Each electronic device that is included in the network needs protection against exceeding the threshold values of current or voltage. Various fuses and circuit breakers are used for current protection, but varistors are most often used to protect the device from overvoltage. In this article, we will consider the principle of operation of the varistor, its characteristics, advantages and disadvantages of this electronic component.

Content

What is a varistor and where is it used

Varistor - This is a variable resistor made of semiconductor material, which is able to change its electrical resistance depending on the voltage applied to it.

The principle of operation of such an electronic component differs from a conventional resistor and potentiometer. Standard resistor has a constant value of resistance at any time, regardless of the voltage in the circuit, the potentiometer allows you to change the resistance manually by turning the control knob. But the varistor has a non-linear symmetrical current-voltage characteristic and its resistance depends entirely on the voltage in the circuit.

Due to this property, varistors are widely and effectively used to protect electrical networks, machines and equipment, as well as electronic components, boards and microcircuits, regardless of the type of voltage. They have a low manufacturing cost, are reliable in use and are able to withstand high loads.

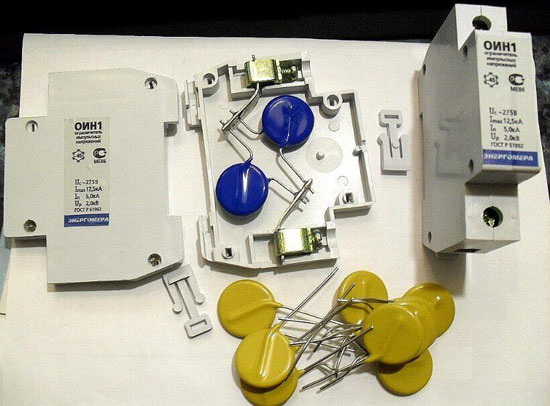

Varistors are used both in high-voltage installations up to 20 kV and in low-voltage installations from 3 to 200 V as a voltage limiter. At the same time, they can work both in networks with alternating current and with direct current. They are used to regulate and stabilize current and voltage, as well as in surge protective devices. Used in the design of network filters, power supplies, mobile phones, SPD and other SPEs.

Types and principle of operation

When operating under normal conditions, the varistor has a huge resistance, which can decrease when the voltage exceeds a threshold value. That is, if the voltage in the circuit increases significantly, then the varistor passes from an insulating state to an electrically conductive state and, due to the avalanche effect in the semiconductor, stabilizes the voltage by passing a large current through itself.

Varistors can work with high and low voltage and, accordingly, are divided into two groups of devices that have the same principle of operation:

- High-voltage: capable of operating in circuits with current values up to 20 kV (used in protective systems of networks and equipment, in surge protection devices).

- Low voltage: rated voltage for this type of components varies from 3 to 200 V (used to protect electronic devices and equipment components with a current of 0.1 - 1A and are installed at the input or output of the power source).

Varistor response time at power surge is about 25 ns, which is an excellent value, but in some cases insufficient. Therefore, manufacturers of electronic components have developed a technology for manufacturing an smd resistor, which has a response time of 0.5 ns.

Varistors of all types are made of silicon carbide or zinc oxide by sintering this material with a binder (resin, clay, glass) at high temperature. After receiving a semiconductor element, it is metallized on both sides with soldering of metal leads for connection.

Marking, main characteristics and parameters

Each manufacturer of varistors labels its product in a certain way, so there are a fairly large number of designation options and their interpretations. The most common Russian varistor is K275, and popular foreign-made components are 7n471k, kl472m and others.

The designation of the CNR-10d751k varistor can be deciphered as follows: CNR – metal oxide varistor; d - means that the component is in the form of a disk; 10 is the diameter of the disk; 751 – response voltage for this device (calculation occurs by multiplying the first two digits by 10 to the power equal to the third digit, that is, 75 times 10 to the first degree, we get 750 V); k - permissible deviation of the rated voltage, which is 10% in any direction (l - 15%, M - 20%, P - 25%).

The main characteristics of varistors are the following parameters:

Classification voltage is the voltage at certain values of the current flowing through the varistor (typically this value is 1mA). This setting is conditional and does not affect device selection;

Maximum allowable voltage – voltage range (RMS or RMS), at which the varistor begins to lower its resistance;

Maximum absorption energy - a characteristic showing the value of the energy that the varistor dissipates and does not fail when exposed to a single pulse (measured in joules);

Maximum surge current – normalizes the rise time and duration of the current pulse (measured in amperes);

Capacity is a very important parameter, which is measured with the closed state and a given frequency (drops to zero if a large current is applied to the varistor);

Tolerance - deviation from the nominal potential difference in both directions (indicated as a percentage).

Response time - the time interval for which the varistor goes from closed to open state (usually a few tens of nanoseconds).

Advantages and disadvantages of varistors

An important advantage of a non-linear resistor (varistor) is its stable and reliable operation at high frequencies and heavy loads. It is used in many devices operating with voltages from 3 V to 20 kV, it is relatively simple and cheap to manufacture and efficient in operation. Additional important benefits are:

- high response speed (nanoseconds);

- long service life;

- the ability to monitor voltage drops (inertialess method).

Despite the fact that this electronic component has a lot of advantages, it also has disadvantages that affect its use in various systems. These include:

- low-frequency noise during operation;

- component aging (loss of parameters over time);

- large capacitance: depends on the voltage and type of element, is in the range from 70 to 3200 pF and affects the performance of the device;

- at maximum voltage values, power is not dissipated - it overheats significantly and fails at long-term maximum voltage values.

Varistor selection

To choose the right varistor for a particular device, you need to know the characteristics of its power source: resistance and power of transient pulses. The maximum allowable current value is determined, among other things, by the duration of its exposure and the number of repetitions, therefore, when installing a varistor with an underestimated peak current value, it will quickly fail.In short, for effective protection of the device, it is necessary to choose a varistor with a voltage that has a small margin to the nominal.

Also, for the trouble-free operation of such an electronic component, the rate of dissipation of the absorbed thermal energy and the ability to quickly return to the state of normal operation are very important.

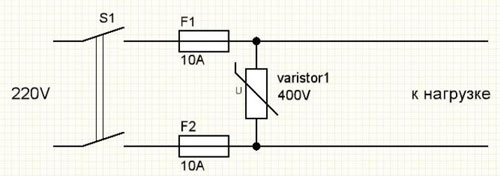

Designation on the diagram and options for connecting the varistor

On the schemes varistor usually denoted, just like a regular resistor, but with a U added next to the slash. This feature indicates in the diagrams that this element has a resistance dependence on the voltage in the circuit. Also on wiring diagram this element is marked with two letters R and U with the addition of a serial number (RU1, RU2 ... etc.).

There are a large number of options for connecting varistors, but the common thing for all methods is that this component is connected in parallel with the power circuit. Therefore, in the absence of dangerous values of voltage pulses, the current that flows through the varistor has a small value (due to large resistance values) and does not affect the system performance in any way. When an overvoltage occurs, the varistor changes resistance to small values, the load is shunted, and the absorbed energy is dissipated into the surrounding space.

Similar articles: