LED strips - modern lighting devices that have firmly entered and entrenched in our lives. With their help, it became possible to perform not only illumination for decorative purposes, but also the device of full-fledged lighting in the premises of apartments and houses, industrial facilities and transport. They have low power consumption, lighting quality that is not inferior to standard lamps, and are conveniently mounted on any surface. This article will help you understand the whole variety of LED strips, their principle of operation, application and guide you on how to choose the right strip for any purpose.

Content

The principle of operation and the device of the LED strip

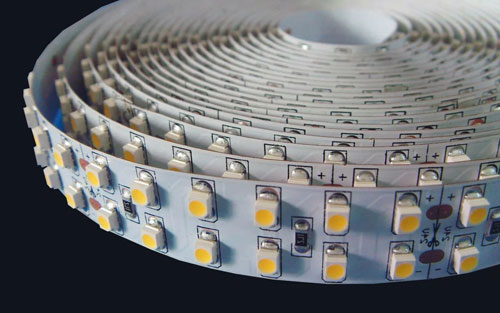

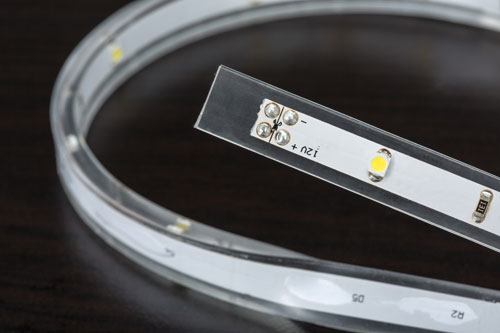

LED Strip Light - a light source, which is a board with LEDs equidistant from each other. The base of the tape is made of a dielectric material with a thickness of 0.2 to 0.5 mm; it contains conductive tracks and pads. LEDs and current limiting resistors are installed on these mounting pads on the tape. The main element that performs the useful work of emitting light is the LED. The principle of its operation is based on the electron-hole transition when an electric current is passed through the LED in the forward direction.

For operation, the tape is connected to a special transformer, which lowers the voltage from 220V to 12-36V. It can be made with or without a waterproof design and can have a special self-adhesive layer for quick installation.

Types of LED strips

Manufacturers of LED strips produce a large number of such devices, which differ in size, number of LEDs per meter and other technical characteristics. Also, tapes can be made in different colors, degrees of tightness and have different glow options.

Single color ribbons

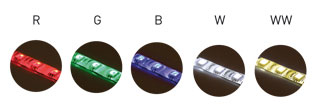

Single-color tapes are also called monochrome or SMD (from the English. surface mounted device surface mounted device). Such a tape can only shine in one color, depending on what color LEDs are installed on it. The most common and commonly used color is white. It is indicated by the English letter W and is cheaper than all other color options. Also popular are LED strips with red crystals (R), blue (B) and green(G) colors - since these colors are primary.

There are SMD tapes of intermediate shades, which are obtained using a special composition on the LED chip. Usually all intermediate colors shine less brightly than the primary ones.

Ribbons of different colors are often used for decorative lighting in the interior of rooms or street decor. White tape is used as additional lighting for workplaces and is also successfully used for interior decoration.

White ribbons have different glow temperatures, by analogy with energy-saving lamps, they can have cold or warm light.

Multicolor RGB Ribbons

Multi-color ribbons allow you to change the color of the glow using various controls. This effect is possible due to the multi-color LEDs mounted on the LED strip. The optical shift of red, green and blue colors gives a variety of shades of illumination.

Ribbon color management is carried out using special controllers that can transmit from 3 to 16 million shades. In addition, advanced models adjust the automatic color change depending on the user's preferences or preset algorithms.

RGB tape cannot produce pure white, therefore it is not used for additional or main lighting. But there is a kind of ribbon that, in addition to different combinations of the three primary colors (red, green and blue) can separately shine in white. Such tapes have the abbreviation RGBW (multicolor + cold white) or RGBWW (multicolor + warm white).

It is worth noting that multi-color ribbons are much more expensive than single-color ribbons, but their scope is limited only by the human imagination.

Open and sealed

LED strips can be produced both in waterproof and dustproof sealed design, and in open form.

The components of the open type LED strip are not protected from moisture and mechanical stress. Such a tape is used only in dry rooms as decorative lighting hidden in furniture or room structures. It is also used in conjunction with special protective housings for LED strips, which perform the function of external protection.

Sealed devices are protected from external influences using a special layer of silicone or other light-transmitting material that does not conduct electricity. The security class complies with the standard IEC 60529 and is assigned depending on the quality of protection against the penetration of objects and moisture.

Sealed LED strips are used in rooms with high humidity, as well as for street lighting of buildings and structures. Due to the protection against damage, they can be installed on stairs and other structures where mechanical impact on the tape is possible.

Ribbons "Running Fire"

Ribbon "Running Fire" - This is a special type of LED strip, in which you can change the color and brightness of each LED, regardless of the others. This is possible due to the special design of the board, which has addressable microcircuits for controlling lighting scenarios.

With the help of such a tape, special lighting effects are created that cannot be performed with conventional RGB tapes.They are used to decorate entertainment facilities and organize lighting at various holidays and events.

Side glow tapes

An LED strip that has a side glow looks like a standard strip, except that the LEDs are located on the end. Cylindrical-type LEDs are mounted at the ends of such a tape, and the effect of lateral light incidence with an angle of 120 degrees occurs.

Such tapes are used for decorative lighting, backlighting of TVs and various screens. Very often used by garage craftsmen when creating lighting in cars.

Main technical characteristics of LED strips

The difference between LED strips is expressed not only in their tightness and the color of the LEDs, but also depending on other technical parameters. To choose a tape that will best suit the tasks, it is important to know what characteristics you should pay attention to. The parameters include the supply voltage, the type and size of the LEDs used, the density of the LEDs on the tape, the length, the tightness class and other properties. Let's consider each of them in more detail.

Supply voltage

LED strips are most often 12, 24 or 36 volts. 12 volts use standard strips that do not have the high power and density of LEDs. More powerful devices operate with a voltage of 24 V, less often 36 V.

Regardless of what voltage (12 - 36 V) uses the device to work in standard 220 V electrical networks, they are equipped with special step-down transformers.If the mains voltage is applied directly to the LED strip, such a strip will naturally burn out. Therefore, when connecting LED devices, it is important to understand what voltage the connected tape works with.

Type and size of LEDs used

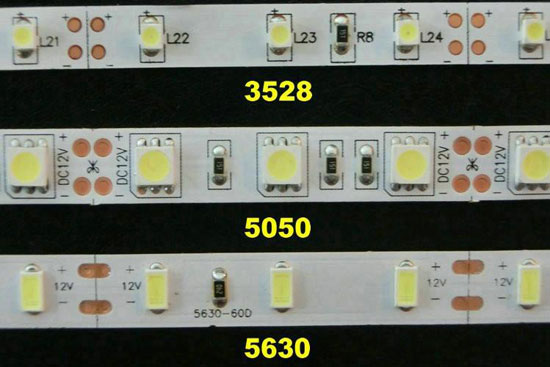

The type and size of the LEDs that are installed on the tapes are indicated by four-digit numbers. The first two digits indicate the length of the LED in millimeters, and the second - its width. In appearance, LEDs are:

• 3528 - have a small luminous flux (about 5 lm per LED) and are used for decorative purposes, as they do not shine brightly enough.

• 5050 (5060) - a common type of LED strip, which is characterized by a large size of LEDs and gives a glow of 12-14 lm for one LED.

• 2835 - a tape with such diodes is used to organize the main lighting, since they have a high brightness (about 25 lm), but in the decor such options are practically not used.

• 5630 - the brightest LEDs that are used to illuminate all types of premises. Diodes can deliver up to 75 lumens and get very hot during operation. To protect against overheating, they are mounted on special heat-removing plates made of aluminum or other heat-conducting material.

Density of placement of LEDs on the tape

The quality and brightness of lighting when using LED strips is related to the density of the LEDs. In other words, when buying an LED strip, you need to pay attention to the number of LEDs per linear meter of the strip. Standard products have a density of 30, 60, 90, 120 or 240 LEDs per meter of length.

Some manufacturers produce strip options with LEDs arranged in several rows.This is typical for LED strips such as "running fire" and other multi-colored strips.

The main rule here is obvious: the greater the density of LEDs on the tape, the higher the brightness of the tape and the greater the possibility of color management.

Degree of protection

The tightness of the LED strip is an important condition for installation in rooms with high humidity, swimming pools, as well as on the street. There is an indicator that indicates the degree of protection of the device from the penetration of moisture or dust into the device case or direct impact on electronic components. In the marking of the LED strip, it is indicated in English letters "IP” and two digits.

The first number indicates the degree of protection against dust and other particles, the second about the protection against water. The larger each number, the more significant the protection of the LED strip. Maximum protection against dust and moisture is indicated by the IP68 marking.

Based on the operating conditions of the tape, its degree of protection is selected. For example, in residential premises with normal humidity, IP20 tapes are used (that is, without protection), the IP55 class is suitable for the street, but in the pools they use IP67 or IP68.

Length

As a standard, LED strips are available in lengths of 5 or 10 meters. But, of course, there are ribbons in other sizes. The main rule: try to minimize the number of connections. For example, if you need to buy a tape 4 meters long, then it is better to buy 5 meters and cut off one meter from it than to buy two tapes of 2 meters each and then solder them together. For the price it will cost the same, but it will simplify installation.You can cut the tape along special cut lines so that the performance of the product does not suffer.

Deciphering the marking

All the necessary information about its technical characteristics is hidden in the marking of the LED strip. For example, LED-RGB-SMD5050/60 - IP67 will mean the following:

- LED - the light source is an LED;

- RGB stands for color. Maybe R - red, G - green, B - blue, RGB - color and W - white;

- SMD5050 - LED type and size;

- 60 - density of LEDs per meter;

- IP67 – degree of protection from dust and moisture.

Additionally, the marking may indicate the length of the tape, the glow temperature of the white tape and the supply voltage.

How to evaluate the build quality of an LED strip

When buying an LED strip in a store, you need to visually evaluate the quality of its workmanship. It should not have violations of the protective layer, consist of several tapes soldered together, look messy, and the LEDs should be distributed evenly throughout the tape.

If it is possible to connect the tape to power and check the quality of lighting, then it is worth evaluating the uniformity of the glow and the brightness of the tape. The color must correspond to that specified in the technical specifications. The power supply must have more power than the tape with a margin to avoid overheating and failure.