Soldering aluminum is a difficult process at home. The complexity is due to the properties of the metal, which make it difficult to connect individual parts of aluminum with other substances. It is necessary to connect aluminum in compliance with specially developed technologies that ensure the quality of soldering. What matters is the experience of the master, who connects aluminum parts by soldering.

Content

Why aluminum doesn't solder well

Many have tried to solder aluminum at home and understood well: the solder does not want to stick to the surface of the parts. This is due to the formation of a stable oxide film on the metal, which has low adhesion to the solder material. Methods for soldering aluminum at home are reduced to the fight against a protective film.

In mineralogy, aluminum oxide is called corundum. It consists of transparent crystals, which are precious stones.Corundum has a different color, depending on impurities: chromium gives a reddish tint, sapphire - bluish. The oxide film has high strength and cannot be soldered. It must be removed from the surface and then begin to solder the parts.

How to remove oxide film

The film is removed from the metal surface in several ways, the most effective are chemical and mechanical. Both methods require an airless environment in which there is no oxygen to work.

The chemical method is based on the deposition of zinc or copper on the surface of the billet by electrolysis. Copper sulphate is applied in the form of a concentrated solution to the place prepared for soldering. Attach the negative terminal of the battery or other power source to a clean area of \u200b\u200bmetal. One end of the copper wire is connected to the positive terminal, the other is lowered into the solution on the aluminum surface. As a result of electrolysis, copper or zinc is deposited in a thin layer on aluminum and adheres strongly to it. Now you can solder aluminum with tin.

An oil film is used to remove the oxide. For this method, it is better to take synthetic or transformer oil with a low water content. Other types of oils must be kept at a temperature of + 150 ... + 200 ° C, the water will evaporate. At higher temperatures, the contents will begin to splatter. The dehydrated oil is applied to the surface of the aluminum part. With sandpaper, you need to rub aluminum under the applied layer to remove oxide.

The emery skin is replaced with a scalpel, a serrated soldering iron tip or iron shavings obtained from a nail rubbed with a file. The chips are poured onto the oil and the tip of the soldering iron is rubbed over the surface, peeling off the oxide layer. It is advisable to heat a massive part with a hot air jet.Solder with a soldering iron is immersed in an oil droplet and rubbed at the place of soldering. For a better soldering process, rosin or other flux is added.

Fluxes based on acetylsalicylic or orthophosphoric acid, salts of boric or sodium acid have been created for soldering aluminum wires. Rosin is rarely used, it is ineffective in the case of aluminum. Fluxes are used for soldering wires, pots and other things.

Fluxes for aluminum brazing

Fluxes are highly active, so after soldering they must be washed off with a solution of water and alkali. The role of alkali is well performed by baking soda. After alkali, the junction is washed with clean water. Respiratory organs should be protected from flux vapors entering them. They can irritate mucous membranes and enter the bloodstream. The most common of them need to be considered individually.

Rosin

Rosin is the most sought after of all fluxes. It is used when joining various metals. It works on aluminum only in the absence of air, so it is rarely used. More time is spent working with rosin, less efficiency. This flux is not for professionals, it can solder, but the quality of the connection is not durable.

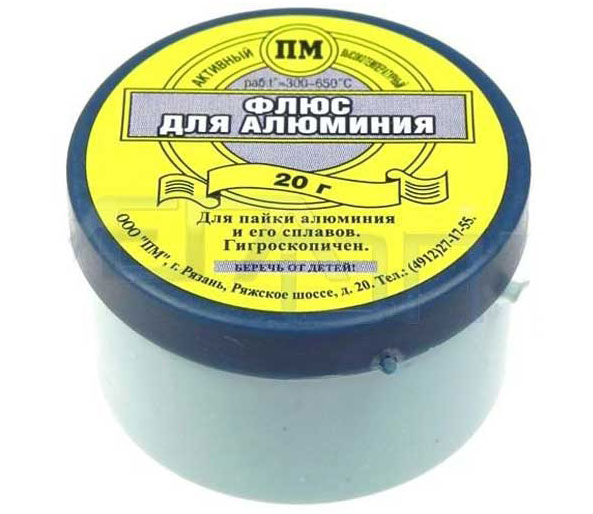

Powder flux

Aluminum is brazed with a gas burner using powder fluxes. It is not recommended to add oxygen to the flame, it reduces the efficiency of the flux. The most common fluxes:

- F-34A;

- borax;

- acetylsalicylic acid;

- solder fat.

F-34A is an active flux containing 50% potassium chloride, 32% lithium chloride, 10% sodium fluoride and 8% zinc chloride. The composition is used with solders containing chemical additives.It is hygroscopic and dissolves in water.

Borax is a powder that melts at 700°C, is soluble in water, and is washed off with an aqueous solution of citric acid. Differs in low cost.

Acetylsalicylic acid is found in the form of aspirin tablets. When heated with a soldering iron, vapors harmful to human health are released that burn the nose, eyes and respiratory organs.

Solder fat consists of paraffin, ammonium chloride and zinc, deionized water. Good soldering of pre-heated places that have undergone a tinning procedure. After soldering aluminum parts, it is recommended to wash off the flux residues, otherwise it causes corrosion of the metal.

Liquid flux

Liquid flux is applied to the place of soldering in a thin layer. When working with a soldering iron, it quickly evaporates with the release of burning fumes. Flux F-64 contains fluorides, tetraethylammonium, corrosion inhibitors and ionized water. It destroys the oxide film well and helps to solder large aluminum workpieces. It is used when soldering copper, aluminum, galvanized iron and other metals.

F-61 consists of triethanolamine, ammonium fluoroborate and zinc fluoroborate. Used for tinning and soldering aluminum alloys at temperatures up to 250°C. Castolin Alutin 51 L consists of cadmium, lead and 32% tin. Works most effectively at temperatures above 160°C.

Any of the listed fluxes helps to solder an aluminum pan, aluminum blanks of different sizes, to connect duralumin, duralumin (duralumin) blanks by soldering.

Solder for aluminum soldering

Solder for soldering aluminum is made on the basis of zinc or aluminum.Additives are introduced into it to achieve various characteristics: to lower the melting point, increase strength. They are produced in America, Germany, France, Russia. Let's consider some of them.

A common and widely advertised solder for aluminum is HTS 2000. It is produced by a company from the USA. Practice testifies to its fragility: soldered parts allow air and moisture to pass through. It cannot be used without flux.

Castolin 192FBK based on zinc (97%) and aluminum (2%) is made in France. Castolin manufactures 1827 and AluFlam-190 solders designed for brazing copper and aluminum at 280°C.

Castolin 192FBK is a solder tube containing flux in the core. It is produced in the form of bars, 100 g of which costs 100-150 rubles. Solders small holes and cracks well.

Chemet Aluminum 13 is a solder used when welding parts at 640°C and above. It is based on aluminum (87%) and silicon (13%). The melting temperature of the solder is about 600°C. It is produced in the form of bars, of which there are 25 pieces per 100 g. 100 g cost 500 rubles. A variety called Chemet Aluminum 13-UF has a hollow structure and contains flux in the core. Its cost for 12 bars, which weigh 100 g, is 700 rubles.

Aluminum solder is also produced at domestic enterprises. For soldering with a gas burner, the composition of brand 34A is used. It melts at a temperature of 525°C, soldered alloys AMts, AM3M, AMg2 well. 100 g cost 700 rubles.

Grade A consists of 60% zinc, 36% tin and 2% copper. Melts at 425°C. Produced in rods weighing 145 g. The cost of one rod is 400 rubles.

SUPER A+ is produced in Novosibirsk and is an analogue of HTS-2000. It is applied together with gumboil of the SUPER FA brand. It costs 800 rubles. for 100 g.In the molten state it becomes viscous, it is necessary to use steel tools to level it.

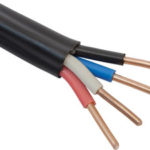

Cored wire

Fluxed wire is used when welding aluminum parts, it is not suitable for soldering. Welding of aluminum with a gas torch with a flux-cored wire is not carried out. It is better to weld parts with an electric machine.

Which soldering iron is suitable

What to solder, what tool is needed for this - it all depends on the soldering area. Aluminum and copper conduct heat well, so you need a powerful soldering iron. With a part area of 1000 cm², the power of the soldering iron is 50-60 watts. Often two or more parts are soldered, in which case the power increases to 100 watts. When heating the junction, a lower power soldering iron is suitable. The sting is chosen wide, notches can be made on it to remove the aluminum oxide film.

It is required to consider how to solder aluminum with a soldering iron. This is done with a well-heated tool after removing the oxide film and tinning, the solder adheres well to the tinned (tinned using special solders) area and any soldering iron is suitable

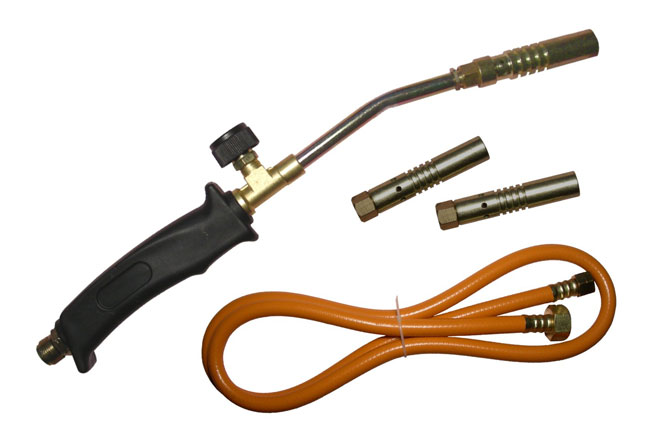

Aluminum brazing torches

You need to know how to solder with a gas torch. If the area of the parts is large and there is not enough soldering iron power, use a burner. It is better to use gas, because soldering aluminum with a gas burner has great potential. The burner quickly heats up the junction of parts almost to the melting temperature of aluminum. Flux with solder is applied to the connection, leveled with a soldering iron tip and hardens. The junction must be washed from the remnants of soldering acid or other flux.

When working with burners, fire safety rules must be observed. There must be no flammable liquids or materials nearby.

Which is better - welding or soldering

The answers to this question may vary. The use of one method or another depends on the use of parts after their connection. It is better to solder a car radiator. This method is cheap and reliable. Milk flasks and other food storage containers are best welded. The weld seam is more durable, especially for large sizes. Often it is necessary to weld parts made of aluminum alloys. Silumin welding is practically the only way to connect, apart from the use of glue.

On welding and soldering, if desired, you can make good money. Questions about how to solder aluminum tubes in a refrigerator or repair a bicycle frame come up frequently. In workshops, work is expensive: soldering pipes - 1000 rubles. and more. When connecting electrical wires by soldering, they take 15 rubles. for each. Repair of a bicycle frame made of aluminum alloys using solders costs 500 rubles. Repair of the pan will cost 100 rubles. To these amounts should be added the cost of time and money for the delivery of products to the workshop and back.

To save this money, you need to learn how to solder yourself. To do this, you need to purchase a gas burner in the form of a can for 700-1000 rubles. and solder. You can learn surface treatment and suturing on an old car radiator.

Similar articles: