A fuse is an element of the electrical network that performs a protective function. Unlike a circuit breaker, after each operation, it needs to be replaced by a circuit-breaking part. A fusible link that burns out when the permissible value of the rated current is exceeded must be selected taking into account the load on the network.

Content

The principle of operation and the purpose of fuses

Inside the fuse insert is a bare metal conductor (copper, zinc, etc.) or alloy (become). Circuit protection is based on the physical property of metals to heat up when current flows. Many alloys also have a positive coefficient of thermal resistance. Its effect is as follows:

- when the current is below the nominal value provided for the conductor, the metal heats up evenly, having time to dissipate heat, and does not overheat;

- a large current strength will lead to heating of the conductor, while the fuse, designed for a certain value of current strength, will be destroyed.

The melting of a thin wire placed in an electric fuse is based on this property. Depending on the application, the shape and cross-section of the conductor can be different: from thin wire in household and automotive appliances to thick plates designed for a current strength of several thousand amperes (A).

The compact part protects the electrical circuit from overload and short circuit. When exceeding the allowable for the network (i.e. nominal) current, the insert is destroyed and the circuit breaks. You can restore its work only after replacing the element. When there is a defect in the connected equipment, the fuses will blow as soon as the faulty appliance is turned on, allowing the integrity of the appliance to be maintained and indicating a problem. If a short circuit occurs in the network, the protective device operates in the same way.

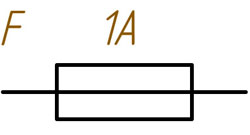

Conditional graphic designation on the diagram

According to the Unified System for Design Documentation of Russia, on the graphic diagrams of electrical circuits, fuses are indicated by a rectangle inside which a straight line runs. Its ends are connected to 2 parts of the chain before and after the protective device.

In the documentation for imported devices, you can also find other designations:

- rectangle with separated parts at the ends (IEC standard);

- wavy line (IEEE/ANSI).

Types and types of fuses

For use in electrical circuits, different types and varieties of PP are used. Products manufactured in Russia differ in the type of design:

- filled with marking PN-2; PPN, NPN, etc.;

- unfilled (PR-2).

The concept of fullness is associated with the presence inside certain types of inserts of a substance that extinguishes the electric arc that occurs at the moment of conductor burnout. The circuit will be opened only after it disappears. Therefore, flasks filled with PP contain quartz sand. Unfilled ones are capable of emitting gases that extinguish the arc. This occurs when the insert body material is heated.

In addition to types, there are types of software:

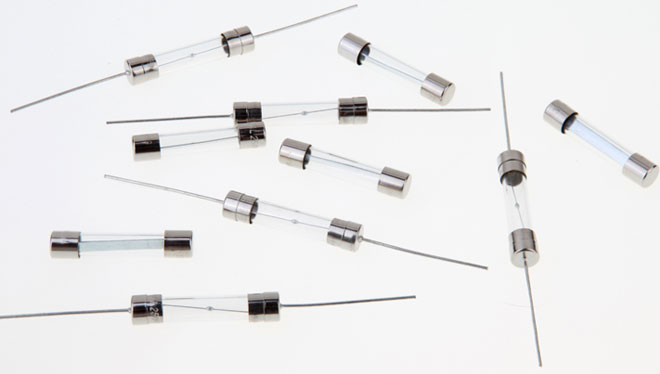

- low current used in low-power household appliances with a current consumption of up to 6 A. These are cylindrical inserts with contacts at the ends.

- Fork PP often put in cars. The name is due to the appearance: the contacts are on one side of the case and are inserted into the connectors, like a plug into a socket.

- Cork - electrical plugs for the meter common in single-phase networks. The rated current of such inserts is 63 A, they are designed for the simultaneous inclusion of several household appliances. The fuse insert in such a fuse is located inside a ceramic case with a cartridge, 1 contact remains outside, and the other is connected to the plug contacts. If the load is exceeded, the part burns out, completely de-energizing the apartment. You can restore the power supply by replacing the insert with a new one.

- Tubular PP in structure it resembles a plug insert, but its fastening is made between 2 contacts. The type of such a fuse is unfilled, and the body is made of fiber, which, when heated, releases gas.

- Knife fuses are designed for a current value of 100-1250 A and are used in networks where a high load is needed (e.g. when connecting a device with a powerful motor).

- Quartz, filled with quartz sand, are used in networks with voltage up to 36 kV.

- Gas-generating, collapsible and non-collapsible. During the combustion of varieties of PSN, HTP, a powerful release of gas occurs, accompanied by cotton. PP is used for networks with a voltage of 35-110 kV. The rated current of such a PP is up to 100A.

Depending on the total load on the network, different types of PPs are installed - more powerful ones are installed in special transformer boxes, they can withstand a current that meets the needs of a residential area or an enterprise. Low-power mounted in meters: they protect individual apartments. In old household appliances, PP can also be installed (low current), but modern technology rarely contains these elements.

Fuse link selection

The choice of fuses is made taking into account their ratings, time-current characteristics and the total load on the network (total power of all working elements). The rated current of the PP is the one that the fusible link can withstand before destruction. This value is indicated on the fuse box (e.g. marking 63 A for household cork fuses).

Time-current characteristics are calculated according to special graphs. They must be taken into account when connecting electric motors to the network, the starting current of which exceeds the operating current several times. When using multiple motors (at the enterprise) calculate the starting current of the most powerful.

The total (maximum) power of the network load is the sum of all the operating currents of the devices (indicated in the instructions and on the case). If the electric motor is connected to the network, then its starting current is also taken into account, divided by the coefficient k = 2.5 (for easy starting and squirrel-cage rotor) or 2-1.6 (for hard starting or phase rotors).

You can calculate the required denomination using the formula: I pp> 1 / k (I general + I start.). When calculating, it must be taken into account that the nominal value of the PP should always be greater than the value obtained in the current calculation.

In order not to waste time on calculations, select the rated current of the fuse-link according to the table.

| Tue | 10 | 50 | 100 | 150 | 250 | 500 | 800 | 1000 | 1200 | 1600 | 2000 | 2500 | 3000 | 4000 | 6000 | 8000 | 10000 |

| BUT | 0,1 | 0,25 | 0,5 | 1 | 2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 15 | 20 | 30 | 40 | 50 |

First line (Tue) indicates the power of the device indicated on its case, and the second (BUT) is the fuse rating. For a residential network, you will have to add up the W values \u200b\u200bof all household appliances and find a suitable number in the table, but it would be better to use circuit breakers.

Fuse Wire Diameter Calculation

Complicated calculations are made in order to temporarily repair a burned-out insert if it is not possible to replace it. In order for the network to be protected from overload, the thickness of the wire used to install the "bug" must correspond to the rating of the destroyed insert. For a network of a city apartment, where a PP with a nominal value of 63 A is installed, you can use a copper wire with a diameter of 0.9 mm.

If repair of another protective device is required, then you need to determine the rating of the PP (indicated on the case), and then determine the compliance of the existing copper wire:

- measure its diameter;

- cube this number and take the square root of the value;

- Multiply the resulting number by 80.

The result should be approximately equal to the nominal value of the PP indicated on the case.

When repairing, the selected wire is wound around the contacts of the burnt insert, connecting them. The bug is inserted into the socket on the fuse box.

If the wire melts again, then the fault is in the protected device or in the apartment network, and they must be repaired. Thicker wire must not be used, as this may cause a fire.

Health check

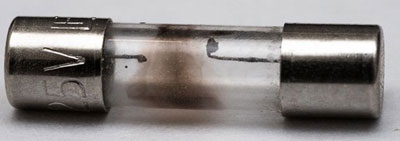

Modern automotive fuses sometimes have a built-in blown indicator. It informs the owner that the part needs to be replaced. In low-current PP, a wire is visible through a transparent case. But part of the PP is opaque and has no indicators.

If it is impossible to visually determine the conductor break inside the PCB, then its performance can be determined with a multimeter. Before checking the fuse with a tester, you need to select the minimum resistance value (Ohm). Attach the tester probes to the contacts of the PP and determine the readings of the device:

- at zero or close to 0 resistance value, a conclusion is made about the operability of the insert;

- if the tester shows 1 or an infinity sign, then the PCB burned out.

If the tester has a sound device, you can simply ring the fuse by attaching the probes to the contacts. The squeak of the tester indicates the health of the element.

Similar articles: