When working with station and linear electrical equipment, great importance is attached to protecting the worker from high voltage and electric shock. For these purposes, special electrical protective equipment is used to ensure reliable security of people working on electrical installations. Complete information on the classification and list of protective equipment for work in electrical installations is contained in the "Instructions for the use and testing of protective equipment used in electrical installations" SO 153-34.03.603-2003.

Content

- 1 Electrical protective equipment: types and requirements for them

- 2 Means of protection against electric fields of increased intensity, collective and individual

- 3 Individual protection means

- 4 Procedure and general rules for the use of protective equipment

- 5 The order of storage of protective equipment

- 6 Accounting for protective equipment and monitoring their condition

Electrical protective equipment: types and requirements for them

According to the method of application, all known protective equipment (AP) is conditionally divided into those used by one person - personal protective equipment (PPE) and collective - structurally related to the production process, equipment, premises. According to their functional purpose and the effect they have, they are:

- insulating or enclosing;

- used for high-altitude operations;

- shielding.

Additional Information: According to the voltage value, these products are divided for operation in networks up to 1000 V and more than 1000 V.

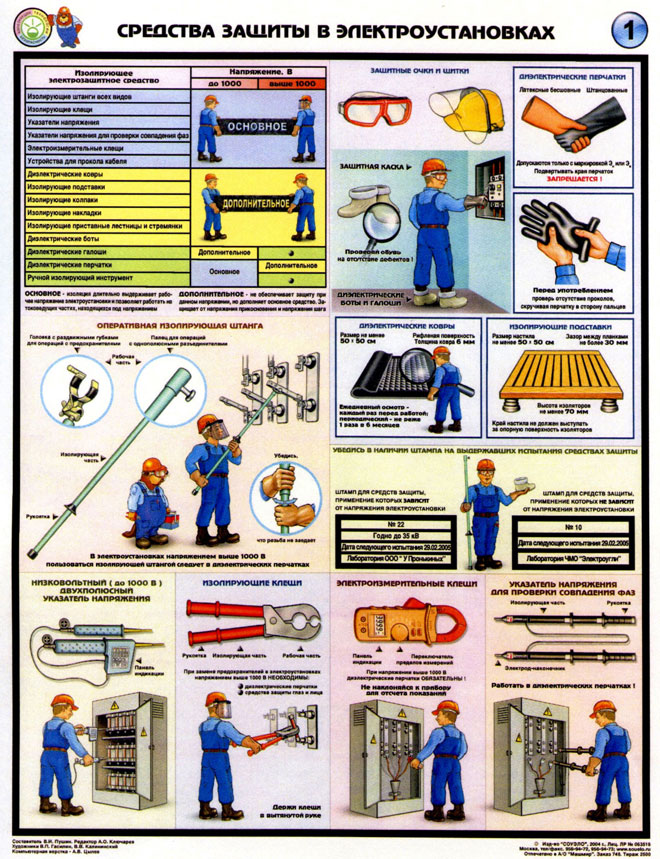

Insulating electrical protective equipment is usually divided into two types:

- Basic - the insulation of which can withstand the operating voltage of the electrical installation for a long time and allows you to work on live parts that are under voltage.

- Additional - complement the main ones, serve to protect against step voltage and touch voltage, but by themselves they do not provide protection against electric shock.

The requirements for them, as a rule, are determined by their direct purpose (the ability to withstand the voltage of the electrical installation). In addition, they must be in good working order and have a mark on the last test period. On rubber products there should be no signs of staleness, as well as cuts and punctures visible to the naked eye.

Insulating protective equipment for electrical installations with voltages above 1000 V

This type of protective equipment and working tool is represented by the following main items:

- insulating rods;

- insulating pliers;

- voltage indicators;

- devices and fixtures to ensure the safety of work during measurements and tests in electrical installations;

- special means of protection, devices and insulating devices for work under voltage in electrical installations with a voltage of 110 kV and above.

Additional categories include:

- dielectric gloves and boots, carpets and insulating pads;

- insulating caps and linings;

- transfer and potential equalization rods

- side ladders, insulating fiberglass ladders.

Insulating protective equipment for electrical installations with voltage up to 1000 V

For electrical installations with voltages up to 1000 V, the following main types of insulating ZS can be distinguished:

- insulating rods and pliers;

- voltage indicators and electrical clamps;

- gloves made on the basis of dielectric materials;

- special measuring clamps (current);

- manual insulating tool.

Additional insulating protective products include:

- insulating supports and dielectric carpets;

- dielectric galoshes;

- insulating caps, covers and linings;

- ladders, insulating fiberglass ladders.

Means of protection against electric fields of increased intensity, collective and individual

During work carried out on overhead lines and outdoor switchgear with a voltage of 330 kV and higher with an electric field strength of up to 5 kV / m, the time spent in the working area without protective equipment is not limited. When the tension value is from 5 to 25 kV/m, it is limited according to the state standard, and when the tension value is higher than 25 kV/m, it is not allowed.

Protective equipment against electric fields of increased intensity includes shielding kits used during work operations on overhead power lines (VL) or at ground level in switchgears such as outdoor switchgear. According to the method of arrangement, such protection is divided into the following types:

- removable shielding devices (installed on machines and mechanisms);

- stationary, portable and mobile shielding devices;

- individual shielding kits.

Among the described products, we single out shielding kits for individual purposes, made in the form of protective equipment worn on a person. Shielding systems for collective use are designed to protect a whole group of people. They are made of conductive material and are connected to grounded objects (protective circuit).

Individual protection means

The PPE category includes:

- protective helmets, goggles and shields;

- mittens (gloves), special protective clothing, gas masks and respirators;

- mounting belts and safety ropes.

The first products in the list are used to protect the head from mechanical shocks, as well as from current exposure in case of accidental contact with bare wires. Goggles and shields are needed in order to protect the face and eyes from the blinding light of an electric arc, particles of dirt and dust, UV and IR radiation.

The gloves used during the work provide protection of hands from unforeseen injuries, burns and cuts. Mounting belts guarantee the protection of personnel from accidental falls from a height during high-altitude work.The safety rope is designed to secure a safety belt with a carabiner in order to protect workers in case of a fall from a height when performing labor operations at a height.

Welding kits are necessary to protect the body from the dangerous effects of an electric arc. They include a helmet with a protective face shield, a heat-resistant balaclava and thick gloves.

Procedure and general rules for the use of protective equipment

Each worker carrying out work in an electrical installation must be provided with the necessary protective equipment and trained in the rules for their use, and must also use them and comply with the following general requirements:

- use only those products that have a label (indicate the manufacturer, name or type of product, date of issue and test stamp);

- before the next use, the personnel working on the electrical installation must check the serviceability of the protective equipment used, the absence of external damage and contamination and, according to the stamp, the expiration date;

- in the event that the protective equipment is found to be unsuitable for use, it is withdrawn, which is recorded in the journal of accounting and maintenance of protective equipment or in operational documentation.

When working, do not touch directly the working area of the product, as well as that part of the insulation that is located behind the limit stop.

The order of storage of protective equipment

The effectiveness of electrical protection equipment depends on many factors, including compliance with the rules for their storage. In this case, the following mandatory requirements must be met:

- it is necessary to store protective equipment indoors, in conditions that ensure their serviceability and suitability for use;

- protective equipment made of rubber and polymeric materials is stored in cabinets or on racks separately from the tool and be protected from the effects of acids, alkalis, oils, etc., as well as from exposure to sunlight and heat radiation from heating devices;

- protective equipment is placed in specially equipped places at the entrance to the premises, on control panels.

It should also be noted that the storage of protective equipment is allowed only in a dry form.

Accounting for protective equipment and monitoring their condition

All electrical protective equipment in use must be numbered. The following items are an exception:

- protective helmets, dielectric mats;

- special insulating supports;

- safety posters and protective barriers;

- rods for transfer and potential equalization.

Important note: when numbering products, it is allowed to use their serial numbers.

Numbers are assigned individually for each type of AP, taking into account the specific conditions of their operation. The inventory number is either stamped on the metal parts of the products, or applied with bright paint in a clearly visible place. It is also allowed to place it on a special tag attached to the protective equipment itself.

If the equipment or tool contains several parts in its design, a separate tag is hung on each of them. In the relevant divisions of enterprises associated with the maintenance of electrical equipment, it is mandatory to have a register of all the means of protection available in them, including those issued for individual use.

Their total cash and current condition are controlled by visual inspections, the frequency of which is set at the rate of at least once every six months. For portable grounding, this figure is at least once a quarter. The responsible employee who is entrusted with monitoring their condition, after inspection, must record the result in the appropriate column of a special journal.

Similar articles: