When calculating any electrical networks, such a concept as the cross-sectional area of \u200b\u200bthe conductor is used. This property directly affects the safety and durability of the entire system, so it is important that the calculated value of the cross-sectional area of the electrical conductor corresponds to the actual one. This article will consider methods for measuring the diameter of a conductor and its cross section, as well as other options for determining the characteristics of a wire.

Content

- 1 Methods for measuring wire diameter

- 2 How to find out the cross section of a wire by its diameter for a stranded or segmented cable

- 3 Correspondence table of wire diameter to its cross-sectional area

- 4 Formula calculation

- 5 Wire Diameter Calculator

- 6 How to find out the cable cross-section by appearance

Methods for measuring wire diameter

In order to calculate the cross-sectional area of a conductor, it is necessary to know its exact diameter. There are several ways to measure wire diameter. These include measurements:

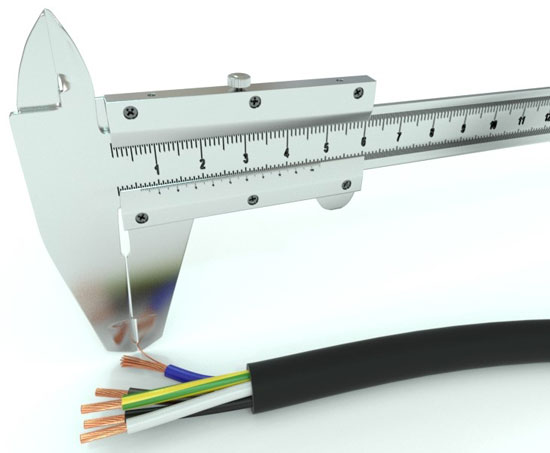

- With the help of a caliper: for this you need to understand the principle of operation of a caliper and be able to take readings from its scales. In this case, the use of an electronic measuring device makes it possible to simplify measurements - it will show the exact value of the diameter on its screen.

- Using a micrometer: The readings of this device are slightly more accurate than those of a mechanical caliper, but it also requires some skill to take correct and accurate readings.

- Using a regular ruler: this method is suitable for those who do not have such measuring instruments as a caliper or micrometer in their arsenal. Measuring the diameter of the conductor using a ruler will not be accurate enough, but it will be possible to roughly estimate the diameter.

To measure the diameter of the conductor, first of all, it is stripped with a knife or stripper from the insulation. Further, if a micrometer or caliper is used, the core of the wire is tightly clamped between the jaws of the device and the size of the conductor is determined on the scales of the device. When using a ruler, the insulation is removed at a distance of 5-10 cm and the core is wound around a screwdriver. The turns of the conductor should be pressed tightly against each other (approximately 8-20 turns). Next, the length of the wound section is measured and the resulting value is divided by the number of turns - a more or less accurate diameter value will be obtained.

How to find out the cross section of a wire by its diameter for a stranded or segmented cable

If determining the diameter for a solid conductor does not cause any problems, then measuring a stranded or segmented conductor can cause certain difficulties.

Measuring the cross section of a stranded wire

When determining the diameter of the core of a given cable, you cannot measure this size for all wires of the core at once: the value will turn out to be inaccurate, since there is space between the cores. Therefore, this cable must first be stripped of insulation, then fluff the stranded conductor and count the number of wires in the core. Further, by any method (caliper, ruler, micrometer), the diameter of one core is measured and the cross-sectional area of the wire is determined. After that, the obtained value is multiplied by the number of wires in the bundle and the exact size of the existing conductor is obtained.

Segment conductor measurement

Determining the dimensions of a segmented conductor is somewhat more difficult than measuring a round solid or stranded cable. In order to correctly estimate the cross-sectional area of such a conductor, it is necessary to use special tables. For example, to calculate the cross-sectional area of an aluminum conductor segment, determine the height and width of the segment and use the following table:

| Cable | Sectional area of the segment, mm2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 35 | 50 | 70 | 95 | 120 | 150 | 185 | 240 | ||

| Three-core sector single-wire, 6(10) kV | high | 5,5 | 6,4 | 7,6 | 9 | 10,1 | 11,3 | 12,5 | 14,4 |

| shire | 9,2 | 10,5 | 12,5 | 15 | 16,6 | 18,4 | 20,7 | 23,8 | |

| Three-core sector multiwire, 6(10) kV | high | 6 | 7 | 9 | 10 | 11 | 12 | 13,2 | 15,2 |

| shire | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 25 | |

| Four-core sector single-wire, up to 1 kV | high | – | 7 | 8,2 | 9,6 | 10,8 | 12 | 13,2 | – |

| shire | – | 10 | 12 | 14,1 | 16 | 18 | 18 | – | |

Correspondence table of wire diameter to its cross-sectional area

To quickly determine the cross-sectional area of \u200b\u200bthe conductor without making any calculations, tables of correspondence between the diameter of the core and its area are also used.

| Core diameter, mm | Cross-sectional area of the core, mm2 | Rated current for a core of a single-core and two-core cable, A | Rated current for a core of a three-core cable, A |

|---|---|---|---|

| 0,80 | 0,50 | 7,5 | 7,0 |

| 0,98 | 0,75 | 11,0 | 10,5 |

| 1,13 | 1,00 | 15,0 | 14,0 |

| 1,24 | 1,20 | 16,0 | 14,5 |

| 1,38 | 1,50 | 18,0 | 15,0 |

| 1,60 | 2,00 | 23,0 | 19,0 |

| 1,78 | 2,50 | 25,0 | 21,0 |

| 1,95 | 3,00 | 28,0 | 24,0 |

| 2,26 | 4,00 | 32,0 | 27,0 |

| 2,52 | 5,00 | 37,0 | 31,0 |

| 2,76 | 6,00 | 40,0 | 34,0 |

| 3,19 | 8,00 | 48,0 | 43,0 |

| 3,57 | 10,00 | 55,0 | 50,0 |

In this table, for convenient calculations and assessment of the conductive capacity of the core, the rated currents are indicated for each value of the cross-sectional area of \u200b\u200bthe conductor of a two-core and three-core electric cable.

Formula calculation

The main geometric indicator of a conductive core is its cross-sectional area. The capacity of the electrical conductor depends on this size, and, consequently, its operational characteristics, which affect safety and durability. As mentioned above, this parameter is easily determined after measuring the conductor diameter. To do this, use the formula to determine the area of a circle:

Ready-made tables are a great way to quickly determine the cross-sectional area of \u200b\u200bthe wire, but to be one hundred percent sure of the value obtained, it is better to check and calculate it yourself.

Wire Diameter Calculator

To quickly calculate the cross-sectional area of a round conductor, you can use a special calculator that is designed for this purpose and is able to quickly and accurately calculate the size of the conductive core using the formula above.

When using this online calculator, it is necessary to accurately measure the conductor diameter for a solid conductor or one of the wires of a stranded wire using a caliper, micrometer or ruler. For a stranded conductor, you will need to additionally calculate the number of wires.

How to find out the cable cross-section by appearance

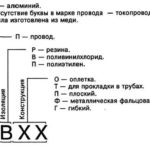

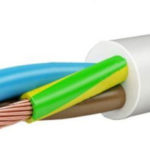

It is possible to determine the cable cross section without calculations. The cable in the factory version is necessarily marked: on its outer sheath, the manufacturer, the type of cable, the number of cores and the cross-sectional area of the conductive core are stamped with a certain step.

For example, if the cable has the designation VVG-ng-LS 3x2.5, then this means that the cable has an outer sheath and core insulation made of non-combustible PVC with no emission of hazardous gases during combustion, and such a cable also has 3 conductive cores with a cross-sectional area each conductor 2.5 mm2.

The marking does not always indicate the true value of the area of \u200b\u200bthe core, since compliance with this parameter remains on the conscience of manufacturers. This is due to the fact that most manufacturers do not adhere to GOST in production, but are guided by their own specifications in the production of cable products, which leads to a free interpretation of cross-sectional calculation methods and is not regulated properly. Therefore, it is best to check the conformity of its cross-section with the one stated in the marking before using the cable for its intended purpose.

Similar articles: