In the modern world, printed circuit boards are used in the manufacture of electronic circuits. Among them, for example, assembly units of electronic equipment. A multi-layer plate with new electronic elements has the property of integration. This characteristic allows you to reduce the size of electrical circuits and equipment for computing. The first printed circuit board appeared more than a hundred years ago.

Content

- 1 What is a printed circuit board

- 2 Making an electronic printed circuit board at home

- 2.1 What material will we use to make

- 2.2 Basic requirements for manufactured boards

- 2.3 Necessary tools and chemistry

- 2.4 We print the circuit board drawing on the printer

- 2.5 Preparing a solution for chemical translation

- 2.6 Cooking fiberglass

- 2.7 Translating the drawing

- 2.8 We charge a fee

- 2.9 Drilling holes

- 2.10 Board tinning

- 3 Etching solution recipes

What is a printed circuit board

The printed circuit board looks like a dielectric plate. An electrical circuit is located on the surface of the product. A dielectric plate is needed to connect electronic components. The pins of the board components are soldered to parts of the conductive pattern.

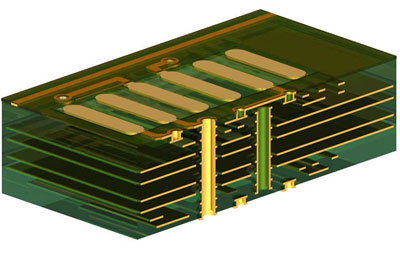

The drawing of the electrical circuit is made of foil on a solid insulating surface. To mount planar and output elements, special holes and platforms are made in the printed circuit board. The foil in the board is located on several layers, so vias provide electrical connection with it. The outer surface of the board is covered with a protective layer (solder mask) and marks (additional graphics and text according to the design documents).

Classification of printed circuit boards according to the number of foil layers with a pattern:

- unilateral;

- bilateral;

- multilayer (connection of several plates with one or two layers).

IMPORTANT! The number of layers is increased depending on the degree of complexity of the installation of the project.

Making an electronic printed circuit board at home

What material will we use to make

For printed circuit boards, dielectric foil bases are used. The material consists of multilayer plates with electrical insulation or synthetic fluoroplastic or polyimide films. On top of the insulation or film is copper, aluminum or nickel foil.

- Aluminum foil does not adhere well.

- Nickel foil has high resistance and low heat dissipation. In addition, its cost is more expensive.

- Copper foil lends itself well to soldering. Thickness - from 18 to 35 microns.

There are many materials available for the production of circuit boards.To make a plate with your own hands, you can use fiberglass or getinax:

- Fiberglass is a compressed material based on fiberglass. The composite material is impregnated with epoxy resin and lined with copper foil. Fiberglass has high thermal conductivity, strength and electrical insulation. The weight of the material will not make the assembled device heavier. The material is easy to machine. Application temperature varies from minus 60 to plus 125 degrees Celsius. The allowable thickness is 1.5 mm. At home, it is desirable to use 0.8 mm coated one layer.

- Getinaks - paper impregnated with bakelite varnish. Layers of material are obtained after pressing the paper in a hot way. Getinaks impregnated with epoxy resin. Application temperature varies from minus 65 to plus 120 degrees Celsius. The choice of variety Getinaks depends on the further operation.

Basic requirements for manufactured boards

- Rectangular, double sided.

- Thickness - no more than three millimeters (should correspond to the dielectric base).

- The contours of the recesses and grooves are located along the perimeter of the plate and do not coincide with the lines of the coordinate grid.

- The centers of all holes are located at the nodes of the grid.

- The gap between the edges of the hole and the board should not exceed the thickness of the latter.

- The pad size determines the hole diameter.

- The thickness of the tracks and the gaps between them is about 0.2 mm.

Necessary tools and chemistry

- fiberglass or getinaks;

- scraper for washing dishes;

- detergent for dishes;

- acetone;

- nail polish remover without acetone;

- technical or medical alcohol;

- old toothbrush;

- soft two-layer toilet paper;

- two-cube syringe;

- photographic paper;

- a laser black-and-white printer with a resolution of more than 600 dpi and a cartridge for it;

- sewing scissors;

- drills with a diameter of 0.6 mm, 0.8 mm and 1 mm;

- marker for drawing printed circuit boards;

- mini drill;

- hydroperite;

- lemon acid;

- rock salt (not iodized);

- plastic container for etching;

- a plastic card;

- cargo weighing 3 kilograms;

- alcohol rosin flux;

- Soldering Station.

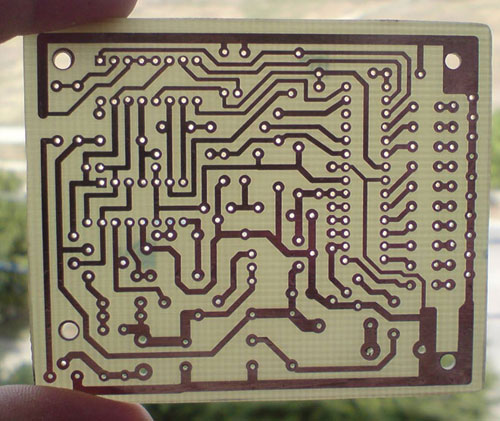

We print the circuit board drawing on the printer

- For the maximum thickness of the lines in the figure, in the printer properties, turn off the economical printing mode. It may be necessary to select a different mode for a good result. The graphic image of the board should not be smeared or worn.

- In the print settings, select the maximum resolution and black and white mode (if the printer is color).

- The scale must be realistic.

- After printing is completed, the image with graphic elements should not be touched by hand. It is better to leave a border on the sheet before cutting out the pattern. An additional two centimeters of area is enough to hold the paper with your fingers without touching the circuit.

IMPORTANT! When cutting, leave three millimeters from the border in order to see the edges when translating.

Preparing a solution for chemical translation

To make a chemical solution you will need:

- liquid without acetone and acetone itself in a ratio of 2: 1;

- syringe;

- glass container with rubber lid.

Both liquids are measured with a syringe, mixed and poured into a tightly closed container. If stored for a long time, acetone can evaporate and the substance will deteriorate.

Cooking fiberglass

- For fiberglass, you will need a wide, flat surface, in the center of which a sheet of toilet paper is placed.

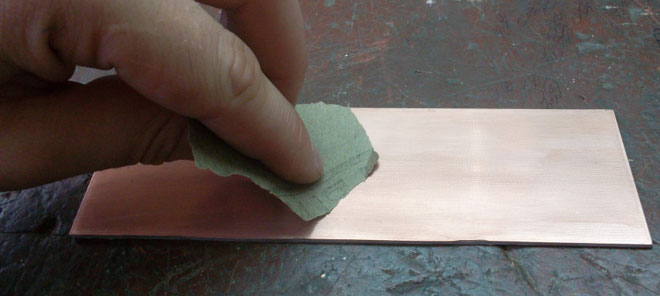

- The next step is to prepare the material. Fiberglass is rubbed with a metal sponge in a circle to remove oxidation, scratches and fingerprints. The plate should be shiny.

- Detergent is dripped into the center of the plate and foamed. In addition, the soap solution is applied to the hands.

- The board is washed for several minutes and rinsed with cold water. The plate should be held on the sides by the edges.

- After washing, the board is placed on paper. A couple of drops of acetone solution are applied on top and cleaned with toilet paper until completely dry.

IMPORTANT! Small fluff, dust or hair should not get on the surface of the board. Before the procedure, the room should be cleaned.

Translating the drawing

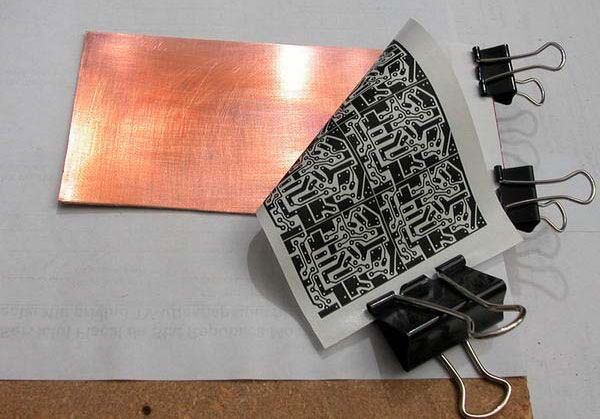

- Two milliliters of solution are drawn into the syringe.

- The payment is made on paper. There should be a surface of copper foil on top.

- A thin layer of liquid is applied to the copper surface, without gaps.

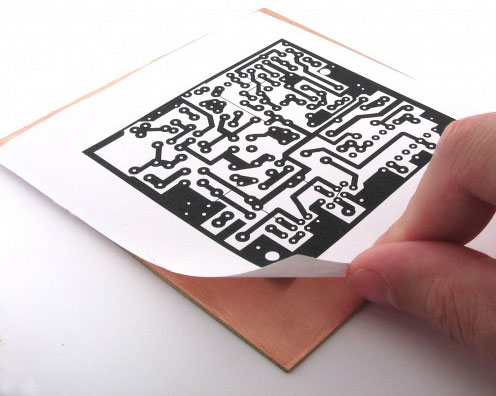

- Evenly on the plate put the drawing of the circuit with the seal down. Paper cannot be moved.

- With the help of a plastic card, paper is blotted and excess solution is squeezed out.

- After ten seconds, two pieces of paper are placed on top, after another ten seconds, a smooth press (3 kilograms) is placed on the plate and pressed for five seconds.

- Five minutes later, the cargo is removed. The printed paper should dry (become white).

- To remove the paper, the toothbrush is soaked in alcohol and the surface is moistened. After it has become oily, the paper is folded over from one edge, and alcohol is poured under it with a brush. The drawing area must be completely covered by the volatile liquid.

- The sheet is pulled evenly so that the paint remains on the plate. Alcohol should be added periodically.

IMPORTANT! If small areas of toner are left on the paper, you can use a marker to dot the gaps. It is advisable to paint in two layers to get the effect of black varnish. Before drawing a pattern on the board, measure the geometry of the drawing with a ruler.

We charge a fee

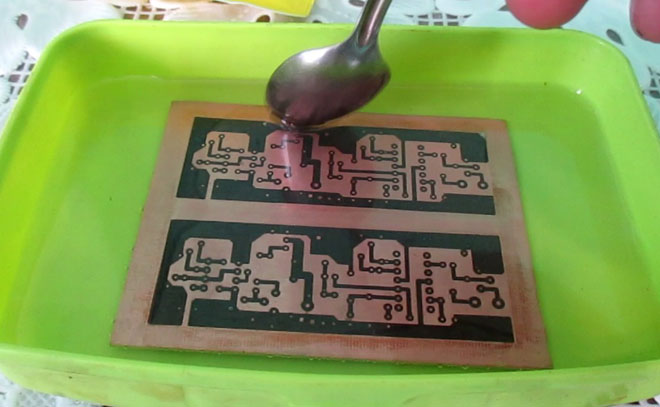

- To prepare the solution, pour 50 milliliters of warm water into a container.

- Three tablets of hydroperite are added to the water until completely dissolved. The result is hydrogen peroxide (3 percent).

- 15 grams of citric acid and 5 grams of salt are added to the liquid until completely dissolved.

- The solution is poured into a plastic container, the board is dipped into it with the circuit down for half an hour (sometimes forty minutes).

- The board is washed with warm water and the toner is washed with acetone. Top coated with alcohol-rosin flux.

Drilling holes

Holes are drilled in places where the track goes. The second holes are drilled when soldering the adapters. For greater rigidity, transitions are added along the edges of the plate. Since small diameter drills are used, a mini drill is needed.

Board tinning

By tinning the boards, the copper coating is protected from corrosion. The process requires a soldering station. For high-quality tinning, the soldering braid is put on the soldering iron tip and screwed with wire.

The plate and braid are coated with flux. Then tin is applied to the board. In the process, the copper villi from the braid are removed.

Etching solution recipes

Etching solution of hydrogen peroxide and citric acid

Ingredients:

- hydrogen peroxide (3%);

- lemon acid;

- salt;

- warm water (100 ml).

An etching solution with a volume of 100 milliliters is sufficient to remove copper foil (thickness 35 microns) from a plate area of 100 square centimeters. The prepared solution cannot be stored. Instead of citric acid, you can use acetic acid, but you will have to dry the board outside due to an unpleasant odor.

The advantages of the solution are low cost, easy availability of ingredients, high speed, safety. Etching can be carried out at room temperature.

Pickling solution based on ferric chloride

A solution based on ferric chloride is not demanding on temperature. Etching time is fast. However, the rate decreases as the consumption of ferric chloride in the liquid.

For cooking you will need: 200 milliliters of water and 150 grams of ferric chloride in powder form. The components are stirred until completely dissolved.

IMPORTANT! The pickling solution can be stored in a hermetically sealed container and used repeatedly. For re-use, it is “revitalized” with copper nails. The disadvantage of the solution is the high cost.

Etching solution based on hydrogen peroxide and hydrochloric acid

The etching solution is distinguished by its high procedure speed and availability. Hydroperite or hydrogen peroxide can be purchased at a pharmacy.

For preparation, a solution of hydrogen peroxide (3 percent) is poured into hydrochloric acid (while stirring it) in a thin stream. During the etching procedure, safety measures should be observed, since hydrochloric acid corrodes hands and spoils other objects. For this reason, the solution is not recommended for use at home.

IMPORTANT! Instead of hydrochloric acid, you can use a battery electrolyte to which salt is added.

Etching solution based on copper sulphate

Etching solution based on copper sulphate is rarely used, since the procedure is complex. In addition, copper sulfate is a pesticide that is used in agriculture to kill pests. The component is sold at retail outlets for gardeners and gardeners.

Method of preparation: copper sulphate (⅓ part) is mixed with common salt (⅔ part). Pour 1.5 cups of hot water into the mixture to dissolve the salt.

The time of the etching procedure with copper sulphate is about four hours. The required temperature is from 50 to 80 degrees Celsius. During etching, the solution must be constantly changed.

The method of making a printed circuit board at home is useful for beginners in the field of electronics. Before professional work, you can acquire the necessary skills at home. The number of methods is varied, which will affect the success of the plan.

Similar articles: