 m. The thickness of the film is from 0.2 to 2 mm.

Film floor types are safe for human health. Infrared warm floor does not generate electromagnetic waves. Due to the heating of the furniture, the air temperature in the room is lower, but at the same time it is quite comfortable. When objects are heated, there is no movement of air, so dust does not rise. This minimizes the risk of developing an allergic reaction. This type of flooring is completely neutral. It does not create any noise, chemical and mechanical influences.

Principle of operation

When the infrared carbon floor is turned on, current passes through the radiocarbon bands. Such a film floor consists of two layers. The first is a film, and the second contains heating elements. Most often it is nanocarbon paste. It is applied to the film in the form of even or curved stripes. A floor with even strips of heating elements will cost more.

When turned on, the coating heats up evenly. First of all, it is not the air that warms up, but the objects in the room. The efficiency of this type of heating depends on the correct layout of the room. If the design of the room is incorrect, then overheating of the furniture and walls is possible.

The principle of operation of infrared waves can be compared with the action of an air ionizer, which eliminates unpleasant odors and bacteria.

Types of films and their characteristics

Most infrared films have the same principle of operation.However, different types of film coating are intended for different types of premises. Depending on the maximum heating temperature, the following types of flooring are distinguished:

- high temperature IR film;

- low temperature;

- universal.

High-temperature types of infrared underfloor heating are great for laying under tiles. The maximum heating temperature is 50°C.

Low-temperature infrared floors can be combined with laminate, linoleum and other heat-sensitive coatings. In this case, the system warms up to 27 °C.

There are also a number of universal systems that can be combined with any floor covering. They are the most popular, as the buyer does not need to bother with the compatibility of coatings.

The second classification option is according to the type of heating element. There are several types:

- carbon;

- bimetallic.

When choosing a warm floor, you must also pay attention to the specific power indicator. According to this characteristic, 3 main types of infrared films are distinguished:

- weak - 130–160 W / m²;

- medium - 170 and up to 220 W / m²;

- high - above 220 W / m².

A film with low power is used in small rooms. It is best combined with light floor coverings. Coatings with medium power are installed in medium-sized rooms. Great option for tiles and porcelain tiles. Films with high power are mounted in large rooms. For example, it could be a sauna or a workshop.

Popular manufacturers

There are many different manufacturers of infrared film underfloor heating. The most popular include:

- Devi;

- Hemstedt;

- Nexans;

- Electrolux;

- heat plus;

- Teplolux;

- Thermo;

- RexVa.

South Korean companies Seggy Century Co, Geosung Ark, Sam Muyung Tech are quite popular. The peculiarity of these companies is that they give a guarantee for all their products for a period of 50 years.

Benefits of infrared floor

The main advantage of the infrared floor is a long period of operation. Other features include the following:

- no need to create a concrete screed for installation;

- installation in a few hours;

- compatibility with almost all types of flooring;

- minimum film thickness, which does not affect the calculated thickness of the floor finish;

- low heating inertia;

- the ability to use in offices, gyms and public places;

- uniform heating of the room;

- the ability to connect to the "smart home" system;

- minimum power consumption;

- no negative impact on human health.

In a room with such heating, the air does not dry out, maintains a comfortable level of humidity. The process of installation and dismantling is simple. If necessary, the floor can be dismantled, and the film can be used in another room.

Disadvantages of infrared floor

Film floors have a large number of hidden contacts. Before laying the floor covering, it is necessary to check the functionality of the installed system.

Other disadvantages of the infrared floor include the following characteristics:

- work from the network 220V;

- inexpediency of using such a heating system as the main one;

- the placement of infrared heaters should not be blocked by equipment or furniture;

- the need to create an intermediate layer with high strength when installing a soft floor covering.

Working from the network is a potentially dangerous factor. Despite the fact that there is a ground connection, as well as an automatic shutdown system, there is a risk of electric shock.

REFERENCE. An infrared floor is not as economical as a water floor.

A particularly large gap in the cost of heating is obtained if natural gas is used to operate the water floor. Such a source of heating is recommended to be used as an additional one.

Before laying soft flooring, an additional durable layer must be created. For this, plywood, fiberboard and chipboard can be used. Creating an additional coating not only improves strength, but also increases financial costs.

All the disadvantages of such a floor can be eliminated with proper planning, competent calculations and installation.

Where are film systems used?

The infrared film floor has a wide range of applications. Such material is used as the main or additional heating:

- residential premises;

- public buildings;

- industrial facilities;

- agricultural buildings.

Often infrared film is used for additional heating of an apartment or house. It can be combined with any floor covering. As the main source of heat, such a system is used in rooms where there is no stationary heating or for the period between seasons.

This type of underfloor heating can be used as temporary or emergency heating.

REFERENCE. The film can be mounted not only on horizontal, but also on vertical or inclined surfaces.

If necessary, such material can be easily dismantled and moved to another location. If the dismantling area is small, it will take several minutes.

An infrared film floor is a great option for heating a public or industrial building. It can be used for additional heating:

- kindergarten;

- hotels;

- hospitals;

- schools;

- sports hall.

By connecting a special control panel, you can control the temperature in different rooms at the same time. Such heating systems are recommended for use in greenhouses and livestock facilities. Often infrared film is used for heating a winter garden or a greenhouse. It is also a great option for a poultry or pig farm.

With the help of an infrared film floor, you can warm up a small room well and maintain the optimum air temperature in a large room. This is a good alternative to a water floor or conventional heaters.

Similar articles: