Fluorescent lamps are based on the glow of a gas discharge in mercury vapor. The radiation is in the ultraviolet range and in order to convert it into visible light, the bulb of the lamp is covered with a layer of phosphor.

Content

The principle of operation of a fluorescent lamp

A feature of the operation of fluorescent lamps is that they cannot be directly connected to the power supply. The resistance between the electrodes in the cold state is large, and the amount of current flowing between them is insufficient for a discharge to occur. Ignition requires a high voltage pulse.

A lamp with an ignited discharge is characterized by low resistance, which has a reactive characteristic.To compensate for the reactive component and limit the flowing current, a choke (ballast) is connected in series with the luminescent light source.

Many do not understand why a starter is needed in fluorescent lamps. The inductor, included in the power circuit together with the starter, generates a high voltage pulse to start a discharge between the electrodes. This happens because when the starter contacts are opened, a self-induction EMF pulse of up to 1 kV is formed at the inductor terminals.

What is a choke for?

The use of a choke for fluorescent lamps (ballast) in power circuits is necessary for two reasons:

- starting voltage generation;

- limiting the current through the electrodes.

The principle of operation of the inductor is based on the reactance of the inductor, which is the inductor. Inductive reactance introduces a phase shift between voltage and current equal to 90º.

Since the current-limiting quantity is inductive reactance, it follows that chokes designed for lamps of the same power cannot be used to connect more or less powerful devices.

Tolerances are possible within certain limits. So, earlier, the domestic industry produced fluorescent lamps with a power of 40 watts. A 36W inductor for modern fluorescent lamps can be safely used in power circuits of outdated lamps and vice versa.

Differences between a choke and an electronic ballast

The throttle circuit for switching on luminescent light sources is simple and highly reliable.The exception is the regular replacement of starters, since they include a group of NC contacts for generating start pulses.

At the same time, the circuit has significant drawbacks that forced us to look for new solutions for turning on lamps:

- long start-up time, which increases as the lamp wears out or the supply voltage decreases;

- large distortion of the mains voltage waveform (cosf<0.5);

- flickering glow with double the frequency of the power supply due to the low inertia of the luminosity of the gas discharge;

- large weight and size characteristics;

- low-frequency hum due to vibration of the plates of the magnetic throttle system;

- low reliability of starting at low temperatures.

Checking the choke of fluorescent lamps is hampered by the fact that devices for determining short-circuited turns are not very common, and using standard devices, one can only state the presence or absence of a break.

To eliminate these shortcomings, circuits of electronic ballasts (electronic ballasts) have been developed. The operation of electronic circuits is based on a different principle of generating a high voltage to start and maintain combustion.

The high voltage pulse is generated by the electronic components and a high frequency voltage (25-100 kHz) is used to support the discharge. The operation of the electronic ballast can be carried out in two modes:

- with preliminary heating of electrodes;

- with cold start.

In the first mode, low voltage is applied to the electrodes for 0.5-1 second for initial heating. After the time has elapsed, a high-voltage pulse is applied, due to which the discharge between the electrodes is ignited. This mode is technically more difficult to implement, but increases the service life of the lamps.

The cold start mode is different in that the start voltage is applied to the cold electrodes, causing a quick start. This starting method is not recommended for frequent use, as it greatly reduces the life, but it can be used even with lamps with faulty electrodes (with burnt filaments).

Circuits with an electronic choke have the following advantages:

- complete absence of flicker;

- wide temperature range of use;

- small distortion of the mains voltage waveform;

- absence of acoustic noise;

- increase the service life of lighting sources;

- small dimensions and weight, the possibility of miniature execution;

- the possibility of dimming - changing the brightness by controlling the duty cycle of the electrode power pulses.

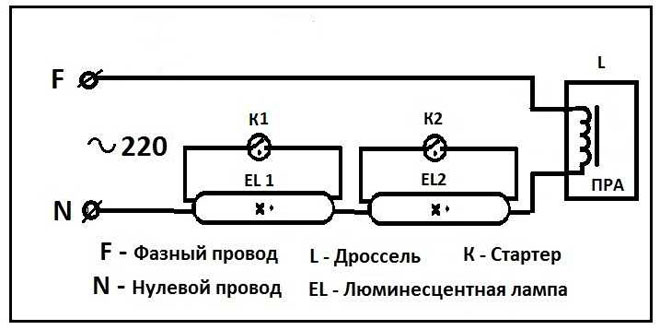

Classic connection via electromagnetic ballast - choke

The most common scheme for connecting a fluorescent lamp includes a choke and a starter, which are called electromagnetic ballasts (EMPRA). The circuit is a series circuit: inductor - filament - starter.

At the initial moment of switching on, a current flows through the elements of the circuit, heating the filaments of the lamp and at the same time the contact group of the starter. After the contacts are heated, they open, provoking the appearance of self-induction EMF at the ends of the winding of the electromagnetic ballast. High voltage causes a breakdown of the gas gap between the electrodes.

A small capacitor connected in parallel with the starter contacts forms an oscillatory circuit with the throttle.This solution increases the voltage of the start pulse and reduces the burning of the starter contacts.

When a stable discharge appears, the resistance between the electrodes at opposite ends of the bulb drops and the current flows through the inductor-electrode circuit. The current at this time is limited by the inductive reactance of the inductor. The electrode in the starter closes, the starter at this time is no longer involved in the work.

If the discharge in the flask does not occur, the process of heating and ignition is repeated several times. During this time, the lamp may flicker. If the fluorescent lamp blinks, but does not light up, then this may indicate its failure as a result of a decrease in the emissivity of the electrodes or a reduced supply voltage.

The connection of fluorescent lamps with a choke can be supplemented with a capacitor, which reduces network distortion. Also, a capacitor is installed in dual lamps for the mutual shift of headlights between adjacent lamps to visually reduce the flickering effect.

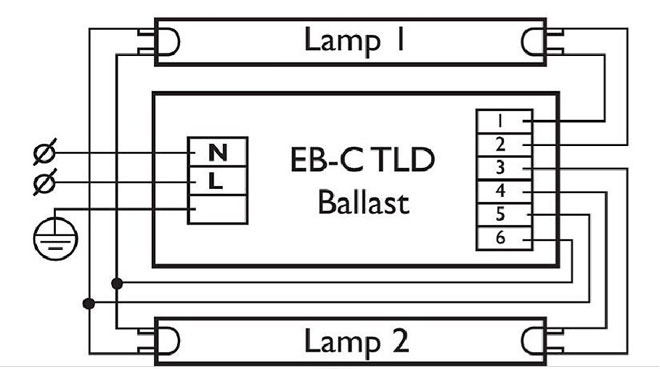

Connection via modern electronic ballast

In luminaires that use electronic ballasts for operation, the circuit for switching on fluorescent lamps is shown on the electronic ballast housing. You must follow the instructions exactly to turn them on correctly. This does not require any adjustment. A correctly assembled circuit with serviceable elements starts working immediately.

Scheme for serial connection of two lamps

Fluorescent lamps allow two lighting devices to be connected in series in one circuit under the following conditions:

- use of two identical light sources;

- electromagnetic ballast intended for such a scheme;

- choke, designed for twice the power.

The advantage of the series circuit is that only one heavy choke is used, but if one of the bulbs or the starter fails, the lamp is completely inoperative.

Modern electronic ballasts allow switching on only according to the above diagram, but many designs are designed to turn on two lamps. At the same time, two independent voltage generation channels are organized in the circuit, therefore, a double electronic ballast ensures the operability of one lamp in the event of a malfunction or absence of a neighboring one.

Connection without starter

Several options for switching on fluorescent lamps without a choke and starter have been developed. All use the principle of creating a high trigger voltage using a voltage multiplier.

Many of the circuits allow operation with burnt filaments, which allows the use of faulty lamps. Some solutions use DC power. This leads to a complete absence of flicker, but the electrodes wear out unevenly. This can be seen by the presence of dark spots of the phosphor on one side of the flask.

Some electricians install a separate start button instead of a starter, but this involves controlling the turning on of the lamp using a switch and a button, which is inconvenient and fraught with damage to the lamp if the button is pressed too long due to overheating of the electrodes.

Schemes for switching on fluorescent lamps without the use of a starter, with the exception of electronic ballasts, are not produced by the industry.This is due to their low reliability, a negative impact on the life of the lamps, large dimensions due to the presence of large capacitors.

Similar articles: