A key element of the mobility of electronic devices is the rechargeable battery (ACB). Growing demands to ensure their longest autonomy stimulate continuous research in this area and lead to the emergence of new technological solutions.

The widely used nickel-cadmium (Ni-Cd) and nickel-metal hydride (Ni-MH) batteries have an alternative - first lithium batteries, and then more advanced lithium-ion (Li-ion) batteries.

Content

History of appearance

The first such batteries appeared in the 70s. last century. They immediately gained demand due to more advanced characteristics. The anode of the elements was made of metallic lithium, the properties of which made it possible to increase the specific energy. This is how lithium batteries were born.

The new batteries had a significant drawback - an increased risk of explosion and ignition.The reason lay in the formation of a lithium film on the electrode surface, which led to a violation of temperature stability. At the moment of maximum load, the battery could explode.

The refinement of the technology has led to the abandonment of pure lithium in battery components in favor of using its positively charged ions. The lithium-ion battery proved to be a good solution.

This type of ion battery is characterized by higher safety, which is obtained at the expense of a slight decrease in energy density, but constant technological progress has made it possible to reduce the loss in this indicator to a minimum.

Device

The introduction of lithium-ion batteries into the consumer electronics industry received a breakthrough after the development of a battery with a carbon material (graphite) cathode and a cobalt oxide anode.

In the process of battery discharge, lithium ions are removed from the cathode material and are included in the cobalt oxide of the opposite electrode; when charging, the process proceeds in the opposite direction. Thus, lithium ions create an electric current, moving from one electrode to another.

Li-Ion batteries are produced in cylindrical and prismatic versions. In a cylindrical structure, two strips of flat electrodes, separated by an electrolyte-impregnated material, are rolled up and placed in a sealed metal case. The cathode material is deposited on aluminum foil, and the anode material is deposited on copper foil.

A prismatic battery design is obtained by stacking rectangular plates on top of each other. This shape of the battery makes it possible to make the layout of the electronic device more dense. Prismatic batteries with rolled electrodes twisted into a spiral are also produced.

Operation and service life

Long, full and safe operation of lithium-ion batteries is possible if the operating rules are observed, neglecting them will not only shorten the life of the product, but can lead to negative consequences.

Exploitation

The key requirement for the operation of Li-Ion batteries concerns temperature - overheating should not be allowed. High temperatures can cause maximum harm, and the cause of overheating can be both an external source and stressful modes of charging and discharging the battery.

For example, heating up to 45°C leads to a decrease in the ability to hold a battery charge by 2 times. This temperature is easily reached when the device is exposed to the sun for a long time or when running energy-intensive applications.

If the product overheats, it is recommended to place it in a cool place, it is better to turn it off and remove the battery.

For the best battery performance in the summer heat, you should use the energy-saving mode, which is available on most mobile devices.

Low temperatures also have a negative effect on ion batteries; at temperatures below -4°C, the battery can no longer deliver full power.

But cold is not as harmful to Li-Ion batteries as heat, and most often does not cause permanent damage. Despite the fact that after warming up to room temperature, the working properties of the battery are completely restored, you should not forget about the decrease in capacity in the cold.

Another recommendation for the use of Li-Ion batteries is to prevent them from being deeply discharged. Many older generation batteries had a memory effect that required them to be discharged to zero and then fully charged.Li-Ion batteries do not have this effect, and isolated cases of complete discharge do not lead to negative consequences, but constant deep discharge is harmful. It is recommended to connect the charger when the charge level is 30%.

Life time

Improper operation of Li-Ion batteries can reduce their service life by 10-12 times. This period directly depends on the number of charging cycles. It is believed that Li-Ion type batteries can withstand from 500 to 1000 cycles, taking into account full discharge. A higher percentage of remaining charge before the next charge significantly increases battery life.

Since the duration of the Li-Ion battery life is largely determined by the operating conditions, it is impossible to give an exact service life for these batteries. On average, a battery of this type can be expected to last 7-10 years if the required regulations are followed.

Charging process

When charging, avoid excessively long connection of the battery to the charger. Normal operation of a lithium-ion battery takes place at a voltage not exceeding 3.6 V. Chargers supply 4.2 V to the battery input during charging. If the charge time is exceeded, unwanted electrochemical reactions may begin in the battery, which will lead to overheating with all ensuing consequences.

The developers took into account such a feature - the safety of the charge of modern Li-Ion batteries is controlled by a special built-in device that stops the charging process when the voltage rises above the permissible level.

For lithium batteries, the two-stage charging method is correct.At the first stage, the battery must be charged, providing a constant charging current, the second stage must be carried out with a constant voltage and a gradual decrease in the charging current. Such an algorithm is implemented in hardware in most household chargers.

Storage and disposal

A lithium-ion battery can be stored for a long time, self-discharge is 10-20% per year. But at the same time, a gradual decrease in the characteristics of the product (degradation) occurs.

It is recommended to store such batteries in a place protected from moisture, at a temperature of +5 ... + 25 ° С. Strong vibrations, impacts and proximity to an open flame are unacceptable.

The process of recycling lithium-ion cells must be carried out at specialized enterprises that have the appropriate license. About 80% of the materials from recycled batteries can be reused in the manufacture of new batteries.

Safety

A lithium-ion battery, even of a miniature size, is fraught with the risk of explosive spontaneous combustion. This feature of this type of battery requires compliance with safety measures at all stages, from development to production and storage.

To improve the safety of Li-Ion batteries during manufacture, a small electronic board is placed in their case - a monitoring and control system that is designed to eliminate overloads and overheating. The electronic mechanism increases the resistance of the circuit when the temperature rises above a predetermined limit. Some battery models have a built-in mechanical switch that breaks the circuit when the pressure inside the battery rises.

Also, a safety valve is often installed in battery cases to relieve pressure in case of emergency.

Pros and cons of lithium batteries

The advantages of this type of battery are:

- high energy density;

- no memory effect;

- long service life;

- low self-discharge rate;

- no need for maintenance;

- ensuring constant operating parameters over a relatively wide temperature range.

It has a lithium battery and disadvantages, these are:

- risk of spontaneous combustion;

- higher cost than its predecessors;

- the need for a built-in controller;

- undesirability of deep discharge.

Technologies for the production of Li-Ion batteries are constantly being improved, many shortcomings are gradually becoming a thing of the past.

Application area

The high energy density of lithium-ion batteries determines their main area of application - mobile electronic devices: laptops, tablets, smartphones, video cameras, cameras, navigation systems, various built-in sensors and a number of other products.

The existence of a cylindrical form factor of these batteries allows them to be used in flashlights, landline phones and other devices that previously consumed power from disposable batteries.

The lithium-ion principle of building a battery has several varieties, the types differ in the type of materials used (lithium-cobalt, lithium-manganese, lithium-nickel-manganese-cobalt-oxide, etc.). Each of them has its own scope.

In addition to mobile electronics, a group of lithium-ion batteries is used in the following areas:

- hand-held power tools;

- portable medical equipment;

- uninterruptible power supplies;

- security systems;

- emergency lighting modules;

- solar powered stations;

- electric vehicles and electric bicycles.

Considering the constant improvement of lithium-ion technology and the success in creating high-capacity batteries with small sizes, it is possible to predict the expansion of applications for such batteries.

Marking

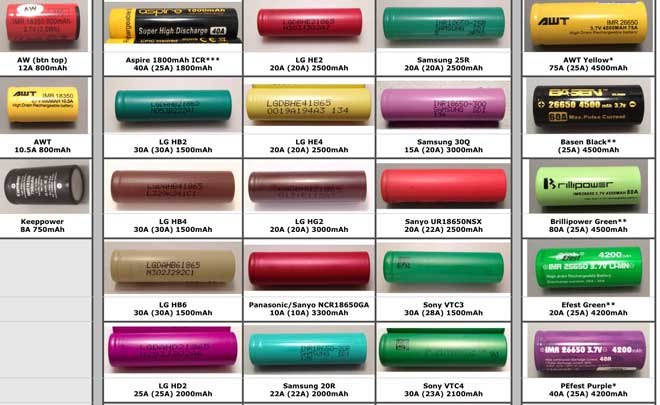

The parameters of lithium-ion batteries are printed on the body of the product, while the coding used may differ significantly for different sizes. A common battery labeling standard for all manufacturers has not yet been developed, but it is still possible to deal with the most important parameters on your own.

The letters in the marking line indicate the type of cell and the materials used: the first letter I means lithium-ion technology, the next letter (C, M, F or N) specifies the chemical composition, the third letter R means that the cell is rechargeable (Rechargeable).

The numbers in the size name indicate the size of the battery in millimeters: the first two numbers are the diameter, and the other two are the length. For example, 18650 indicates that the diameter is 18 mm and the length is 65 mm, 0 indicates a cylindrical form factor.

The last letters and numbers in the series are the container markings specific to each manufacturer. There are also no uniform standards for indicating the date of manufacture.