Many types of electrical capacitors do not have polarity and therefore their inclusion in the circuit is not difficult. Electrolytic charge accumulators are a special class, because. have positive and negative terminals, so when they are connected, the problem often arises - how to determine the polarity of the capacitor.

Content

How to determine the polarity of an electrolytic capacitor?

There are a number of ways to check the location of the plus and minus on the device. The polarity of a capacitor is determined as follows:

- by marking, i.e. according to the inscriptions and drawings applied to its body;

- in appearance;

- using a universal measuring device - a multimeter.

It is important to correctly determine the positive and negative contacts so that after installation, when voltage is applied, the circuit does not fail.

By marking

The marking of charge accumulators, including electrolytic ones, depends on the country, the manufacturing company and standards, which change over time. Therefore, the question of how to determine the polarity on a capacitor does not always have a simple answer.

Capacitor plus designation

On domestic Soviet products, only positive contact was indicated - with a “+” sign. This sign was applied to the case next to the positive terminal. Sometimes in the literature, the positive terminal of electrolytic capacitors is called the anode, since they not only passively accumulate charge, but are also used to filter alternating current, i.e. have the properties of an active semiconductor device. In some cases, the “+” sign is also placed on the printed circuit board, close to the positive terminal of the drive placed on it.

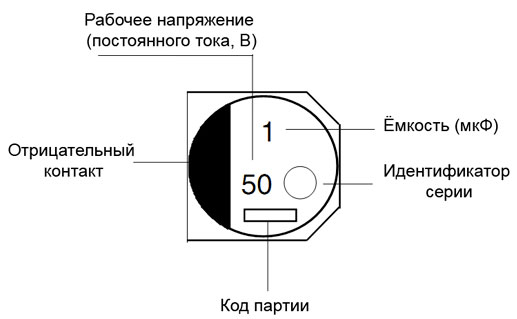

On products of the K50-16 series, the polarity marking is applied to the bottom, made of plastic. Other models in the K50 series, such as the K50-6, have a plus sign painted on the bottom of the aluminum housing, next to the positive terminal. Sometimes imported products made in the countries of the former socialist camp are also marked on the bottom. Modern domestic products meet global standards.

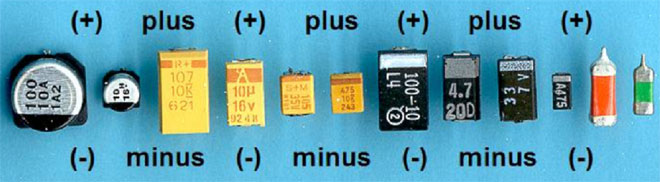

The marking of SMD (Surface Mounted Device) capacitors designed for surface mounting (SMT - Surface Mount Technology) is different from the usual one. Flat models have a black or brown case in the form of a small rectangular plate, part of which, at the positive terminal, is painted over with a silver stripe with a plus sign printed on it.

Minus notation

The principle of marking the polarity of imported products differs from the traditional standards of the domestic industry and consists in the algorithm: "to find out where the plus is, you first need to find where the minus is." The location of the negative contact is shown both by special signs and by the color of the housing.

For example, on a black cylindrical body, on the side of the negative terminal, sometimes called the cathode, a light gray stripe is applied along the entire height of the cylinder. The strip is printed with a broken line, or elongated ellipses, or a minus sign, as well as 1 or 2 angle brackets pointed at the cathode with an acute angle. Models with other denominations are distinguished by a blue body and a pale blue stripe on the negative side.

Other colors are also used for marking, following the general principle: a dark body and a light stripe. Such a marking is never completely erased and therefore it is always possible to confidently determine the polarity of the "electrolyte", as electrolytic capacitors are called for brevity in radio engineering jargon.

The case of SMD containers, made in the form of a metal aluminum cylinder, remains unpainted and has a natural silver color, and the segment of the round top end is painted over with intense black, red or blue and corresponds to the position of the negative terminal. After mounting the element on the surface of the printed circuit board, the partially painted end of the case, indicating the polarity, is clearly visible in the diagram, since it has a greater height compared to flat elements.

The polarity of the cylindrical SMD device corresponding to the marking is applied to the surface of the board: this is a circle with a segment shaded with white lines where the negative contact is located. However, it should be noted that some manufacturers prefer to mark the positive contact of the device in white.

By appearance

If the marking is worn out or unclear, then determining the polarity of the capacitor is sometimes possible by analyzing the appearance of the case. Many unwired, single-terminated containers have a longer positive leg than the negative leg. Products of the ETO brand, now obsolete, look like 2 cylinders stacked on top of each other: a larger diameter and a small height, and a smaller diameter, but significantly higher. The contacts are located in the center of the ends of the cylinders. The positive terminal is mounted at the end of the larger diameter cylinder.

For some powerful electrolytes, the cathode is brought to the case, which is connected by soldering to the chassis of the electrical circuit. Accordingly, the positive terminal is isolated from the housing and located on its upper part.

The polarity of a wide class of foreign, and now domestic electrolytic capacitors, is determined by the light strip associated with the negative pole of the device. If, however, the polarity of the electrolyte cannot be determined either by marking or by appearance, then even then the task of “how to find out the polarity of the capacitor” is solved by using a universal tester - a multimeter.

Using a multimeter

Before carrying out experiments, it is important to assemble the circuit so that the test voltage of the DC source (PS) does not exceed 70-75% of the nominal value indicated on the drive case or in the reference book. For example, if the electrolyte is designed for 16 V, then the power supply unit should produce no more than 12 V. If the electrolyte rating is unknown, the experiment should start with small values in the range of 5-6 V, and then gradually increase the voltage at the output of the power supply unit.

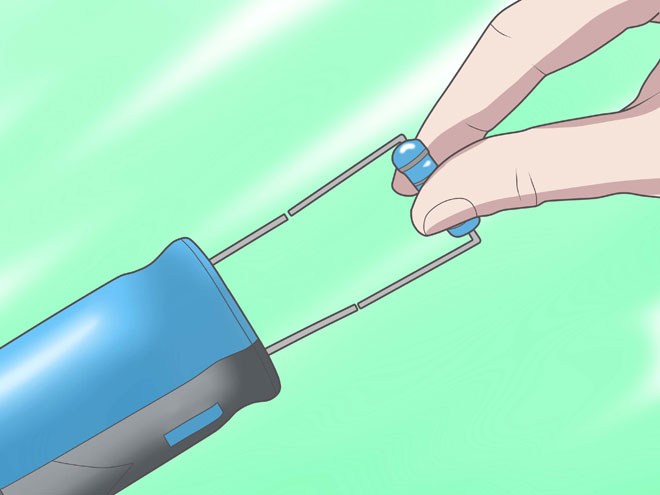

The capacitor must be completely discharged - for this you need to short-circuit its legs or leads for a few seconds with a metal screwdriver or tweezers. You can connect an incandescent lamp from a flashlight to them until it goes out or a resistor. Then you should carefully inspect the product - it should not have damage and swelling of the body, especially the protective valve.

You will need the following devices and components:

- IP - battery, accumulator, computer power supply or a specialized device with adjustable output voltage;

- multimeter;

- resistor;

- mounting accessories: soldering iron with solder and rosin, side cutters, tweezers, screwdriver;

- a marker for applying polarity signs to the body of the tested electrolyte.

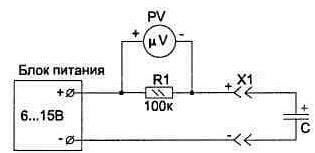

Then you should assemble the electrical circuit:

- in parallel with the resistor using "crocodiles" (i.e. probes with clips) connect a multimeter configured to measure direct current;

- connect the positive terminal of the power supply to the output of the resistor;

- connect the other terminal of the resistor to the capacitance terminal, and connect its 2nd terminal to the negative terminal of the power supply.

If the polarity of the electrolyte connection is correct, the multimeter will not record the current.Thus, the contact connected to the resistor will be positive. Otherwise, the multimeter will show the presence of current. In this case, the positive contact of the electrolyte was connected to the negative terminal of the power supply.

Another test method is different in that the multimeter, connected in parallel to the resistance, is switched to the DC voltage measurement mode. In this case, when the capacitance is connected correctly, the device will show a voltage, the value of which will then tend to zero. If connected incorrectly, the voltage will first drop, but then it will be fixed at a non-zero value.

According to method 3, a device that measures direct voltage is connected in parallel not with resistance, but with the capacitance being tested. With the correct connection of the poles of the capacitance, the voltage on it will reach the value set on the IP. If the minus of the IP is connected to the plus of the capacitance, i.e. incorrectly, the voltage across the capacitor will rise to a value equal to half the value supplied by the power supply. For example, if there is 12 V at the IP terminals, then there will be 6 V at the capacitance.

After the end of the checks, the container should be discharged in the same way as at the beginning of the experiment.

Similar articles: