Most modern heating boilers have an electronic control system that monitors compliance with the specified parameters and ensures safety during operation. All domestic heating boilers, with rare exceptions, are powered by a standard 230V 50Hz power supply. Unstable operation of the power supply and power surges can pose a danger to the electronic "stuffing" of the device. To ensure reliable long-term operation of the boiler and protect it from possible problems with the power supply, a voltage stabilizer is installed. In this article we will analyze the issue of choosing the right stabilizer for your heating unit.

Content

Do you need a boiler stabilizer?

You can often hear the opinion that the presence of a voltage stabilizer is not so important. “My boiler has been working great without a stabilizer for ten years,” “it normally tolerates all the drops,” some owners say, implying that buying this device is a waste of money.

Indeed, modern devices cope with small voltage drops. Moreover, according to the interstate standard GOST 29322-2014, the mains voltage is not a constant value and should be 230 V plus or minus 10%. Accordingly, the range of 207-253 V falls under the standard voltage.

However, in real life, not everything always happens according to standards, and sharp jumps in parameters in the mains are not yet a fantasy. In addition, many different factors can cause possible problems, from weather conditions to human intervention. Therefore, the installation of a stabilizer still seems to be a justified solution, and its purchase in most cases is less expensive than repairing a heating boiler in case of an accident. In addition, many sellers define the installed SN as a prerequisite for the validity of the warranty.

What types of stabilizers are suitable for boilers

Manufacturers produce many stabilizers of various models. The devices on the market can be divided into four types:

- electromechanical (servo)

- relay

- electronic (thyristor)

- inverter

Each type has its own characteristics, pros and cons, which must be considered when choosing. Here is a brief overview of equipment for each type.

Electromechanical

The principle of operation is based on the circular windings of the transformer, along which carbon brushes controlled by a servo drive move.

Pros: low cost, wide input voltage range, accuracy and smoothness of regulation, ability to endure overloads, ability to work at low temperatures and high humidity, reliable overvoltage and overheating protection system, long service life.

Minuses: low adjustment (response) speed, increased noise level, increased weight and dimensions compared to other types of devices.

Important! It is strictly forbidden to install electromechanical stabilizers in rooms with gas equipment! This limitation is due to the fact that sparks can form during the operation of this type of SN. If gas escapes, it may cause an explosion.

Such stabilizers can be installed for heating boilers, but it is not recommended to use them if there are frequent perceptible power surges. Also, for safety reasons, a separate installation site is required.

Relay

Widespread modern type of stabilizers. Here, the current passed through the transformer winding is regulated by special relays, and not mechanically. Some resources provide information that relay MVs are not suitable for heating boilers due to their low speed. Indeed, the response speed of previously produced stabilizers of this type was low, but modern models do not have this drawback.

Pros: affordable cost, wide range and high speed of regulation, reliable protection system, compact size and light weight.

Minuses: step regulation, lack of power reserve, average noise level, short service life.

In terms of price / quality ratio, relay stabilizers are the best choice and are widely used with heating boilers.

Electronic

Electronic stabilizers also regulate the current by passing current through the transformer using electronic keys, which allows for the compact size of the device and its high efficiency.

Pros: wide range and high speed regulation, low noise, compact size, long service life.

Minuses: high cost, step regulation, lack of power reserve.

Electronic stabilizers are a more perfect and versatile solution for heating boilers. They have a higher cost than relay ones, so they are less common.

inverter

There is no transformer in inverter stabilizers, here the alternating input current is first converted to direct current, and then the necessary alternating voltage is generated from it.

Pros: wide range of input and high accuracy of output voltage, high speed and smoothness of regulation, no noise, minimal dimensions and weight, long service life.

Minuses: high cost, lack of power reserve.

Stabilizers of this type provide the highest quality regulation, but have the highest price among the listed types.

Read more about the different types of voltage stabilizers for the home, written in the following article: what types and types of voltage stabilizers for the home exist?

What characteristics of the stabilizer should be considered when buying

When selecting a voltage stabilizer, it is necessary to evaluate its key characteristics and their impact on the operation of the heating boiler.This will help you choose the model that is most suitable for your specific operating conditions.

Stabilizer Power

One of the main parameters for choosing a stabilizer for a heating boiler is power. You can find out how much power the boiler consumes in its passport. It is important not to confuse, for boilers, two values \u200b\u200bare usually indicated: the thermal power of the boiler (usually > 10 kW) and the electrical power we need (average 100-200 W or 0.1-0.2 kW).

When starting the boiler, the value may increase for a short time, the found parameter must be taken with a margin. We must also not forget about the related equipment that will possibly serve the stabilizer together with the boiler, it can be, for example, a circulation pump if it is not built into the boiler itself.

In addition, if the input current drops, then the ability of the stabilizer to increase it also falls, and voltage drop must also be taken into account. For example, if there is 170 V in the outlet, instead of the prescribed 230 V, the efficiency of the stabilizer will decrease to 80% of the rated power, i.e. a 500 W stabilizer must be calculated as a 400 W.

Thus, to calculate the required power of the stabilizer with a margin for starting current and drawdown at low voltage, we need to multiply the total power of the boiler and related equipment (if any) by a factor of 1.5. If the voltage in the network is very low, it will not be superfluous to increase the coefficient to 1.7.

Example: The power of the boiler is 150W, the circulation pump is 100W. We multiply their total power (250 W) by a factor of 1.7. We get the minimum power of the stabilizer 425 watts.

How much does the input voltage drop?

The stabilizer brings the voltage from the network to the required 230 V. Depending on the magnitude of the voltage drop in the network, stabilizers are produced with different input voltage ranges. To find out with what parameters we need a device, we need to make measurements.

To do this, you will need a voltmeter (multimeter). It is advisable to take measurements at different times of the day in order to see how the indicators change depending on the load on the network, while capturing the hours of maximum and minimum consumption (morning-afternoon-evening). It is better to write down the received data so as not to forget. It is advisable to take measurements within a few days. At the end, you can add 10-15 V to the peak values in each direction, this will provide a small margin.

If you got the values \u200b\u200bof 180-240 V, then it is with this range that a stabilizer is needed. In the private sector, outside the city, there may be more significant differences in the network, for example, from 140 to 270 V, which must be taken into account when buying.

The output voltage of the stabilizer is usually standard 230 V + -10%. To avoid problems due to lack of power, it is better to choose a stabilizer with an output voltage accuracy of no more than + -5%. This will ensure the parameters specified by the manufacturer and will be the key to long trouble-free operation.

Voltage stabilization rate

This parameter consists of two characteristics:

- regulation speed - measured in volts per second (V / s), shows the ability of the stabilizer to restore the standard output voltage with significant input deviations;

- response time - indicated in milliseconds, shows the response time of the device to a change in voltage.

The faster the speed and the shorter the response time, the better the stabilizer will protect your equipment.Good models have a regulation speed of 100 V/s or more. This indicator allows the stabilizer to restore the required voltage almost instantly. A speed of 15-20 V / s is considered not a very good value, which can lead to short-term incorrect operation of boilers that are especially sensitive to voltage.

An excellent response time is 5 ms or less. 10 ms will be quite acceptable, and 20 ms will be satisfactory. Larger values already imply some risk.

Important! Inverter regulators use double conversion, as mentioned above, so they do not have a response time parameter.

Availability of protection and restart function

Almost all modern models of stabilizers have a protection system that turns off the device if it is not able to ensure normal operation with a significant deviation in network parameters or, for example, overheats.

The voltage stabilizer for the boiler must have a restart function. What does this mean? When there are strong surges or a significant voltage drop, the device turns off the output power, which causes the boiler to turn off. The stabilizer monitors the network parameters and when they return to an acceptable range, the power is restored, the boiler starts up and continues to operate normally.

If there is no restart function, then a manual restart is required to reapply power. If the owners of the house are absent or away, in winter this can cause inconvenience and even lead to serious problems (defrosting and failure of the heating system and boiler).In very cheap models, the restart function may not be available, which is a big minus. Pay attention to this when buying a stabilizer.

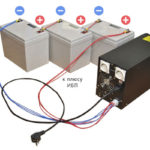

Design

Existing devices can vary greatly in weight and size, depending on their type. Available in wall and floor models, options with digital display and dial gauges. When choosing a stabilizer, do not forget to plan its installation location in advance, imagine how it will look in your interior, whether you want to hide it or, conversely, place it in a prominent place near the boiler. Do not make the common mistake of placing the stabilizer directly under the boiler, this is prohibited for safety reasons, if the water from the boiler leaks, it can flood the electrical appliance.

Popular Brands and Brands of Voltage Stabilizers

There is a wide variety of brands and models on the market, produced by both Western manufacturers and domestic companies that have long established production and often offer good options in terms of price / quality ratio. Popular brands on the market are Luxeon, Logic Power, Resanta, Energia, Progress, Ruself, Lider, Sven.

Examples of reliable boiler stabilizer models

Examples of good and reliable models of stabilizers for heating boilers by type.

Servo:

- Resanta ACH1000/1-EM;

- Luxeon LDS1500 Servo;

- RUCELF SDW-1000;

- Energy CHBT-1000/1;

- Elitech ACH 1500E.

Relay:

- LogicPower LPT-1000RV;

- Luxeon LDR-1000;

- Powercom TCA-1200;

- SVEN Neo R1000;

- BASTION Teplocom ST1300.

Electronic:

- Calm R 1200SPT;

- Luxeon EDR-2000;

- Progress 1000T;

- Leader PS 1200W-30;

- Awattom SNOPT-1.0.