One of the most common inventions of Nikola Tesla is the Tesla transformer. The operation of this device is based on the action of resonant electromagnetic standing waves in coils. This principle formed the basis of many modern things: fluorescent lamps, TV kinescopes, charging devices at a distance. Due to the resonance phenomenon, at the moment when the oscillation frequency of the primary winding circuit coincides with the oscillation frequency of the standing waves of the secondary winding, an arc jumps between the ends of the coil.

Despite all the apparent complexity of this generator, you can make it yourself. The technology of how to make a Tesla coil with your own hands is contained below.

Content

Components and principle of operation

The Tesla transformer is assembled from a primary, secondary coil and a harness made up of a spark gap or interrupter, a capacitor and a terminal that serves as an output.

The primary winding consists of a small number of turns of heavy gauge copper wire or copper tube.It can be horizontal (flat), vertical (cylindrical) or conical. The secondary winding consists of a large number of turns of a smaller cross section and is the most important component of the design. It should have a length to diameter ratio of 4:1 and should have a grounded copper wire protective ring at the base to protect the unit's electronics.

Since the Tesla transformer operates in a pulsed mode, its design is characterized by the fact that it does not include a ferromagnetic core. This reduces the mutual induction between the windings. The capacitor, interacting with the primary coil, creates an oscillatory circuit with a spark gap included in it, in this case a gas one. The arrester is assembled from massive electrodes, and for greater wear resistance they are additionally equipped with radiators.

The principle of operation of the Tesla coil is as follows. The capacitor is charged through the choke from the transformer. The charging speed directly depends on the inductance index. When charged to a critical level, it will cause a breakdown of the spark gap. After that, high-frequency oscillations are generated in the primary circuit. At the same time, the arrester is activated, removing the transformer from the common circuit, closing it.

If this does not happen, then losses may occur in the primary circuit that adversely affect its operation. In the standard circuit, a gas discharger is installed in parallel with the power source.

Thus, the output Tesla coil can produce a voltage of several million volts. From such a voltage in the air, there are discharges of electricity, which have the form of coronary discharges and streamers.

It is extremely important to remember that these products generate high potential currents and are deadly to life. Even low-power devices can cause severe burns, damage to nerve endings, muscle tissue and ligaments. Can cause cardiac arrest.

Construction and assembly

The Tesla transformer was patented in 1896 and is simple in design. It includes:

- A primary coil with a winding of a copper core with a cross section of 6 mm², in an amount sufficient for 5-7 turns.

- A secondary coil made of a dielectric material and wires with a diameter of up to 0.5 mm and a length sufficient for 800-1000 turns.

- Discharger hemispheres.

- Capacitors.

- A protective ring made of copper core, as on the primary winding of a transformer.

The peculiarity of the device is that its power does not depend on the power of the supply source. The physical properties of air are more important. The device can create oscillatory circuits in various ways:

- using a spark gap arrester;

- using a transistor oscillation generator;

- on lamps.

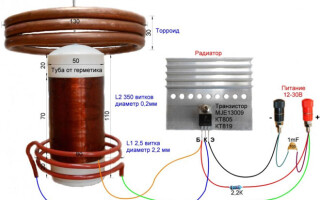

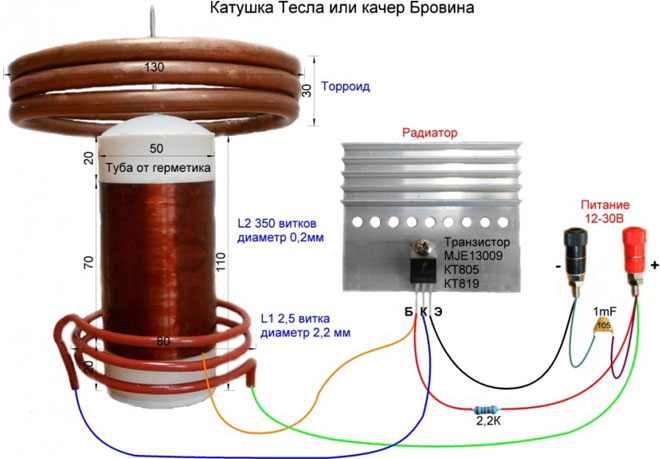

To make a Tesla transformer with your own hands, you will need:

- For the primary winding - 3 m of a thin copper tube with a diameter of 6 mm or a copper core of the same diameter and length.

- To assemble the secondary winding, you need a PVC pipe with a diameter of 5 cm and a length of about 50 cm and a PVC threaded fitting to it. You also need a copper, varnished or enameled wire with a diameter of 0.5 mm and a length of 90 m.

- Metal flange with an inner diameter of 5 cm.

- Various nuts, washers and bolts.

- Discharger.

- Smooth hemisphere for the terminal.

- The capacitor can be made independently. It will require 6 glass bottles, table salt, rapeseed or vaseline oil, aluminum foil.

- You will need a power supply that delivers 9kV at 30mA.

The Tesla transformer circuit is easy to implement. 2 wires with a connected arrester depart from the transformer. Capacitors connected in series are connected to one of the wires. At the end is the primary winding. A secondary coil with a terminal and a grounded protection ring is located separately.

Description of how to assemble a Tesla coil at home:

- The secondary winding is made by first fixing the edge of the wire at the end of the pipe. Winding should be even, avoiding wire breakage. There should be no gaps between the turns.

- When finished, wrap the winding at the top and bottom with masking tape. After that, cover the winding with varnish or epoxy.

- Prepare 2 panels for the bottom and top bases. Any dielectric material, plywood or plastic sheet will do. Place a metal flange in the center of the lower base and fasten it with bolts so that there is space between the lower and upper bases.

- Prepare the primary winding by twisting it into a spiral and fixing it on the upper base. Having drilled 2 holes in it, bring the ends of the tube into them. It should be fixed in such a way as to exclude contact between the windings and at the same time maintain a distance of 1 cm between them.

- To make an arrester, you will need to place 2 bolts opposite each other in a wooden frame. The calculation is made on the fact that when moving they will play the role of a regulator.

- Capacitors are made as follows. Glass bottles are wrapped in foil and filled with salt water. Its composition for all bottles should be the same - 360 g per 1 liter of water.Punch covers and insert wires into them. Capacitors are ready.

- Connect all nodes according to the scheme described above. Be sure to ground the secondary winding.

- The total number in the primary winding should be 6.5 turns, in the secondary - 600 turns.

The described sequence of actions gives an idea of how to make a Tesla transformer yourself.

Switching on, checking and adjusting

It is advisable to make the first start outdoors, it is also worth removing all household appliances away to prevent their breakdown. Remember the precautions! To start, do the following:

- They go through the entire chain of wires and check that no bare contacts touch anywhere, and that all nodes are securely fastened. A small gap is left between the bolts in the arrester.

- Apply voltage and observe the appearance of the streamer. In the absence of it, a fluorescent lamp or incandescent lamp is brought to the secondary winding. It is advisable to fix them on a dielectric, a piece of PVC pipe will do. The appearance of a glow confirms that the Tesla transformer is working.

- In the absence of glow, the conclusions of the primary coil are reversed.

If you don't succeed the first time, don't despair. Try changing the number of turns in the secondary winding and the distance between the windings. Tighten the bolts in the arrester.

Powerful Tesla Coil

A distinctive feature of such a coil is its size, the strength of the received current and the method of generating resonant oscillations.

It looks like this. After switching on, the capacitor is charged. Having reached the maximum charge level, a breakdown occurs in the arrester.At the next stage, an LC circuit is formed - a circuit formed by the series connection of a capacitor and a primary circuit. This creates resonant oscillations and high power voltages in the secondary winding.

At the same time, something similar can be assembled at home. For this you should:

- Increase the diameter of the coil and the cross section of the wire by 1.5-2.5 times.

- Make a terminal in the shape of a toroid. An aluminum corrugation with a diameter of 100 mm is suitable for this.

- Replace the DC source with an AC source that delivers 3-5kV.

- Make a reliable ground.

- Make sure your wiring can handle this load.

Such transformers can generate power up to 5 kW and create coronal and arc discharges. In this case, the maximum effect is achieved when the frequency of both circuits coincides.

Similar articles: