Compliance with safety regulations when performing electrical work allows you to avoid traumatic situations associated not only with injury, but even with the death of an employee. According to the order No. 328n dated July 24, 2013 No. "On approval of the Rules for labor protection during the operation of electrical installations", a specialist starting to perform labor duties at electrical installations must be dressed in overalls and safety shoes made of polymeric materials.

Content

Why and in what electrical installations are dielectric boots and galoshes used?

The classification of the energy-technical group of equipment includes design features, power, type of use, current frequency, features of the operating room.

Design features allow subdividing the installations into:

- open, that is, located outside the premises;

- closed, located in the room itself;

- sheltered from snow or rain by a canopy.

According to the power value, they are divided into operating electrical installations up to 1000 V and over 1000 V.

Regardless of the type of power equipment, the use of overalls and footwear is essential. Their use allows you to protect a person from step voltage (voltage between two points on the surface of the earth, equal to the length of a person's step).

Important: dielectric galoshes are used when working in electrical installations up to 1000 volts; they are marked with the symbol En, denoting the protective properties of the item and the method of manufacture. Dielectric bots are used in any closed electrical installations (in dry weather it is permissible in open ones), regardless of the voltage class; they are marked with letters Ev.

The production of elastic products is subject to the requirements of GOST 13385-78 “Special dielectric footwear made of polymeric materials. Specifications".

How to use them

Before putting on boots or galoshes, you need to test them. The procedure is:

- test stamp verification;

- inspection of products for the presence of various mechanical damage;

- control over the preservation of the quality characteristics of the feedstock.

Varieties of special rubber shoes

Dielectric shoes include:

- bots;

- galoshes;

- boots.

Glued rubber galoshes

Glued galoshes are multi-layer products of an annular shape. They consist of:

- rubber top;

- similar grooved sole;

- a backdrop made of bumaz or twill;

- thick knitted lining;

- internal elements that create additional strength.

Rubber color - beige or light gray.

Important: when working in regions with a tropical climate, the textile material must be impregnated with an antiseptic.

Bonded rubber boots

Dielectric boots differ from galoshes by the presence of a lapel in the upper part. The flap is necessary to protect against the penetration of liquid.

The requirements for the production of bots are as follows:

- the height of the product must be at least 16 centimeters (including the wrapped collar);

- the thickness of the plantar part is not less than 0.6 centimeters;

- lining is necessarily made of a dielectric material.

Molded rubber boots

The production of molded models involves the manufacture of blanks from a specific rubber composition, their further assembly, molding and vulcanization. At the final stage, burrs, extrusion and other deviations from the norm are removed. Carry out the finishing of the entire product.

According to GOST 13385-78, uniform boots do not have internal reinforcing parts and textile lining. Lapels are present, as in adhesive products.

Molded rubber boots made of PVC

The boots are made up of:

- shaft, narrower at the bottom and expanded at the top;

- corrugated soles with heels made of polymeric material (rubber or PVC);

- inner textile lining.

Important: regardless of the type of footwear, the material used should not contain foreign hard and soft foreign bodies and bubbles (with the exception of the toe part), exfoliated elements, protrusion of rubber or PVC through the lining fabric, delamination of individual internal parts and other errors.

Main technical parameters and dimensions

The most important technical parameters of shoes include the width of the tops, the height of the boots and the bot. All characteristics are specified in GOST 13385-78.

Electrically resistant shoes have the following size range:

- men's galoshes - 240-307;

- women's galoshes - 225-255;

- bots (both male and female) - 292-352;

- men's boots - 247-307;

- women's boots - 225-270.

The size inside the product is not regulated by regulatory documents, it corresponds to the block and is not checked during testing.

If you need 315 size, which is present only in the bot, it is ordered individually.

Storage and operation conditions

Storing safety shoes is a responsible process. The following conditions must be observed:

- the presence of a dark enclosed space;

- the ambient temperature must be above 0 degrees Celsius (exceeding the 20-degree mark will adversely affect the quality of rubber products);

- availability of shelving or wooden shelves in the warehouse;

- requirements for relative humidity - 50-70%;

- finding overalls and safety shoes in the immediate vicinity of the heating units is unacceptable. It is allowed to keep items for wearing in relation to heating systems at a distance of one meter or more;

- close proximity to chemically aggressive environments: acids, alkalis, some liquids, technical oils can cause substances to get on the surface of products with their subsequent damage.

Important: electrically impervious shoes are operated in accordance with the rules for the use of protective equipment used in power plants. It is necessary to ensure that it does not receive mechanical damage due to the impact of hard, cutting objects, chemically aggressive substances.

In a simplified version, it should be borne in mind that boots or galoshes are worn over existing clean and dry shoes. After completion of work, rubber products are removed and left on the territory of the electrical installation. If necessary, they are cleaned of dirt and dried.

Best before date

Subject to the appropriate conditions (proper transportation, storage, operation), the shelf life of rubber products is one year, and in the Far North and remote regions up to one and a half years from the date of manufacture.

The process of verification of dielectric galoshes and boots

Electrical protective equipment is checked according to the standards of operational tests in order to avoid an accident. During the production process, safety shoes are subjected to regular and extraordinary tests. Extraordinary checks are carried out, if the inspection of safety shoes revealed any damage. Tests are carried out according to approved regulatory documents by specially trained and certified personnel.

Test dates and frequency

The frequency of checking polymer bots is at least 3 times in 12 months. In some cases, the period is extended to 6 months.Ideally, footwear testing should take place before any work in an electrical installation.

The time allotted for testing protective equipment is one minute.

Is there a need to test new bots?

Electrical protective equipment received for operation from manufacturers or from warehouses, that is, new ones, must be checked in accordance with the standards of operational tests.

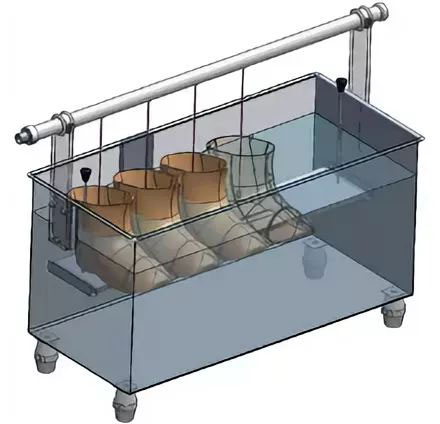

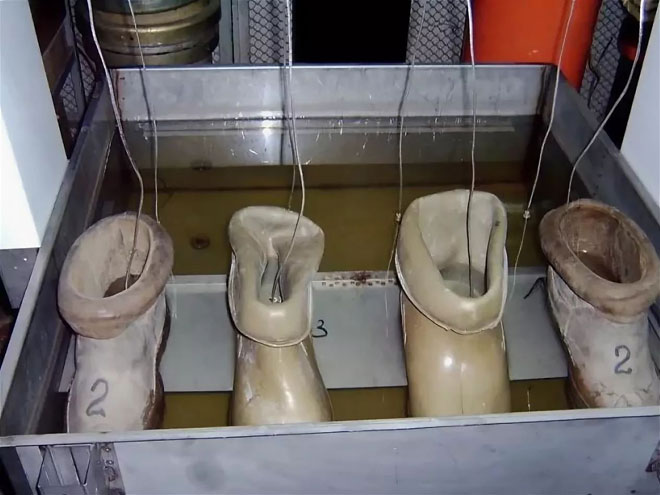

How is dielectric bot checked?

Testing can be carried out both in the laboratory and at home on a high-voltage stand. In this case, the cleanliness of the test items and the absence of visible damage are obligatory.

Important: during testing, the upper part must be left dry.

Water is poured into a vessel. The liquid is necessary for immersing the objects under study in it. In the case when boots are checked, the height of the water must be at least 45 millimeters below the edge of the lapels. For galoshes, the height of the liquid should be no more than 25 millimeters from the edge of the shoe.

A current of 2 mA for galoshes and 7.5 mA for boots is passed through the shoes. The test voltage is 3.5 kV for galoshes; 15 kV for bot.

The results of testing are recorded in the protocol, the means of protection are stamped. Safety shoes that have not passed the test are marked with a red stamp.

Similar articles: